Main reducer assembly with high transmission efficiency

A technology of transmission efficiency and main reducer, applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems of power loss, large oil volume, mechanical power loss, etc., to reduce the amount of lubricating oil, improve transmission efficiency, The effect of reducing oil churning power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

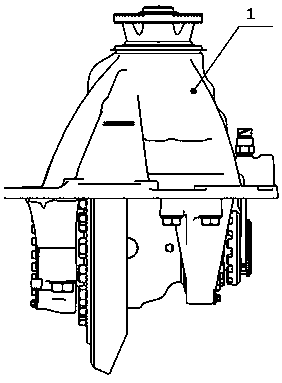

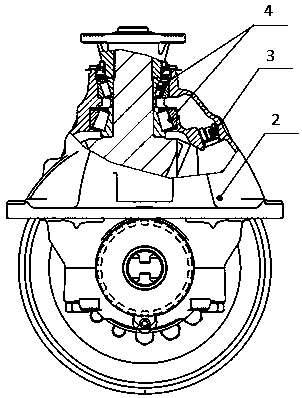

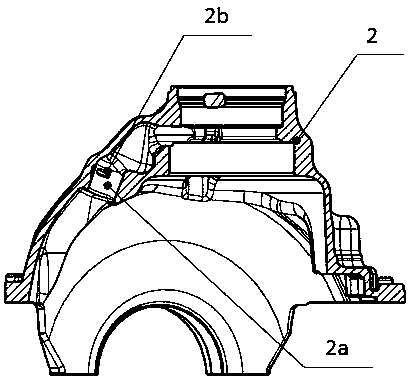

[0018] Such as Figure 1 to Figure 7 shown. The present invention is a main reducer assembly with high transmission efficiency. Cone bearing 4, differential assembly, reducer housing 2 are provided with oil passages, and the oil passages include gear lubricating oil passages. A cylindrical socket 2a is cast on the gear lubricating oil passage, and two inline slots 2b, 2c are symmetrically opened on the walls of the two sides of the cylindrical socket 2a for assembling the fuel saving plug 3 . When assembling the oil-saving plug 3, it is necessary to insert the socket 3c of the oil-saving plug 3 through a special tool, and put the oil-saving plug 3 into the cylindrical socket 2a in the lubricating oil passage of the reducer housing. The oil-saving plug 3 has The two in-line ferrules 3a, 3b respectively matched with the two in-line card slots 2b, 2c can be fixed in the lubricating oil channel of the reducer housing, and the oil-saving plug 3 is provided with a through hole 3d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com