Auxiliary structure for gearbox capable of lowering gearbox oil stirring power loss

A power loss and auxiliary structure technology, applied in the direction of gear lubrication/cooling, etc., can solve the problems of large oil churning power loss, increased lubricating oil, and reduced transmission efficiency, and achieve the effect of reducing oil churning power loss and lowering the height of the oil level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

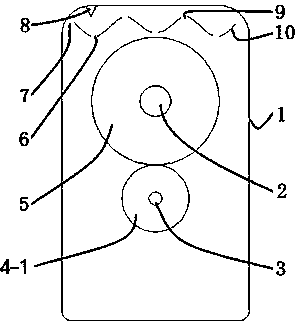

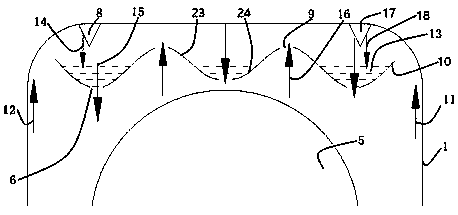

[0026] The invention provides an auxiliary structure for a transmission that can reduce the oil churning power loss of the transmission. By arranging an oil storage and a mechanism for adding lubricating oil at the positioning point on the upper part of the transmission, the height of the lubricating oil page during the operation of the transmission is reduced, and the power loss of the gear churning oil is reduced. , suitable for traditional automobiles and new energy automobile gear transmissions, also suitable for various gear transmissions, especially suitable for automotive transmissions.

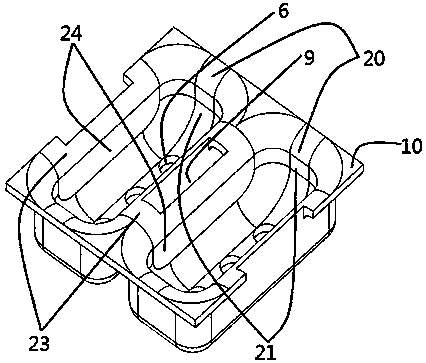

[0027] Specific embodiments of the present invention such as Figure 1-6In the shown transmission case 1, the first lower gear 4-1, the second lower gear 4-2, the third lower gear 4-3, the fourth lower gear 4-4 and the fifth lower gear 4- 5. A total of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com