Hydraulic-hydraumatic comprehensive driving axle gear box body

A technology for axle gearboxes and boxes, which is applied in the directions of transmission boxes, transmission parts, gear lubrication/cooling, etc., which can solve the problems that drive axle gearboxes cannot be shared, affect the efficiency of line operation, and complicate power transmission systems. Compact, takes up little space, and improves sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

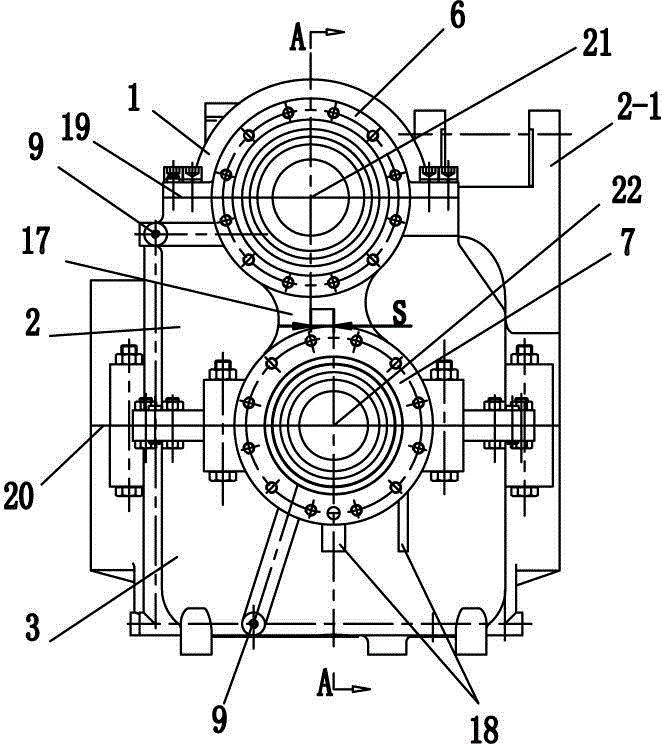

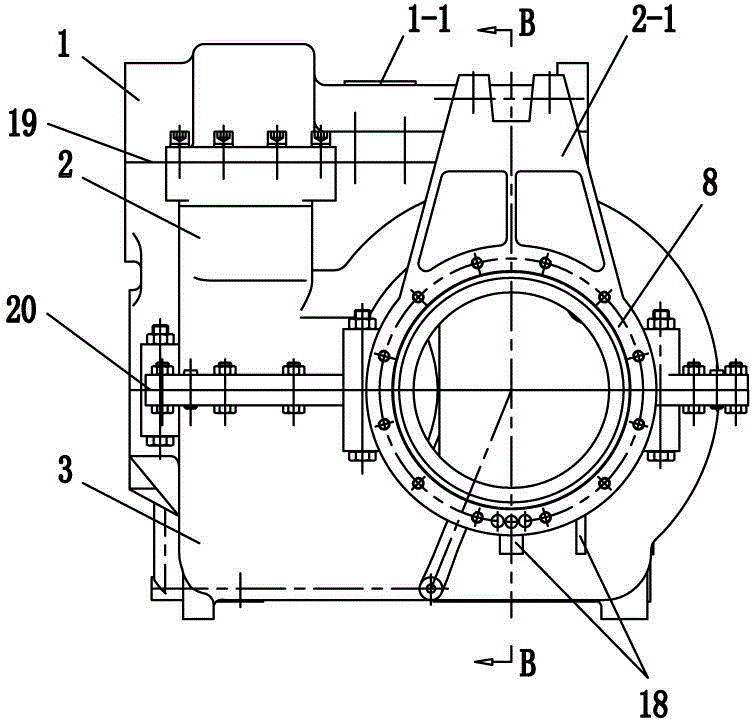

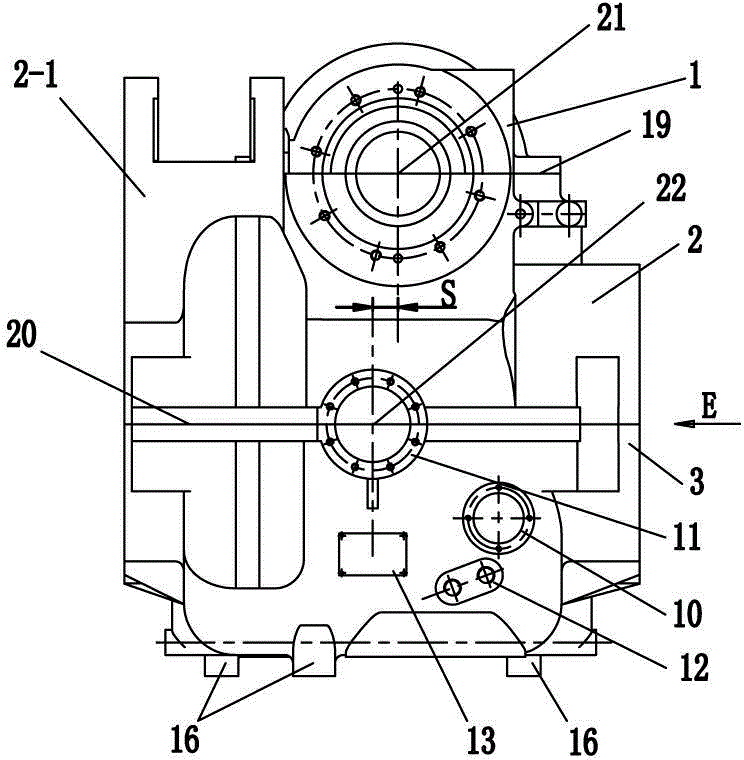

[0026] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a hydraulic-hydraulic comprehensive transmission axle gearbox box body, including a box cover 1, an upper box body 2 and a lower box body 3, the box cover 1, The upper box body 2 and the lower box body 3 are fixedly connected by bolts to form a box body, and the box body is provided with a pull arm mounting seat 2-1, and the box body is provided with a motor mounting flange seat 4, and a motor input spline shaft bearing seat 5. The input gear shaft bearing seat 6, the intermediate shaft bearing seat 7 and the output shaft bearing seat 8; the box has an upper split surface 19 and a lower split surface 20, and the upper split surface 19 and the lower split surface 20 are respectively parallel to the horizontal plane; the motor mounting flange seat 4, the motor input spline shaft bearing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com