An oil throwing structure in a transmission gearbox housing and its transmission

A technology for gearboxes and transmissions, which is applied in the directions of gear lubrication/cooling, belts/chains/gears, transmission parts, etc. It can solve problems such as increased kinetic energy loss, difficulty in obtaining lubrication, and increased weight of the transmission, so as to improve lubrication conditions, Simple structure and better lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention is further detailed in conjunction with the accompanying drawings and specific examples.

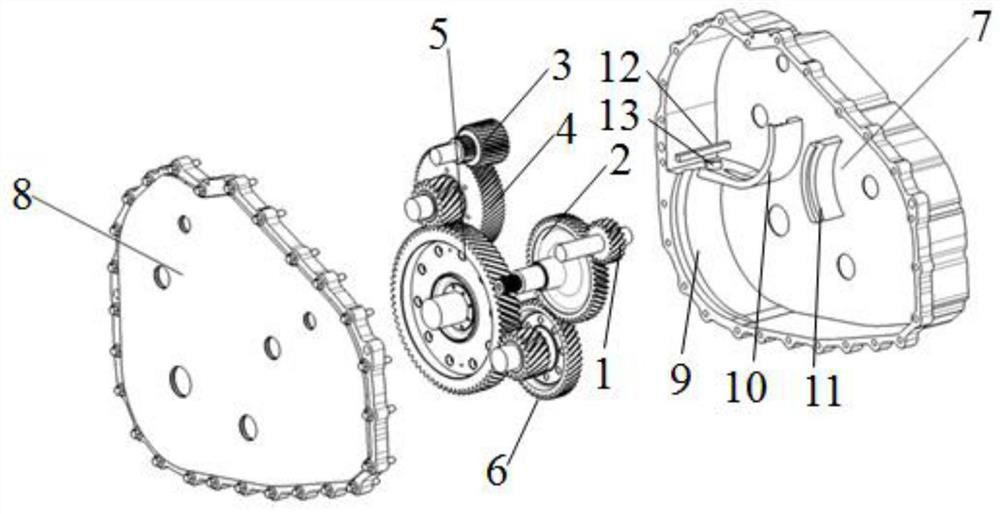

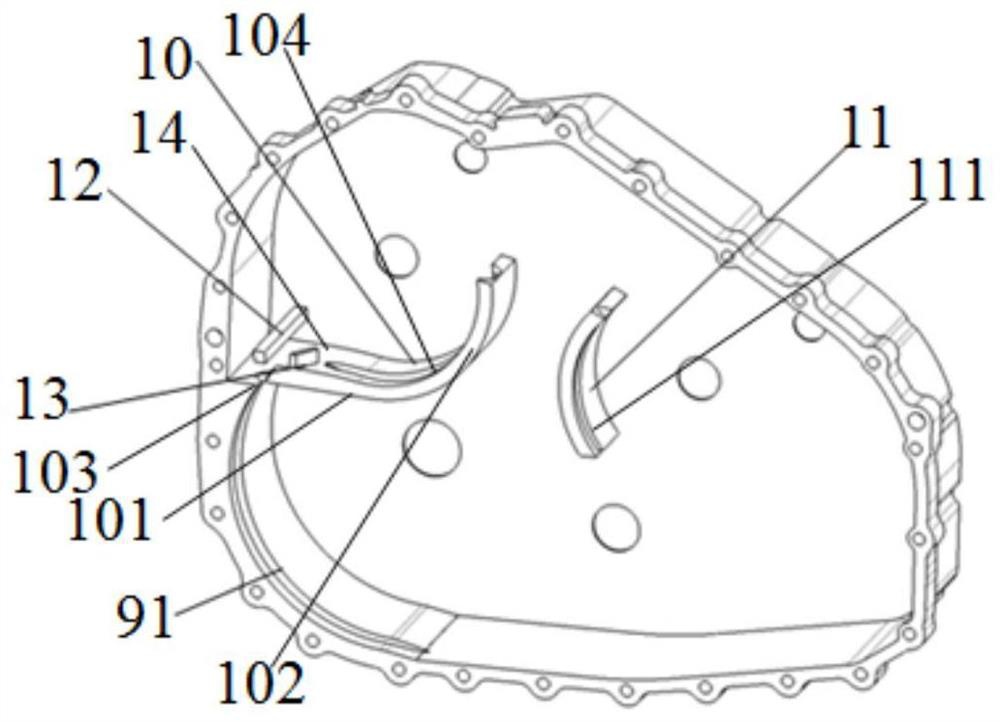

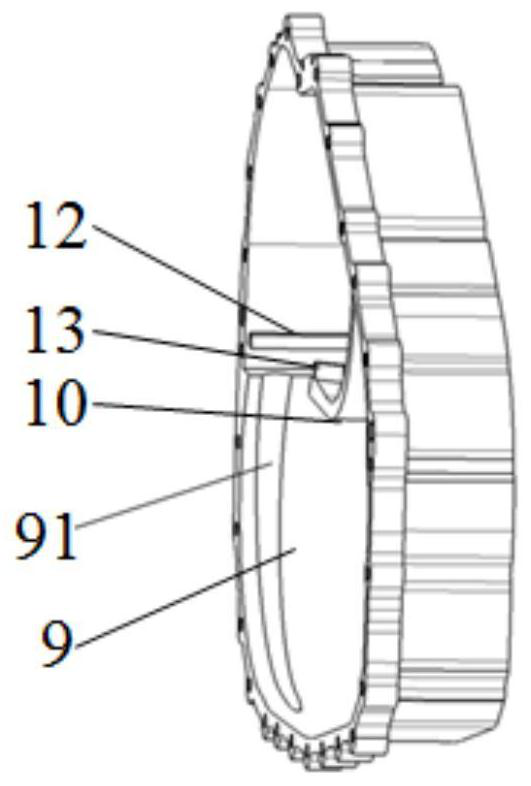

[0037]Such asFigure 1-9As shown, the present invention provides an oil structure in a transmission gearbox housing comprising a generator gear 1, an engine gear 2, a drive motor gear 3, an intermediate shaft gear 4, a differential gear 5, a clutch gear 6. The housing 7 and the housing cover 8 mounted with the housing 7, the inner wall of the housing 7 is provided with a first 甩 油 挡 9 having a lubrication gap between the differential gear 5, forming a lubrication gap between 4 intermediate shaft gears 4. The second oil baffle 10, the third 甩 油 挡 11 forms a lubrication gap between the engine gear 2; the first 甩 油 挡 板 9 extends upward from the minimum direction of the differential gear 5 to the second The oil baffle 10 is connected, and the second oil retaining plate 10 is provided with a oil mechanism to introduce a portion of the lubricating oil splashing from the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com