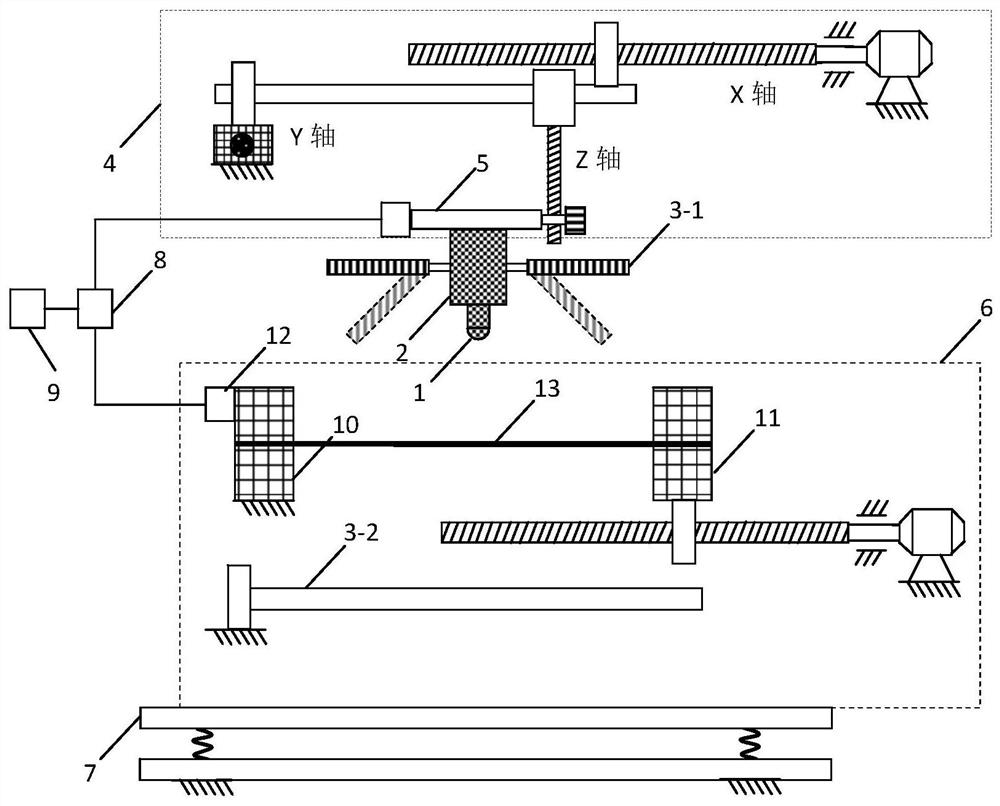

Apparatus and method for reflective measurement of fiber bundle alignment uniformity and fracture morphology

A measuring device and fiber bundle technology, which is applied in the field of optical measurement, fiber bundle fracture form and orientation degree reflective measuring device, can solve the problems of inaccuracy, etc., and achieve the effect of improving accuracy, unique innovation, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

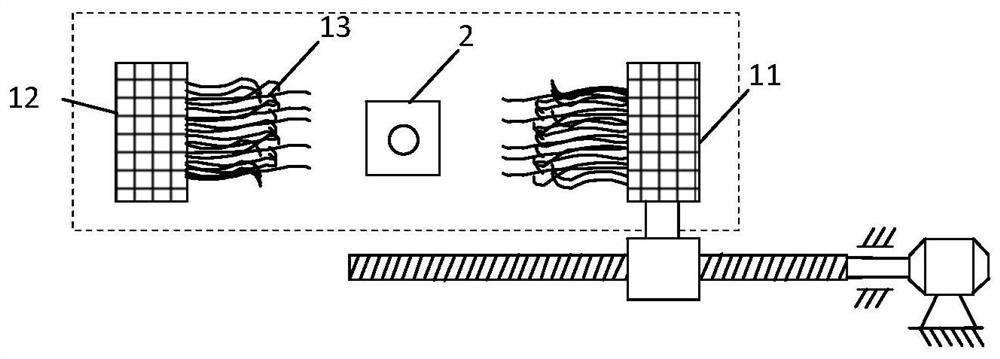

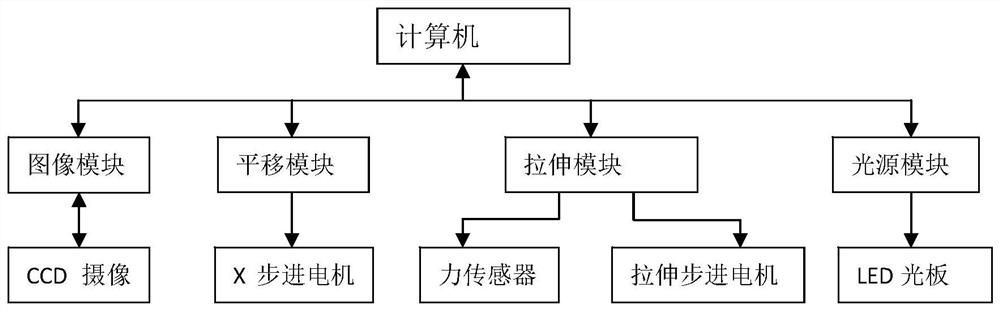

Method used

Image

Examples

Embodiment 1

[0050] The sample is tested with cotton fiber bundles, the tensile speed is 10mm / min, the speed of the stepping motor is 10r / min, and the distance is 10mm. Experimental conditions: temperature 20°C, relative humidity 65%.

Embodiment 2

[0052] The sample is tested with 66 combed wool (2114um), the tensile speed is 10mm / min, the speed of the stepping motor is 10r / min, and the distance is 10mm. Experimental conditions: temperature 20°C, relative humidity 65%.

Embodiment 3

[0054] The sample is tested with Kevlar filament, the tensile speed is 10mm / min, the stepper motor speed is 10r / min, and the distance is 10mm. Experimental conditions: temperature 20°C, relative humidity 65%.

[0055] Test results such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com