A Calculation Method of Joint Surface Roughness Based on Shape Correction

A calculation method and roughness technology, applied in design optimization/simulation, special data processing applications, etc., can solve the problems of enlarged error, large roughness coefficient description error, no consideration of joint surface undulation shape, etc., and achieve accurate calculation results , wide range of applications, the effect of reducing the final error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

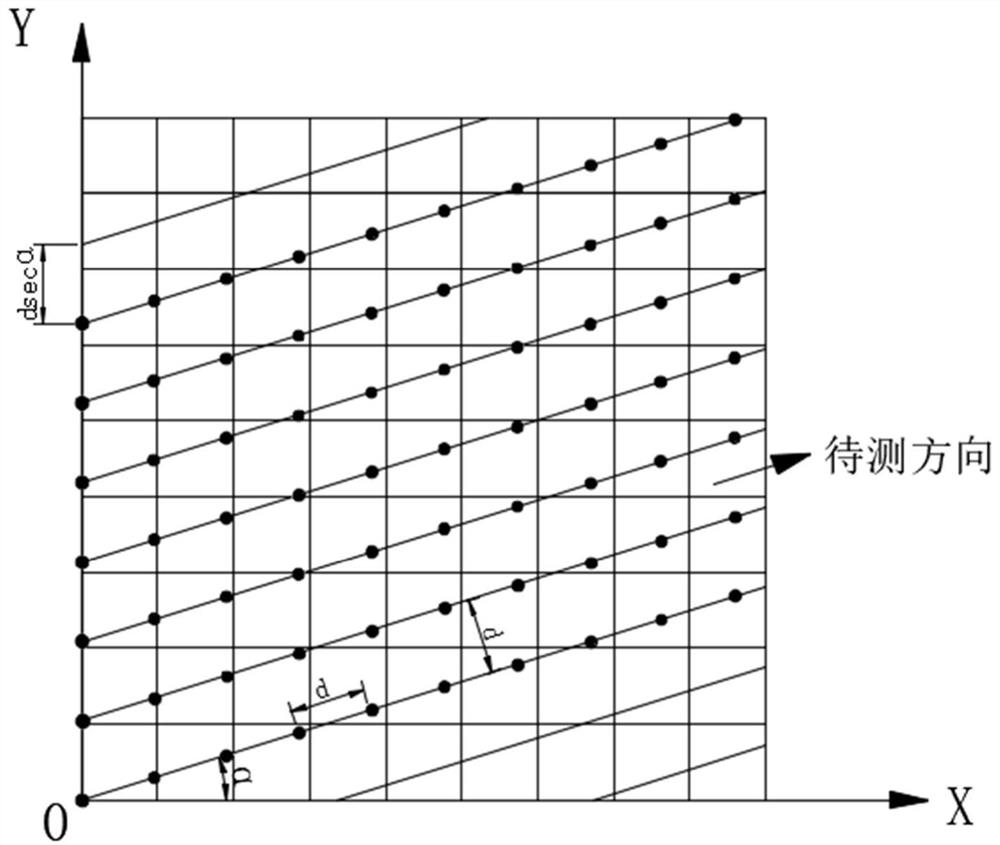

[0044] The present invention designs a joint surface roughness calculation method based on shape correction, which calculates the rock joint surface based on the roughness of the entire joint surface rather than a single profile curve, and fully considers the influence of factors such as the slope and width of the rock joint surface protrusion roughness, the method includes the following steps:

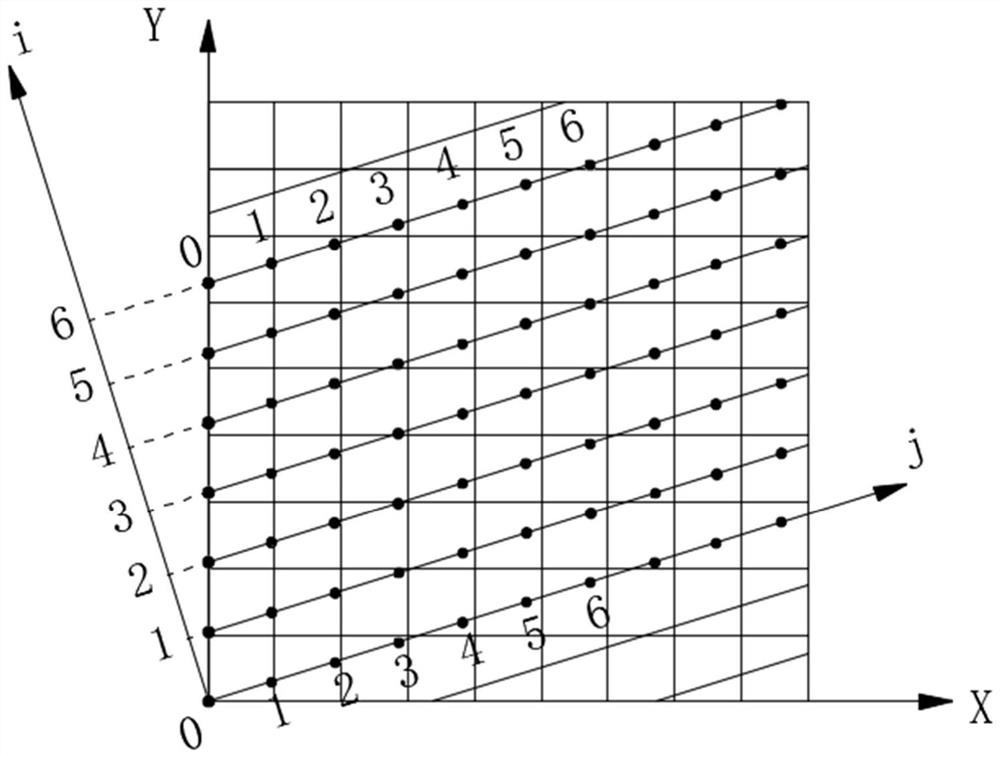

[0045] Step 1. On the rock joint surface to be measured, establish an x-y coordinate system; it is possible but not limited to place the rock joint surface in the first quadrant of the coordinate system, such as figure 1 shown.

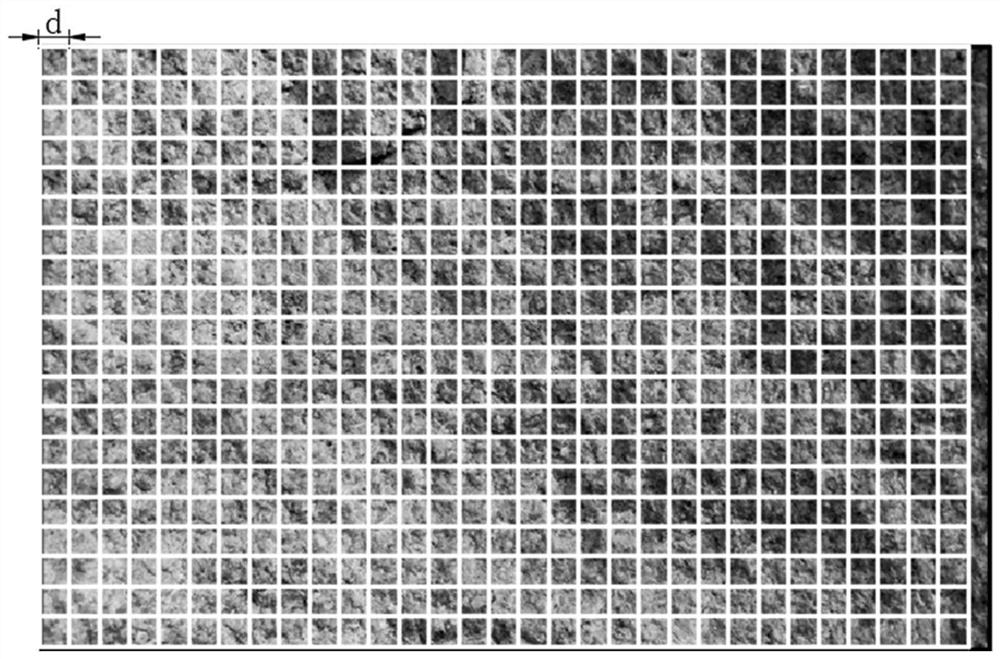

[0046] Step 2. Draw grid lines that are parallel to the x-axis and y-axis in the established x-y coordinate system and have a spacing of d, so as to obtain the grid and grid points, that is, draw the grid, and set the grid spacing to d. This imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com