Multistage hull turning tool

A technology of wagons and knives, which is applied in the field of multi-level wagon knives, can solve the problems of high maintenance costs, easily damaged CNC lathes, and low production efficiency, and achieve the effects of convenient and fast operation, saving production costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

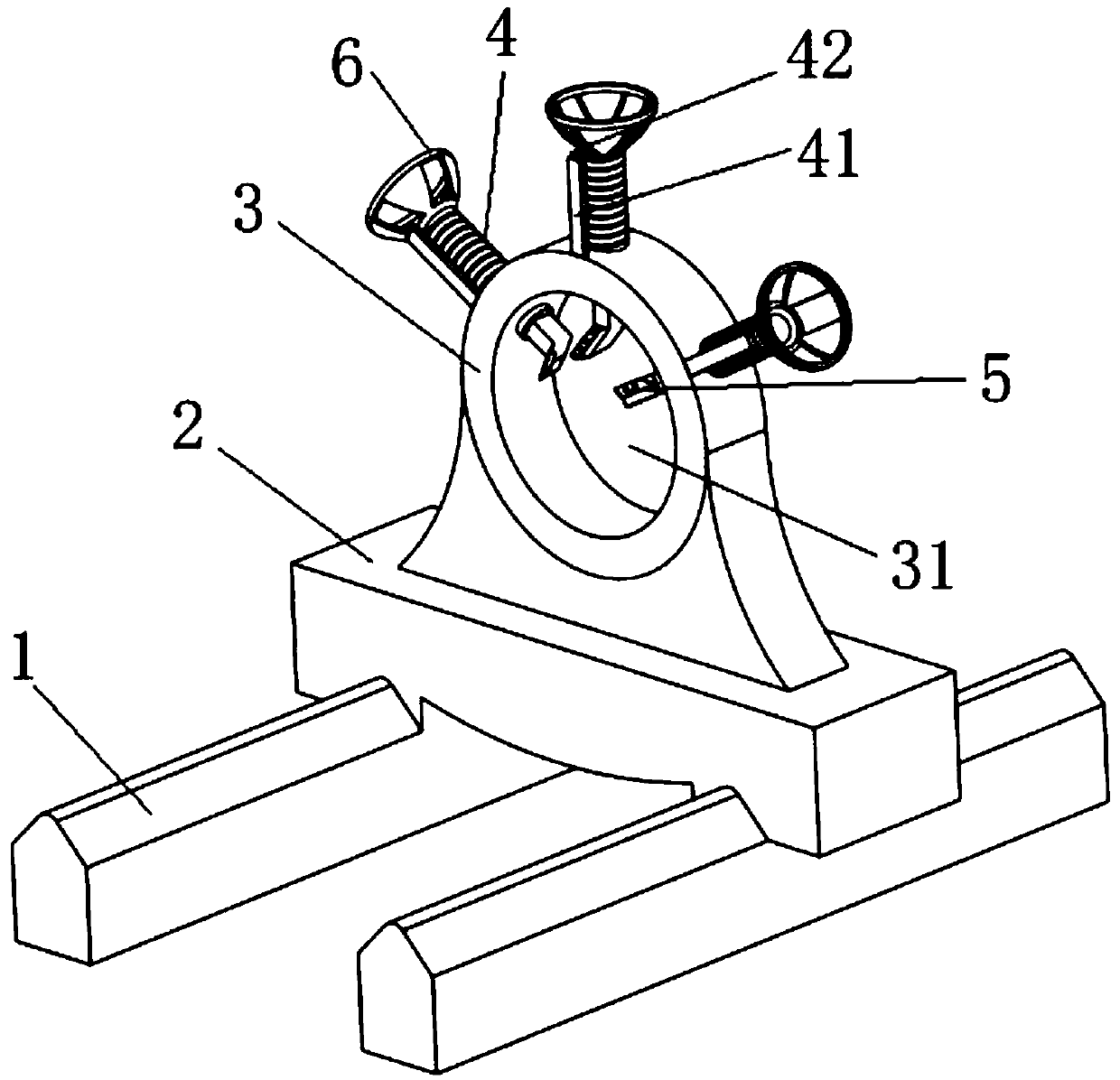

[0025] Such as Figure 1-2 As shown, a tool for multi-stage wagons includes a guide rail 1, a support 2 positioned on the guide rail 1 and capable of sliding along the guide rail 1, a tool rest 3 mounted on the support 2, at least two The adjustment mechanism 4 installed on the knife rest 3 and the knife body 5 located at the end of the adjustment mechanism 4;

[0026] The tool holder 3 is ring-shaped, and a through hole 31 is provided inside it, and the workpiece to be wagon passes through the through hole 31;

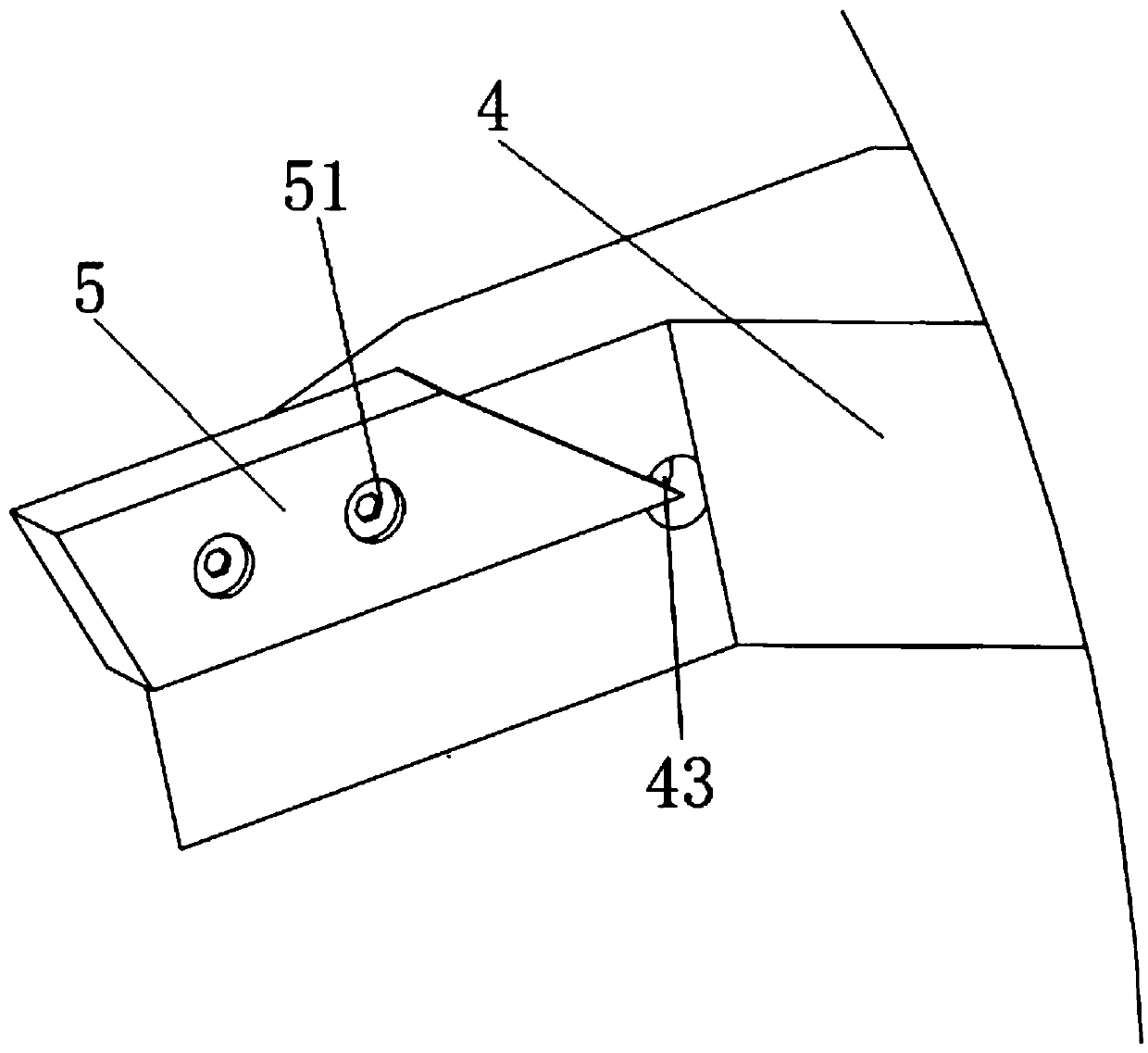

[0027] The adjustment mechanism 4 runs through the tool holder 3 and extends into the through hole 31, which is distributed along the circumferential direction of the tool holder 3, and different adjustment mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com