Control method and control system for preventing backward tipping of dump truck bed

A control method and control system technology, applied in the direction of loading and unloading vehicles, motor vehicles, vehicles used for freight, etc., can solve the problems of reducing the service life of hydraulic cylinders, turning over the whole vehicle, analysis and judgment, etc., to prevent the rear of the carriage Turn over, prevent excessive pulling out of the cylinder, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

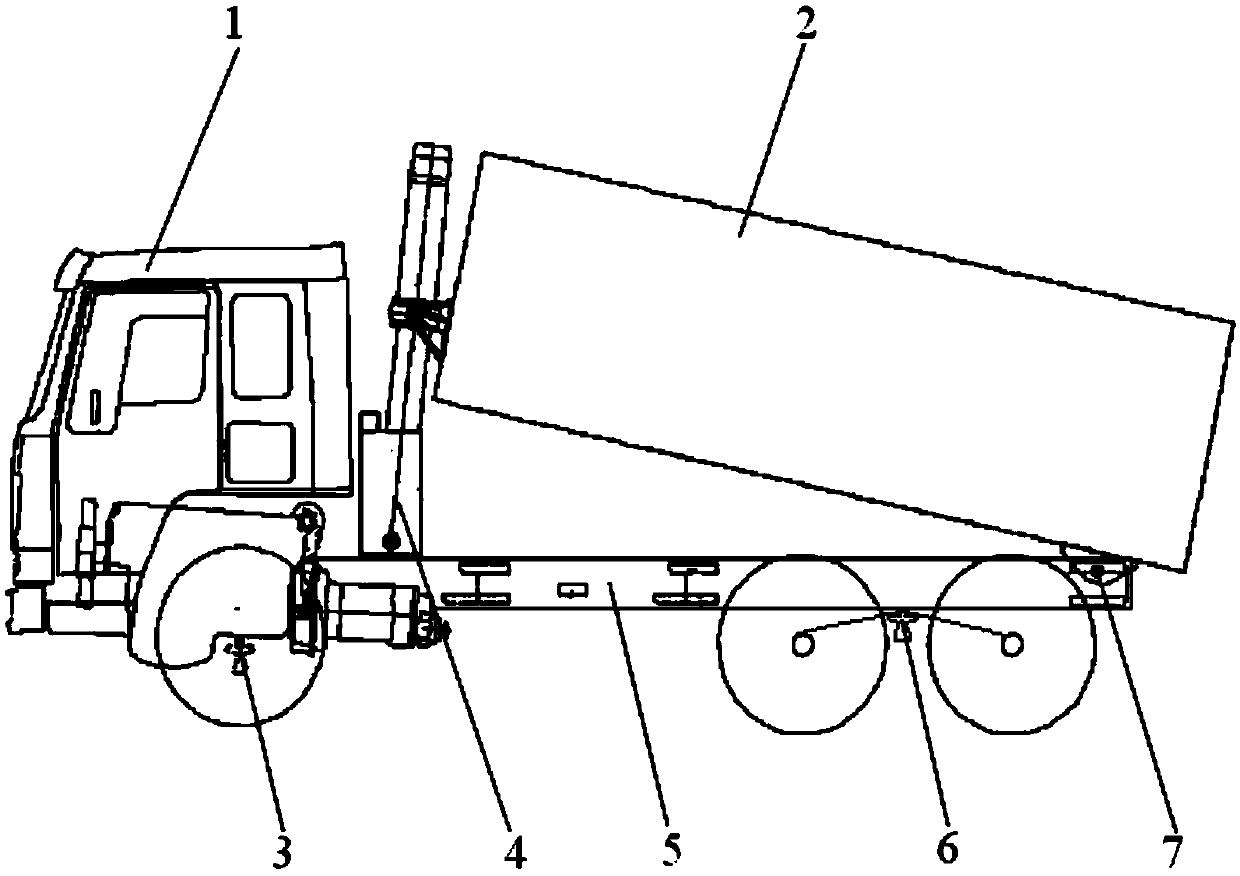

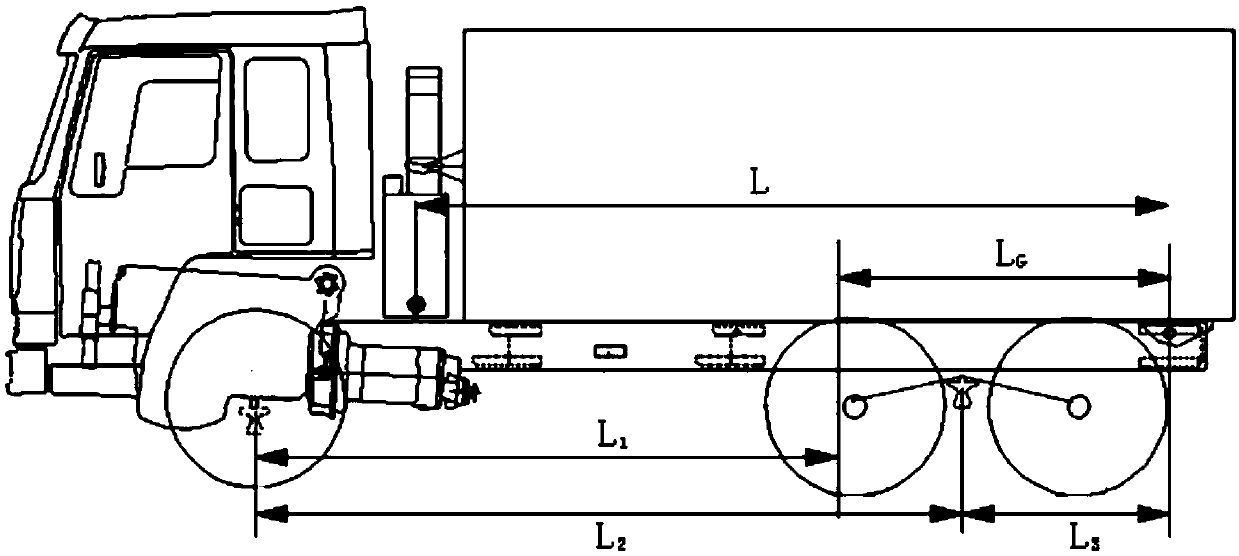

[0035] refer to Figure 1-4 , a dump truck provided in this embodiment includes a driver's cab 1, a chassis 5, a carriage 2, and a hydraulic cylinder lifting system 4, and the dump truck is provided with a control system for preventing the carriage from turning over, and the control system includes: a first detection Device 8, warning device 14, display device 13, control module, described warning device 14, display device 13 and control module are arranged in cab 1, and described first detecting device 8 is installed on described dump truck, and described control The modules are respectively connected with the first detection device 8 , the alarm device 14 and the display device 13 . Specifically, the first detection device 8 includes a pressure sensor I installed on the front axle 3 and the rear axle 6 of the dump truck for detecting the load value of the front axle and the load value of the rear axle.

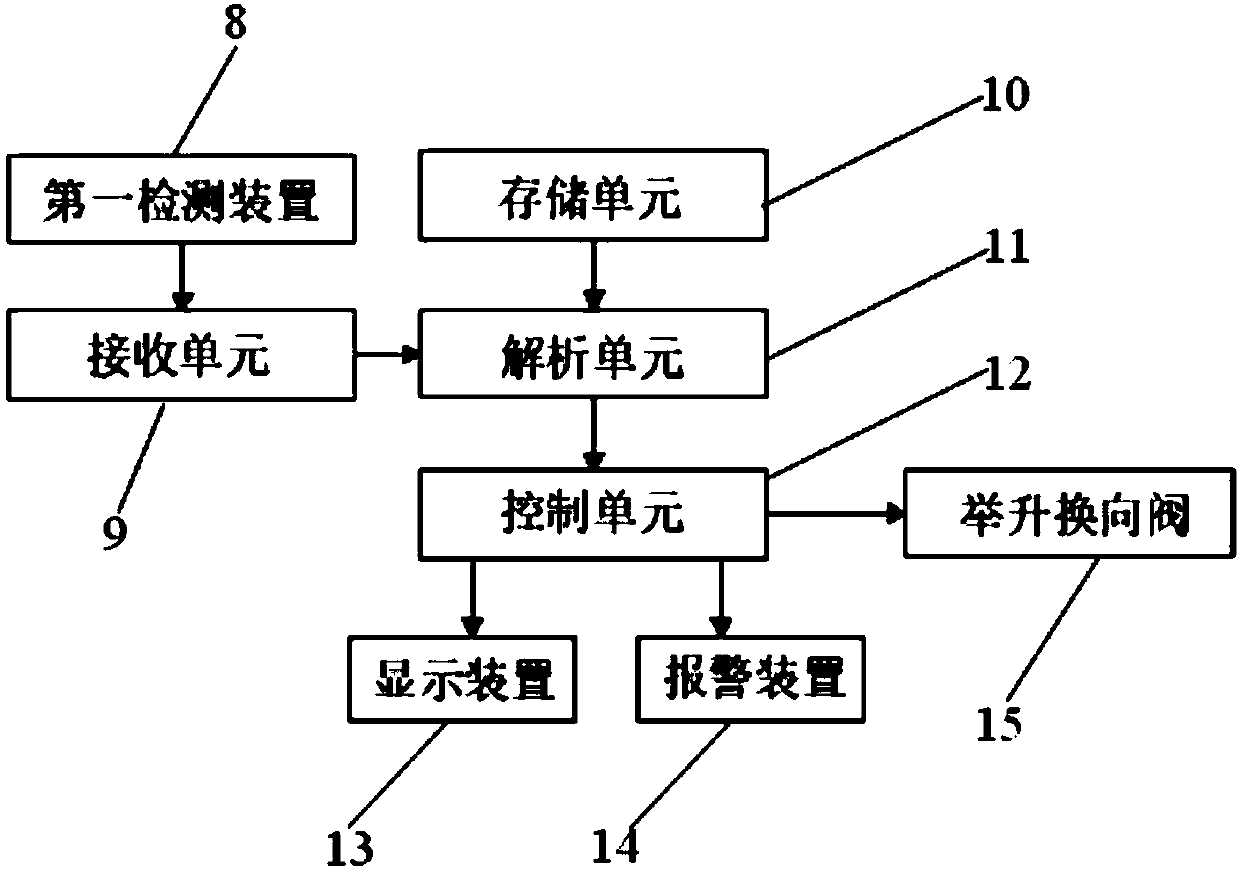

[0036] In this embodiment, the control module includes a receiving uni...

Embodiment 2

[0043] refer to Figure 1-3 and Figure 5-6In this embodiment, the second detection device 16 is added on the basis of embodiment 1, and the control module is respectively connected with the first detection device 8, the second detection device 16, the alarm device 14, the display device 13, and the hydraulic cylinder lifting system 4 . Specifically, the first detection device 8 includes a pressure sensor I, and the pressure sensor I is installed on the front axle 3 and the rear axle 6 of the dump truck for detecting the load value of the front axle and the load value of the rear axle; the second detection device 16 includes a pressure sensor II, the pressure sensor II is installed at the cylinder oil inlet port of the hydraulic cylinder, and is used to detect the pressure value of the hydraulic cylinder,

[0044] In this embodiment, the control module includes a receiving unit 9, a storage unit 10, an analysis unit 11, and a control unit 12, and the receiving unit 9 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com