Hot-dip galvanizing cosolvent tank capable of achieving full contact

A hot-dip galvanizing and co-solvent technology, applied in hot-dip galvanizing co-solvent tank and hot-dip galvanizing field, can solve the problems of insufficient contact, insufficient contact between co-solvent and workpiece, affecting the effect of hot-dip galvanizing, etc. , to achieve the effect of ensuring the contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

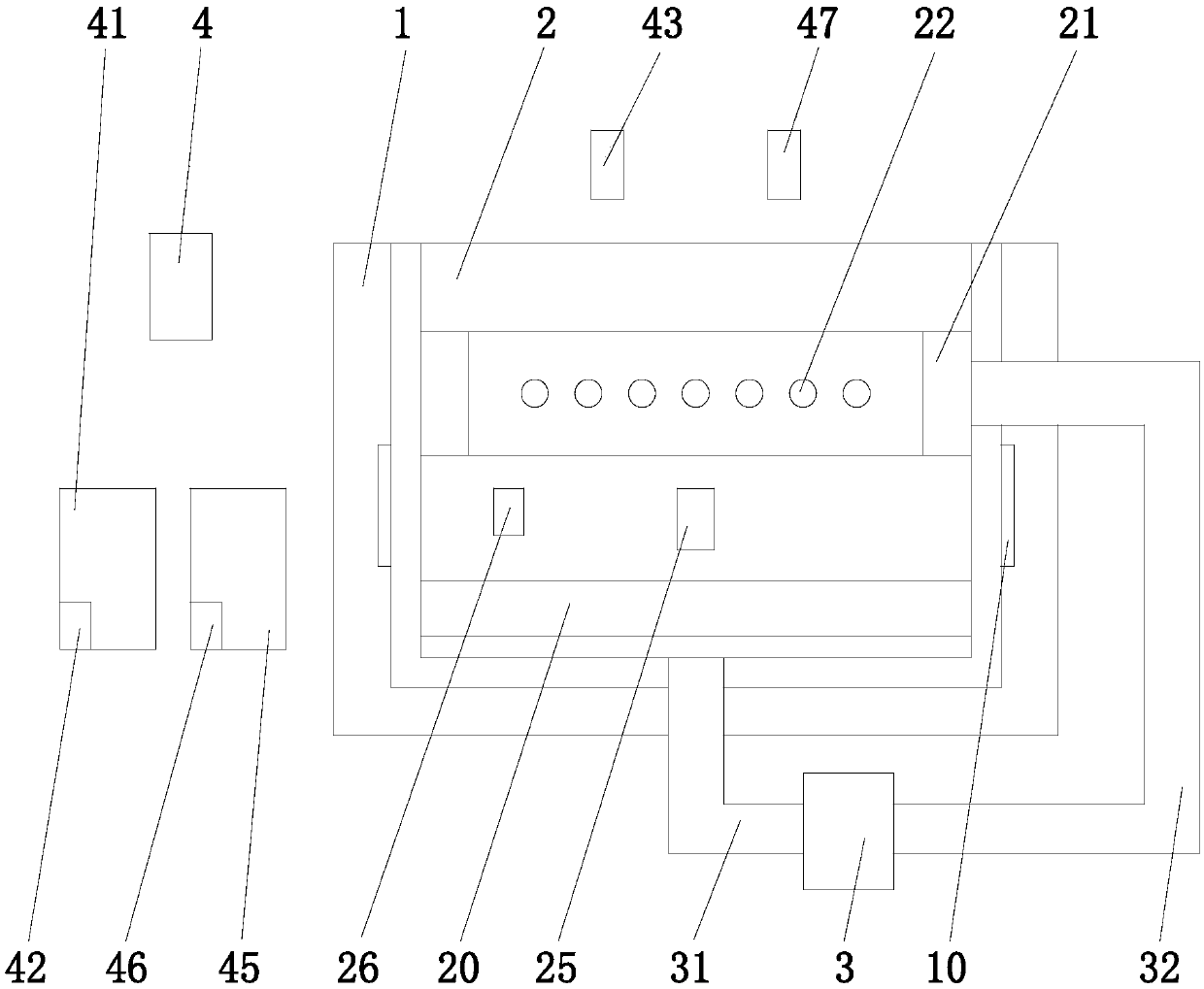

[0014] Refer to figure 1 , The present invention is a hot-dip galvanizing co-solvent tank with sufficient contact, including a heat preservation shell 1, a heating tank 2, a first circulation pipe 31, a second circulation pipe 32, an adsorption filter layer 20, a heating device 10, and a temperature sensor 25 , The first liquid pump 3, the control device 4, the heat preservation shell 1 is provided with a heating tank 2, and the heat preservation can be provided with a heating device 10 for heating the heating tank 2, and the heating tank 2 is provided with a temperature sensor 25. The temperature sensor 25 is located below the liquid level of the co-solvent. The heating tank 2 is provided with an adsorption filter layer 20 near the bottom, and the bottom of the heating tank 2 is provided with a first circulation pipe 31. The liquid inlet end of a first liquid pump 3 is connected, and the liquid outlet end of the first liquid pump 3 is connected with a second circulation pipe 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap