Buoy having tube part and method for manufacturing same

A technology of buoys and tubes, applied in the field of buoys and their manufacture, can solve the problems of low productivity, fragmentation, and negligible effect of marine pollution prevention, and achieve the effect of easy reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

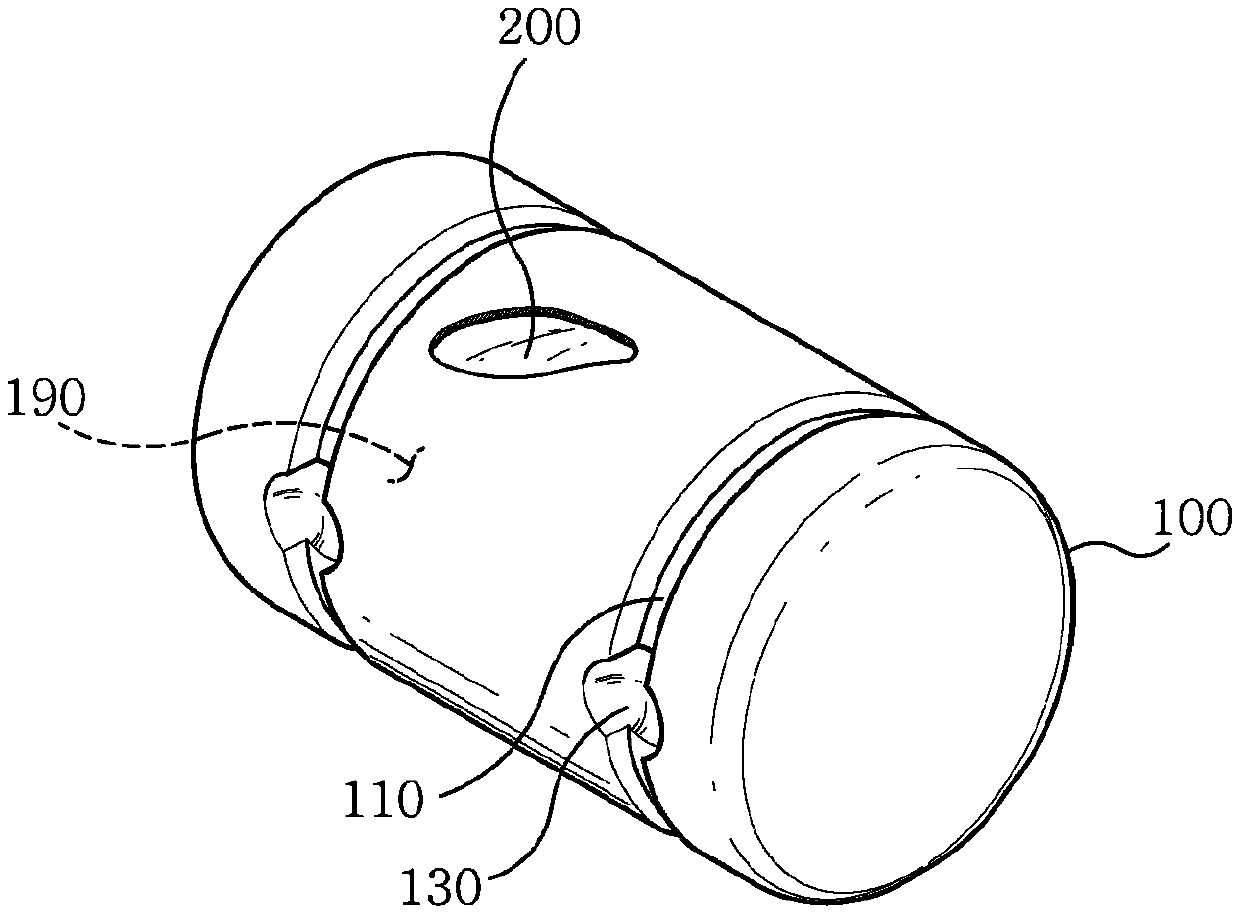

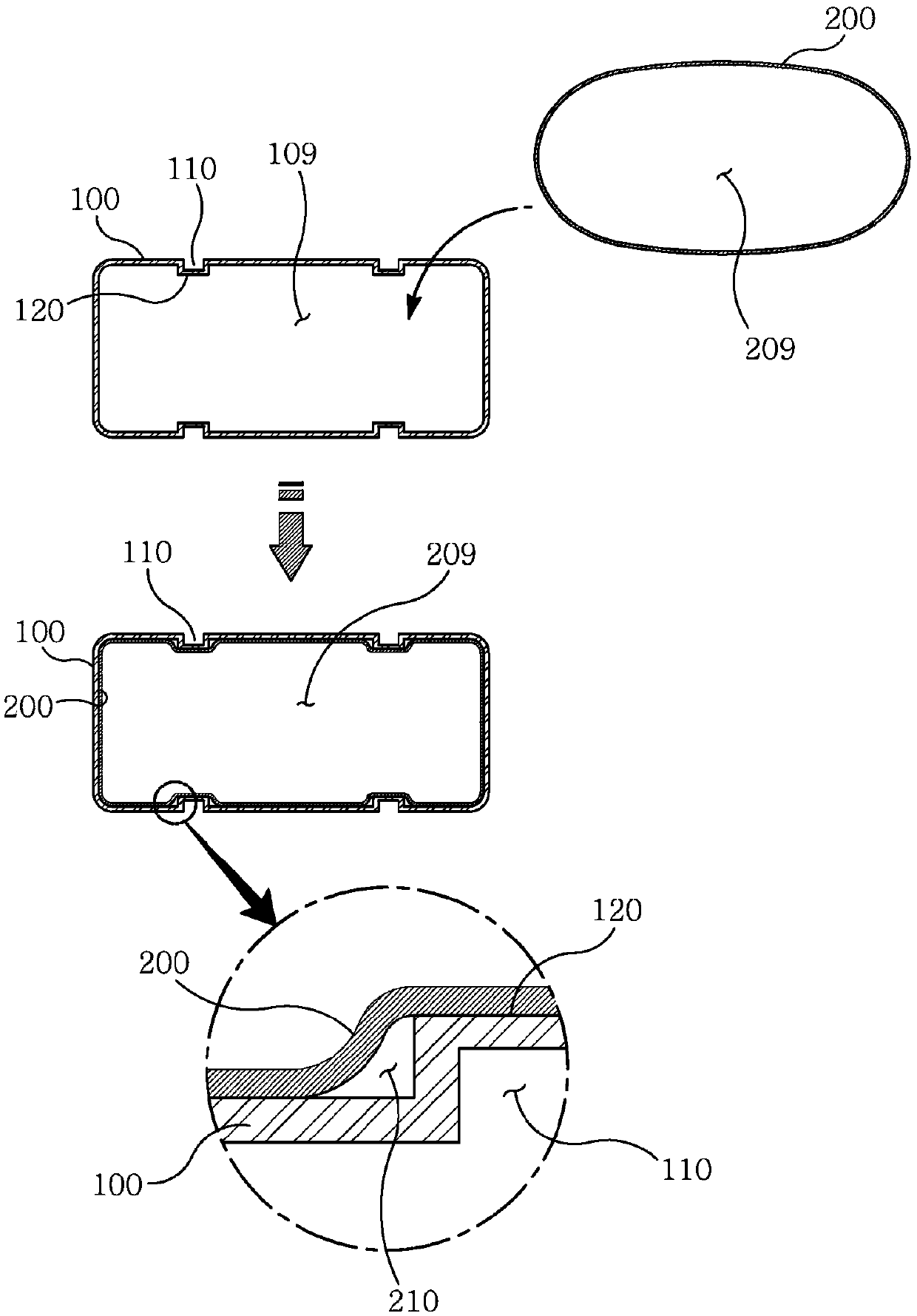

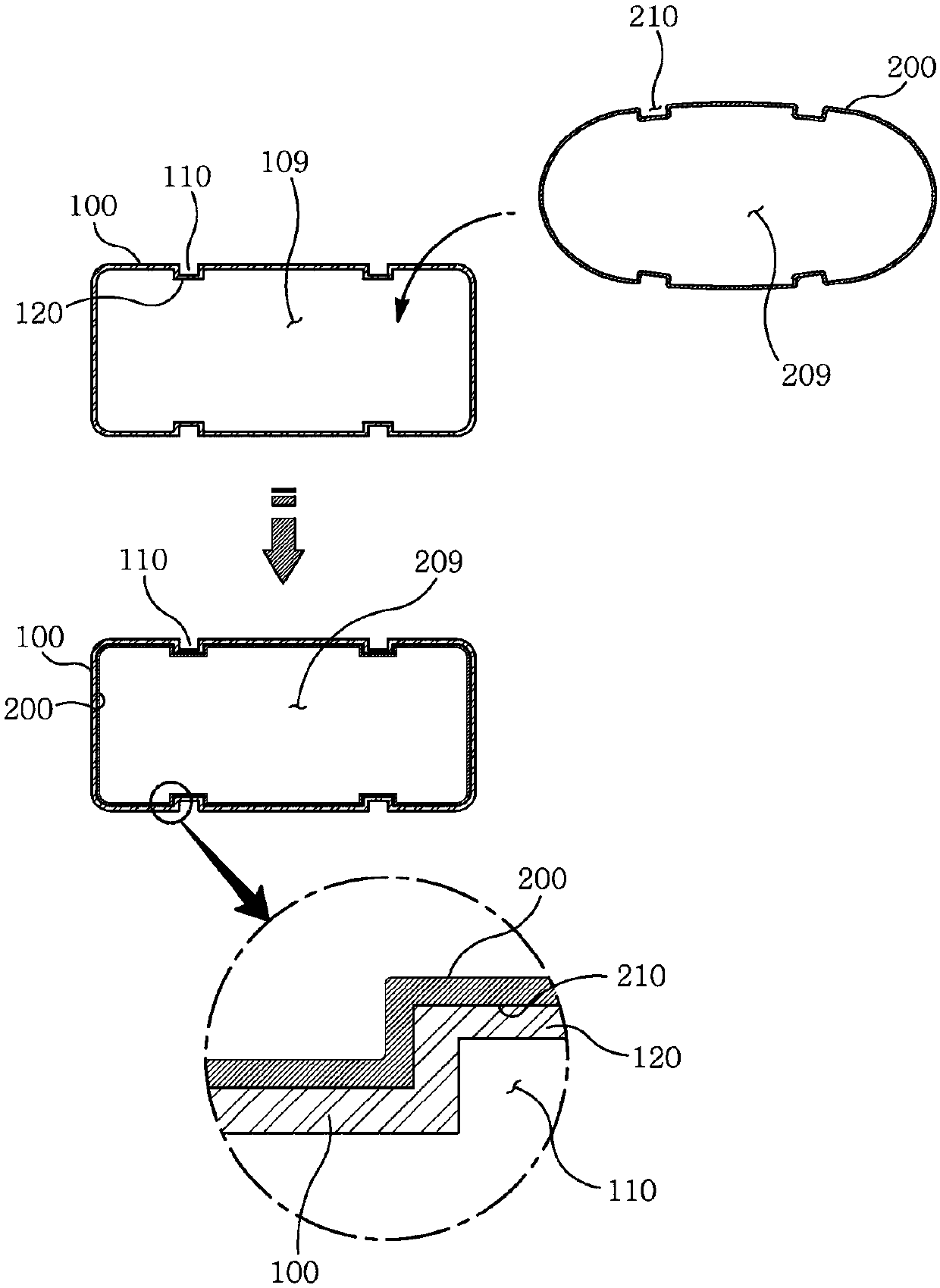

[0028] figure 1 It is a perspective view illustrating a buoy to which the present invention is applied. exist figure 1 In FIG. 2 , a state in which a part of the jacket portion 100 is cut away is shown in order to show the pipe portion 200 .

[0029] figure 1 The buoy shown in FIG. 2 can include an envelope part 100 and a tube part 200 .

[0030] The cuff part 100 can consist of a cylindrical shape with a central bore 109 sealed from the outside. As an example, the cuff portion 100 can be manufactured in a cylindrical shape, a spherical shape, or the like.

[0031] The cuff portion 100 with the sealed bore 109 can itself be buoyant. However, when manufacturing the buoy using only the envelope portion 100 , it is necessary to increase the thickness of the envelope portion 100 in order to avoid changes in the shape of the envelope portion 100 . In addition, because the envelope part 100 forms the shape of a buoy and is directly exposed to the external environment, it is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com