Method for operating an annealing furnace for annealing metal strip

A technology for metal strips and annealing furnaces, applied in furnaces, furnace types, furnace components, etc., and can solve problems such as the influence of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

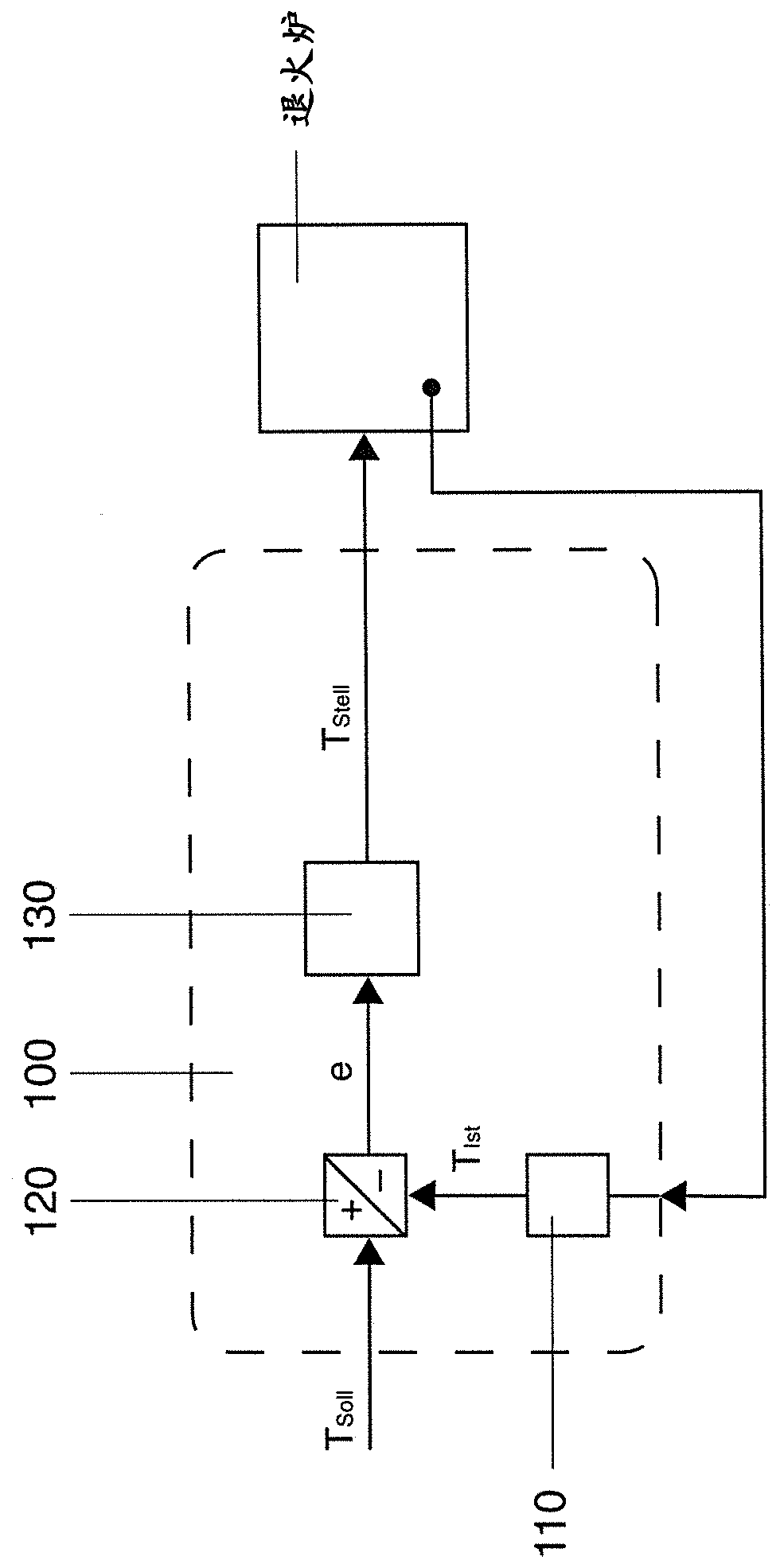

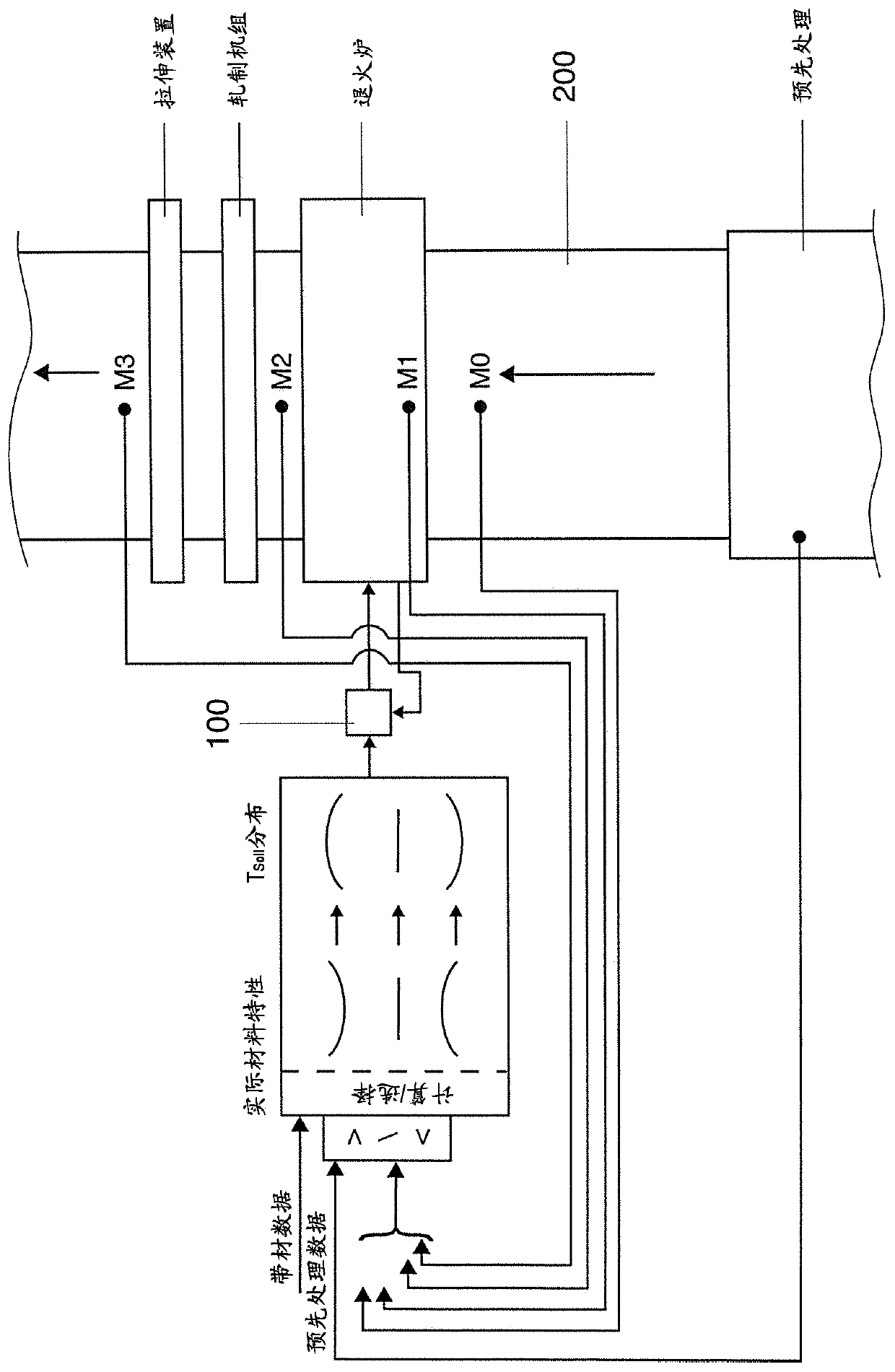

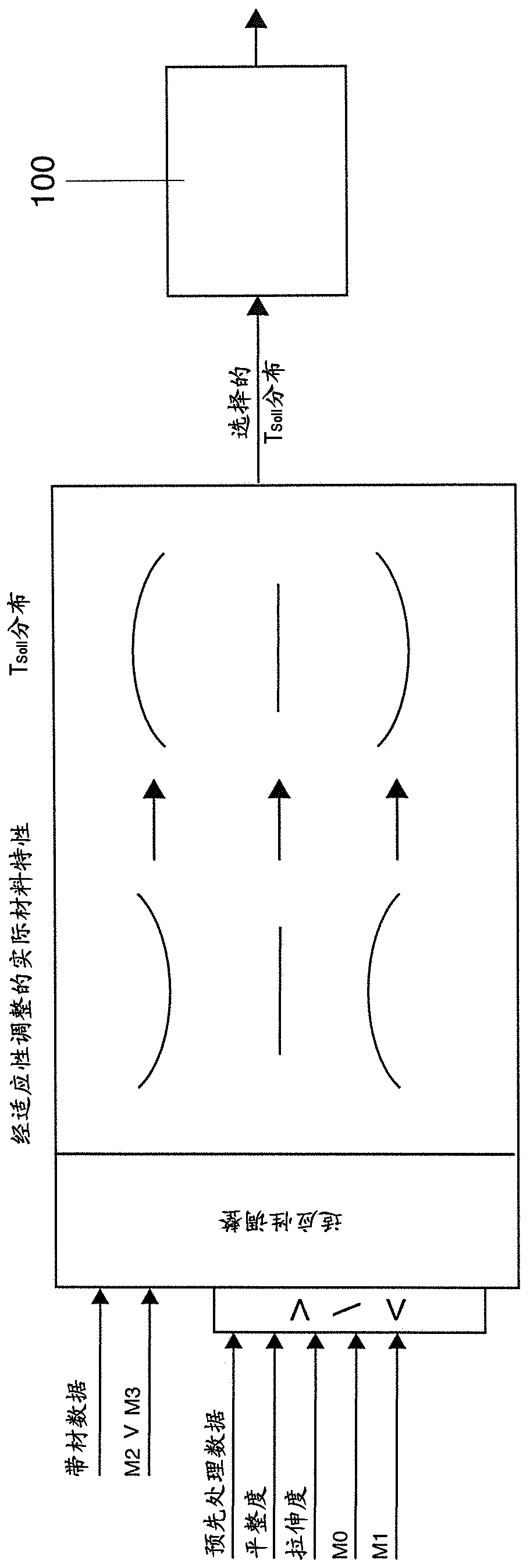

[0022] The invention is explained in detail below in the form of an embodiment with reference to the mentioned drawings. In all the figures, the capital letter T designates not only the individual temperature values but also the temperature distribution of the metal strip 200 (hereinafter also simply referred to as strip) over its length.

[0023] The control circuit comprises in particular a measuring device 110 for measuring the actual temperature distribution of the metal strip over its strip length, preferably in the annealing furnace. The actual temperature distribution resulting from the measurement T Ist In the comparison device 120 with the predetermined theoretical temperature distribution T of the metal strip 200 over its length Soll Compare. A possible control deviation e resulting from the comparison, or rather the formation of the difference, is supplied as an input variable to controller 130 . The controller 130 calculates a control signal T for the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com