Manual up-and-down type chalk cleaning blackboard

A blackboard and chalk technology, applied in the field of mechanical parts design, can solve the problems of polluting the environment and human health, occupying teaching time, and consuming a lot of time, so as to facilitate reprocessing or discarding, increase teaching time, and avoid injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

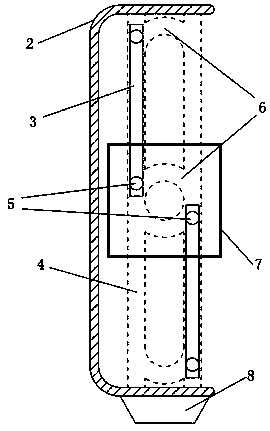

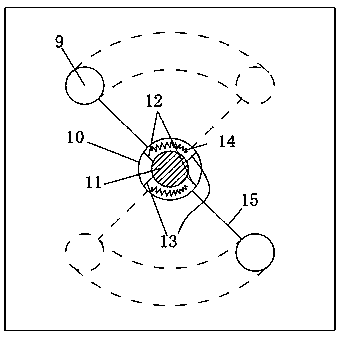

[0018] refer to Figure 1-3 The specific embodiment of the present invention adopts the following technical solutions: a manual ups and downs chalk cleaning blackboard, including a brush 1 fixed on the back of the blackboard, a blackboard bracket 2, a slide rail 3, a linear track 4, a spherical ball 5, a circular track 6, a position Transposition module 7, ash storage box 8, ball groove 9, cylinder 10, fixed shaft 11, baffle plate 12, limit plate 13, torsion spring 14, connecting rod 15. The linear track 4 communicates with the circular track 6 and is fixed on the blackboard bracket 2. The spherical ball 5 is located at the upper and lower ends of the side of the slide rail 3. The ash storage box 8 is fixed at the bottom of the blackboard bracket 2. The position transposition module 7 is located at the upper and lower sides. The junction of the blackboard is fixed at the middle position of the side of the blackboard bracket 2, the ball groove 9 is fixed on the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com