Quick charging pile

A fast-charging, out-of-the-box technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve problems such as cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

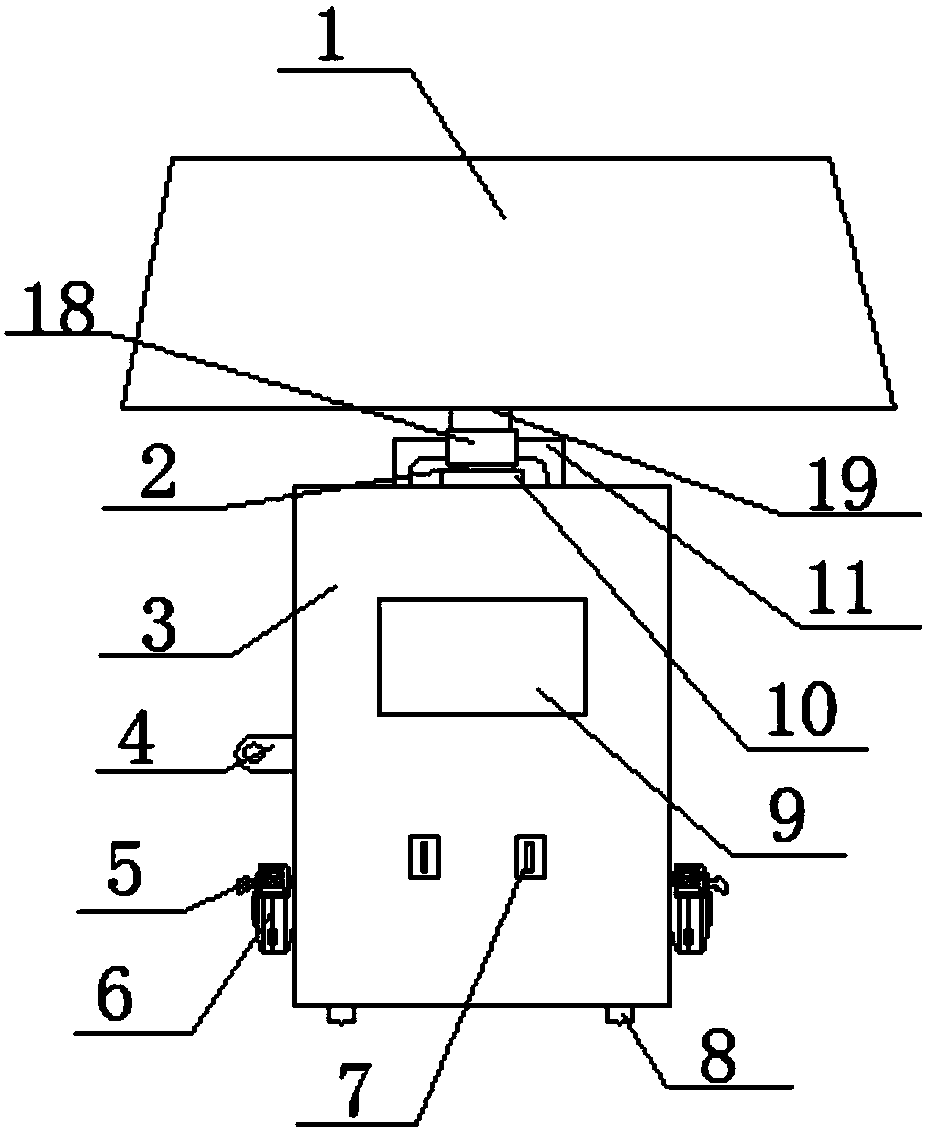

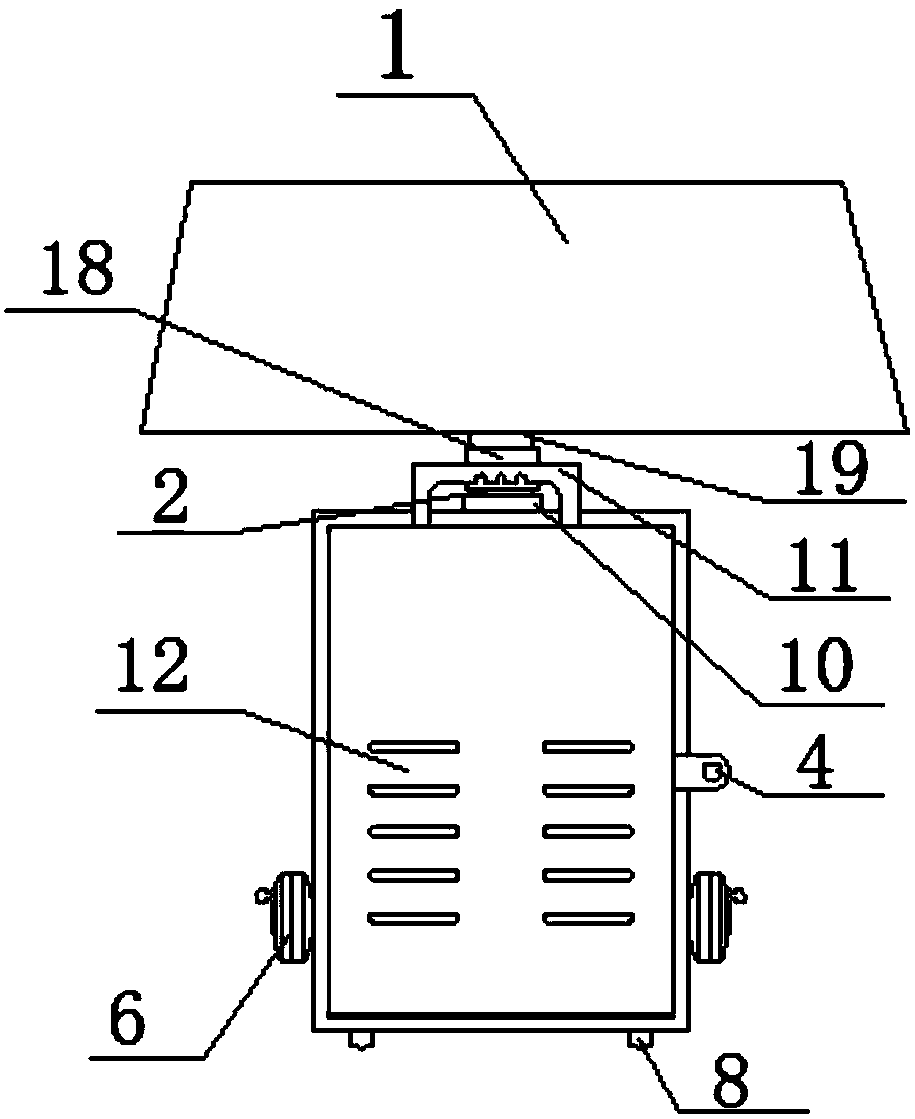

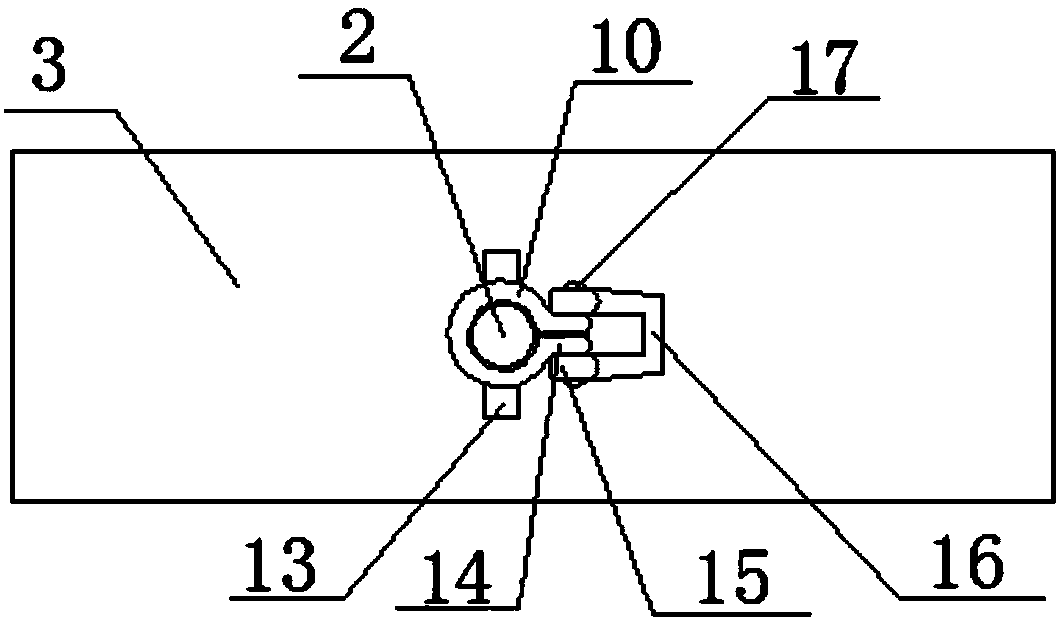

[0026] see Figure 1 to Figure 6 , the present invention provides a technical solution: the fast charging pile includes a ceiling 1, a cylinder 19 is fixed inside the ceiling 1, and a connecting column 18 is fixed to the bottom end of the column 19, the interior of the connecting column 18 is hollow, and the connecting column The inside of 18 is provided with the first thread, and the bottom end of connecting column 18 is provided with outer case 3 corresponding to the top of ceiling 1, and the top of outer case 3 is symmetrically fixed with connecting block 13, and the inner side of connecting block 13 is fixed with snap ring 10, The cross section of the snap ring 10 is C-shaped, and the opening of the snap ring 10 is symmetrically fixed with a block 14, and the outer side of the block 14 is provided with a limit block 15, and a bolt 17 runs through between the limit block 15 and the block 14 to limit The inner wall of the position block 15 is provided with a second screw thr...

Embodiment 2

[0028] see Figure 1 to Figure 8 , the present invention provides a technical solution: the fast charging pile includes a ceiling 1, a cylinder 19 is fixed inside the ceiling 1, and a connecting column 18 is fixed to the bottom end of the column 19, the interior of the connecting column 18 is hollow, and the connecting column The inside of 18 is provided with the first thread, and the bottom end of connecting column 18 is provided with outer case 3 corresponding to the top of ceiling 1, and the top of outer case 3 is symmetrically fixed with connecting block 13, and the inner side of connecting block 13 is fixed with snap ring 10, The cross section of the snap ring 10 is C-shaped, and the opening of the snap ring 10 is symmetrically fixed with a block 14, and the outer side of the block 14 is provided with a limit block 15, and a bolt 17 runs through between the limit block 15 and the block 14 to limit The inner wall of the position block 15 is provided with a second screw thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com