Cow leather thermal compounding type face sleeve and production process thereof

A composite, cowhide technology, applied in the direction of seat covers, layered products, lamination devices, etc., can solve the problems that the cover does not have the ability to absorb water, has discomfort, and the pants are wet, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

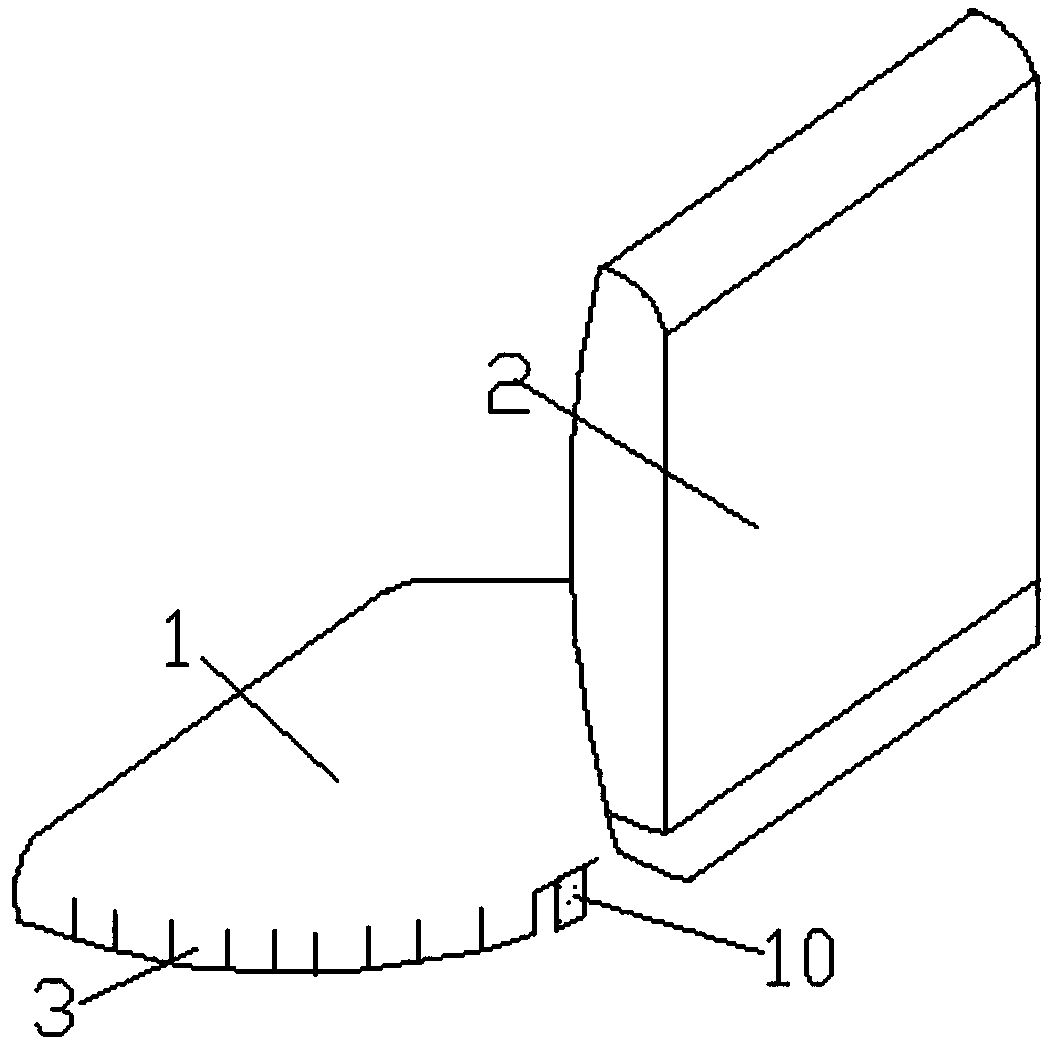

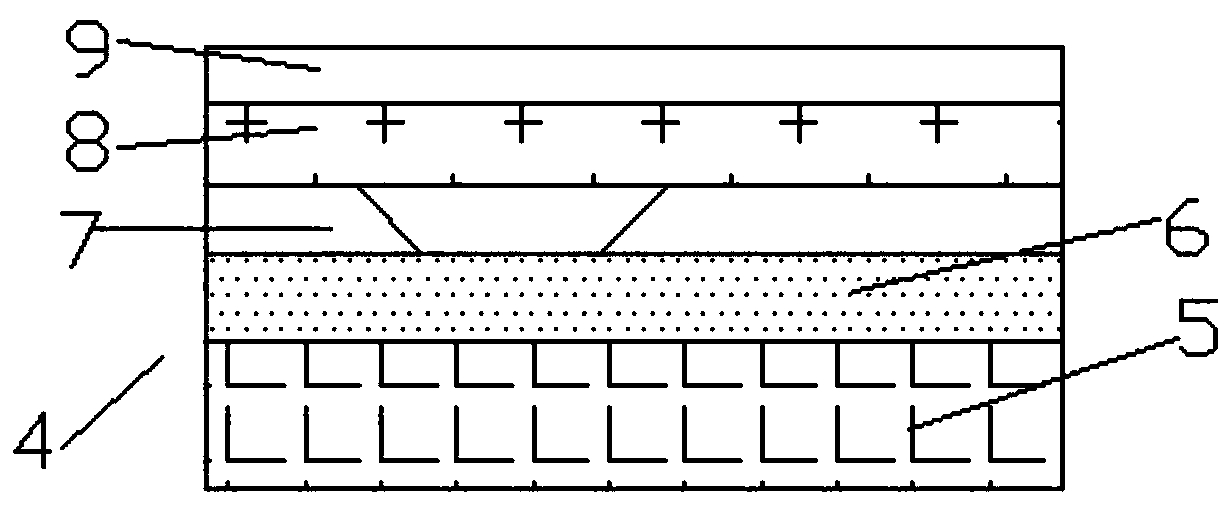

[0023] Such as Figure 1-2 As shown, a cowhide heat-composite face cover includes a seat cushion part 1 and a back part 2. The sides of the seat cushion part 1 and the back part 2 have constricted parts 3, and the seat cushion part 1 and the back part 2 are both It is made of cowhide heat-composite fabric 4, and the cowhide heat-composite fabric 4 includes a sponge layer 5, a first cowhide layer 6, a non-woven fabric layer 7, a water-absorbing layer 8 and a second cowhide layer 9 from inside to outside. Sitting on the car seat for a long time when the temperature is high, a large amount of sweat will be produced, and the sweat will be absorbed by the water-absorbing layer 8 along the second cowhide layer 9 to keep the second cowhide layer 9 dry, so that the person sitting feels comfortable. The non-woven fabric layer 7 has a waterproof effect, which can prevent the sweat absorbed by the water-absorbing layer 8 from entering the first cowhide layer 6 and the sponge layer 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com