Acid-treated attapulgite padding and preparation method thereof

A technology of attapulgite and acid treatment, applied in the poultry industry, poultry cages or houses, animal husbandry, etc., can solve the problems of poor water absorption and deodorization performance of cat litter, and achieve low cost, prolonged use time, and increased specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] One of the preparation methods of embodiment 1 acid treatment attapulgite pad

[0037] The acid-treated attapulgite litter is prepared from the following raw materials in parts by weight: 400 parts of acid-treated attapulgite, 25 parts of corn starch, 3 parts of potassium sorbate, and 200 parts of water.

[0038] The acid-treated attapulgite gasket comprises the following steps:

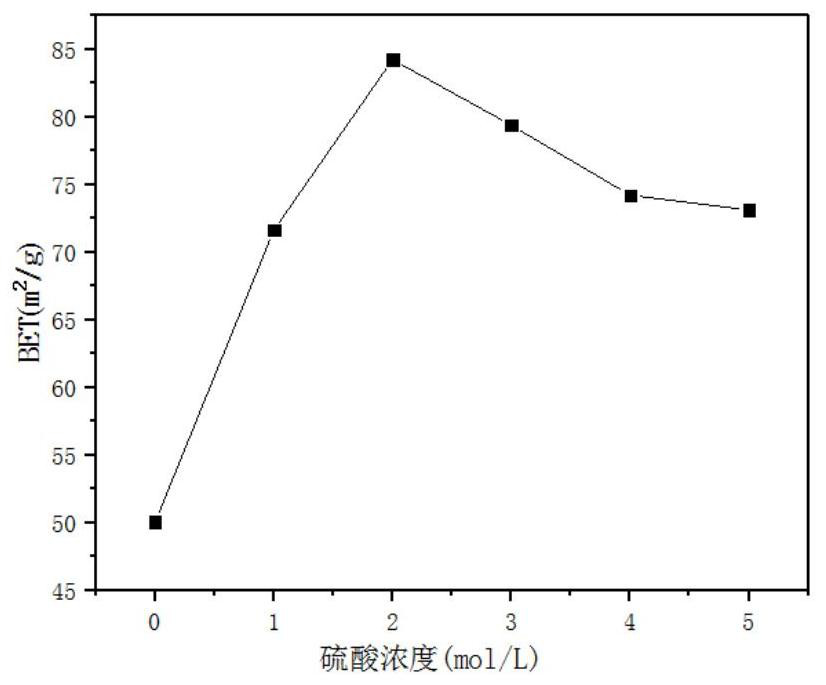

[0039] (1) Pulverize the attapulgite and pass through a 200 mesh sieve, then modify it with 2mol / L industrial sulfuric acid, the solid-liquid ratio is 1:10, stir the mixed solution on a magnetic stirrer for half an hour, and let it stand at room temperature Set aside for 24 hours, add distilled water to wash to remove excess sulfuric acid, filter with a vacuum pump, dry in a blast drying oven, then continue to crush and pass through a 200-mesh sieve, and store for future use.

[0040] (2) Weigh 400 parts of acid-treated attapulgite and 3 parts of potassium sorbate, and mix them uniformly.

...

Embodiment 2

[0044] One of the preparation methods of embodiment 2 acid treatment attapulgite pad

[0045] The acid-treated attapulgite litter is prepared from the following raw materials in parts by weight: 400 parts of acid-treated attapulgite, 20 parts of tapioca starch, 3 parts of potassium sorbate, and 200 parts of water.

[0046] The acid-treated attapulgite gasket comprises the following steps:

[0047] (1) Pulverize the attapulgite and pass through a 200 mesh sieve, then modify it with 2mol / L industrial sulfuric acid, the solid-liquid ratio is 1:10, stir the mixed solution on a magnetic stirrer for half an hour, and let it stand at room temperature Set aside for 24 hours, add distilled water to wash to remove excess sulfuric acid, filter with a vacuum pump, dry in a blast drying oven, then continue to crush and pass through a 200-mesh sieve, and store for future use.

[0048] (2) Weigh 400 parts of acid-treated attapulgite and 3 parts of potassium sorbate, and mix them uniformly. ...

Embodiment 3

[0056] Example 3 Key Index Evaluation Method of Acid Treatment Attapulgite Pad

[0057] Evaluation method of sensory indicators: Place the litter sample in a white tray, in an environment without direct sunlight, sufficient light, and no peculiar smell, check the color, mildew and impurities with eyes, and check the smell with nose.

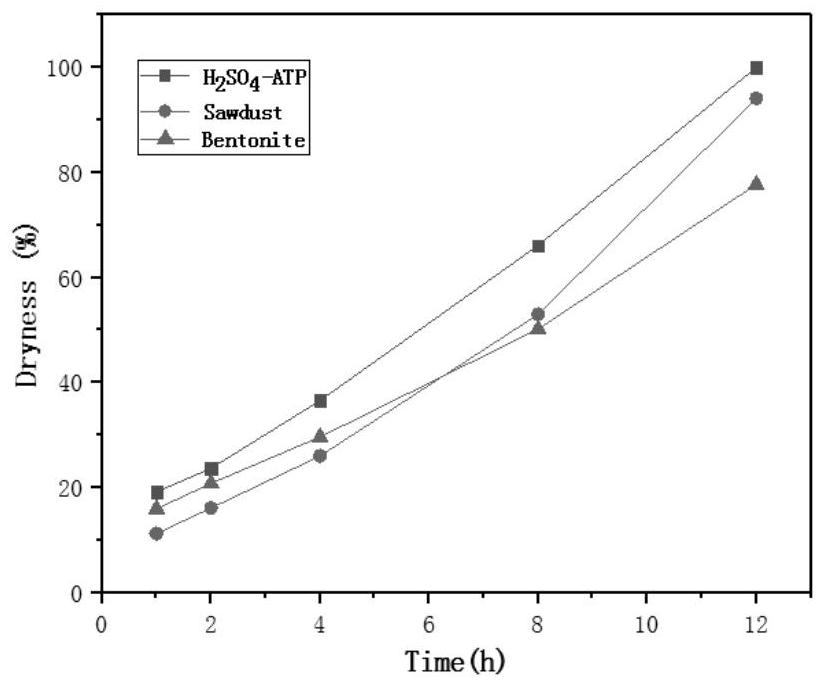

[0058] figure 2 It is acid-treated attapulgite litter. It can be seen from the figure that the litter has uniform color, no obvious color difference, and no foreign impurities visible to the naked eye. The detection of its smell with the method of sniffing, finds that this litter has no irritating smell, also has no moldy smell.

[0059] Table 1 shows the EDS elemental analysis results of the attapulgite, and Table 2 shows the EDS elemental analysis results of the acid-treated attapulgite. From the data in the table, after the attapulgite is treated with 2mol / L industrial sulfuric acid, the contents of Mg, Al, K, Ca, and Fe decrease, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com