Water absorbing tray and preparing method thereof

A tray and water-absorbing layer technology, applied in the field of food packaging, can solve the problems of easy sticking on the surface of fresh products, inconvenient use, etc., and achieve the effects of extending storage time, convenient use, and enhancing water-absorbing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] This embodiment also provides a method for preparing a water-absorbing tray, which includes the following steps:

[0041] Put the dry raw materials into the continuous extrusion foaming equipment, heat and melt, then add foaming agent and mix evenly, and foam to prepare foamed sheet;

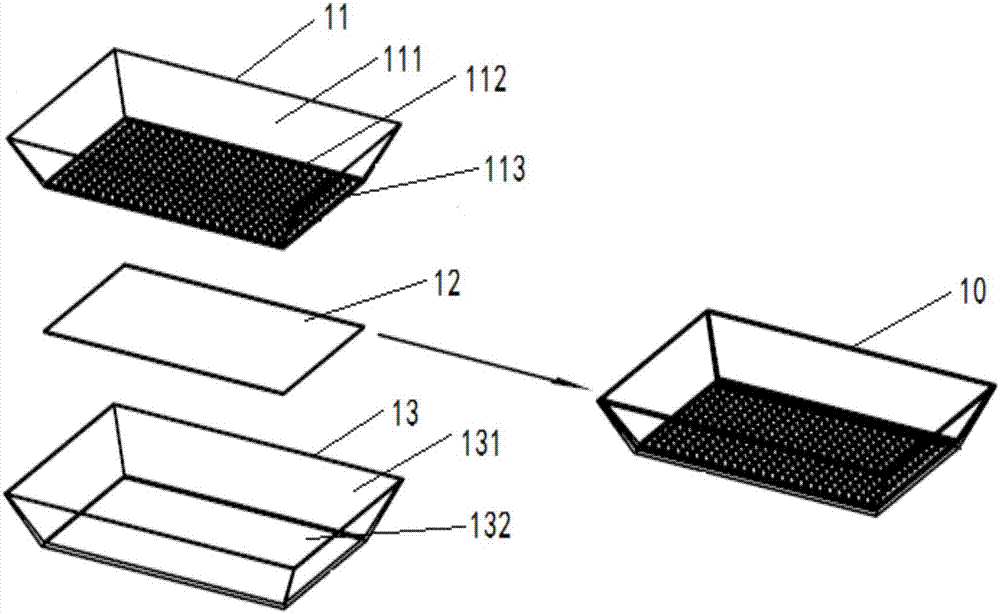

[0042]The above-mentioned foamed sheet is passed through a blister machine to prepare an inner tray body and an outer tray body, both of which include a chassis and a side wall, and the chassis and the side wall cooperate to form a cavity structure with an opening at the top;

[0043] Forming a plurality of holes through the chassis on the chassis of the inner pan body;

[0044] A layer of water-absorbing material is evenly spread on the upper surface of the chassis of the outer disc body to form a water-absorbing layer, and the inner disc body is bonded to the outer disc body through heat sealing technology.

[0045] Specifically, in one embodiment, the blowing agent is carbon dioxide o...

Embodiment 1

[0049] Add the dry polylactic acid 4032D to the continuous extrusion foaming equipment, heat and melt, then add the foaming agent butane and mix evenly, and respectively prepare open foams with a foaming ratio of 25 times, an opening ratio of 80%, and a thickness of 3mm. A foamed sheet with a cellular foam structure, and a foamed sheet with a foaming ratio of 10 times, a closed rate of 75%, and a thickness of 2 mm with a closed-cell foamed sheet;

[0050] The above-mentioned foamed sheet is made into an outer tray body and an inner tray body respectively through a blister machine, the inner tray body and the outer tray body both include a chassis and a side wall, and the chassis and the side wall cooperate to form a cavity structure with an opening at the top;

[0051] 300 holes are designed on the chassis of the inner plate, the hole diameter is 1mm, and the hole depth is 3.1mm;

[0052] Sprinkle 5g of BLD-70A water-absorbing resin evenly on the upper surface of the chassis o...

Embodiment 2

[0054] Add dry polylactic acid 190 to supercritical continuous extrusion foaming equipment, heat and melt, and then add foaming agent carbon dioxide to prepare open cells with a foaming ratio of 20 times, an opening ratio of 70%, and a thickness of 2mm. A foamed sheet with a foamed structure, and a foamed sheet with a closed-cell foamed structure with a foaming ratio of 8 times, a closed rate of 90%, and a thickness of 1.5 mm;

[0055] The above-mentioned foamed sheet is made into an outer tray body and an inner tray body respectively through a blister machine, the inner tray body and the outer tray body both include a chassis and a side wall, and the chassis and the side wall cooperate to form a cavity structure with an opening at the top;

[0056] 400 holes are designed on the chassis of the inner tray, the hole diameter is 0.07mm, and the hole depth is 2.2mm;

[0057] Sprinkle 7g of sodium carboxymethylcellulose powder evenly on the upper surface of the chassis of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com