Ultra-high-pressure pressure relief pump

A pressure relief pump and ultra-high pressure technology, which is applied in the field of pressure relief pumps, can solve the problems of harsh pressure relief components and large oil pressure variation range, and achieve the effects of fast pressure relief, slow pressure relief, and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

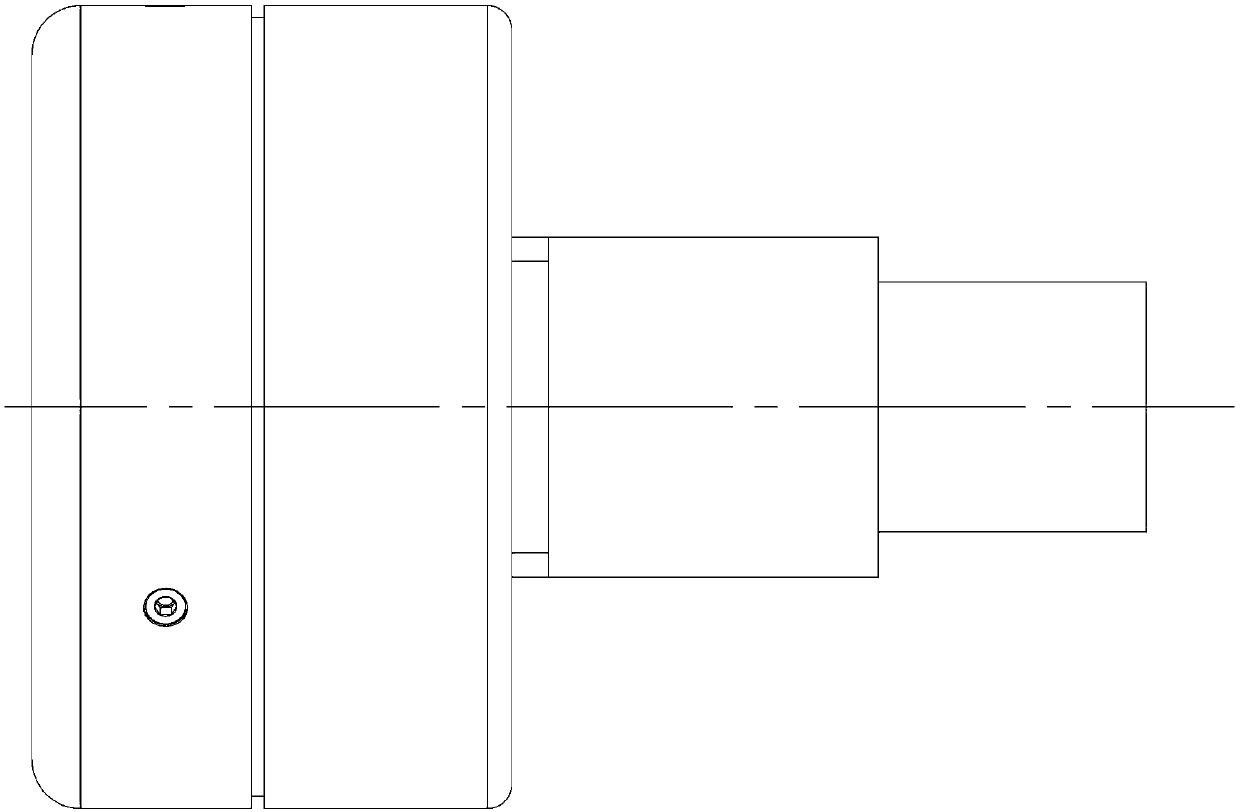

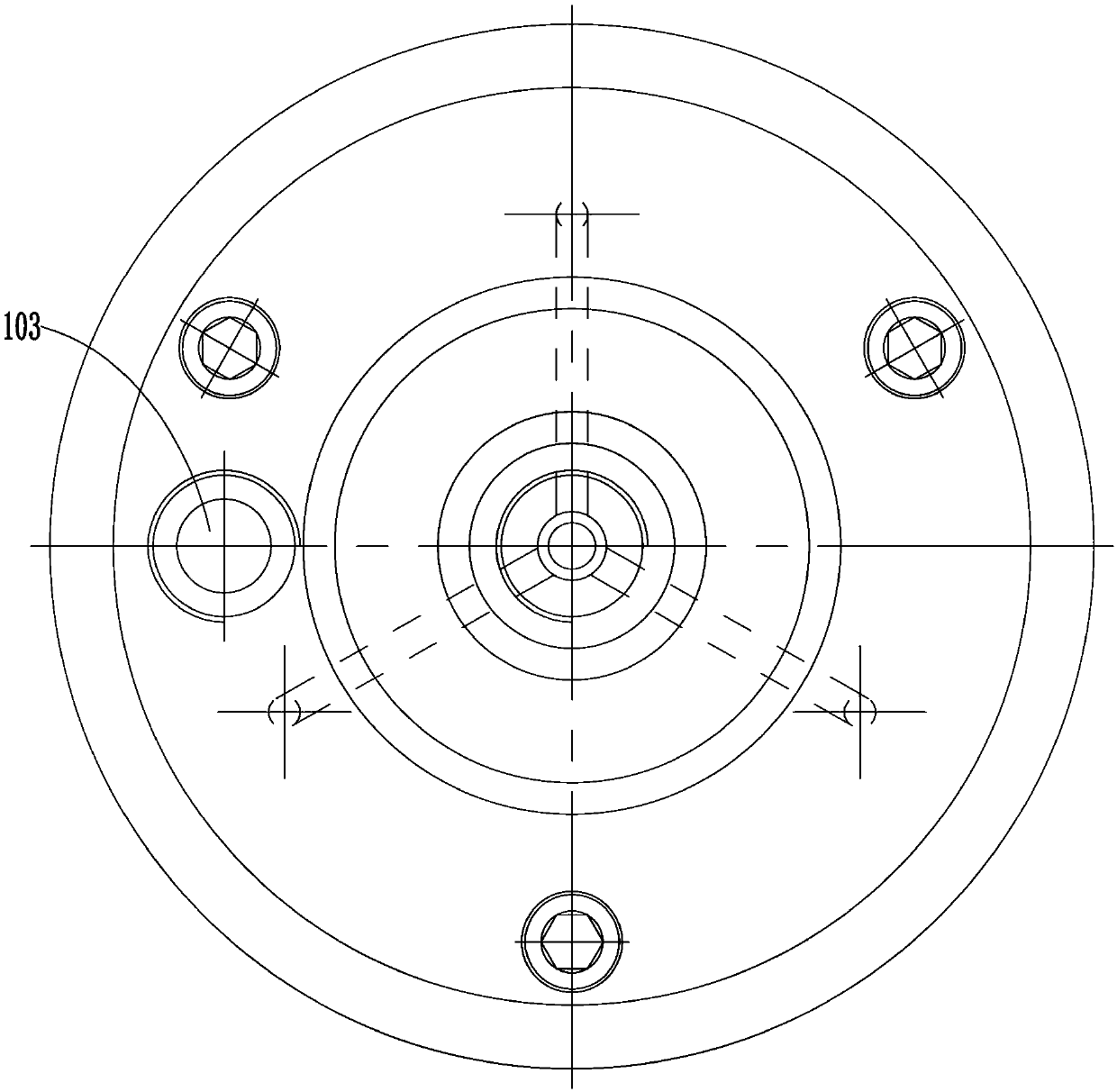

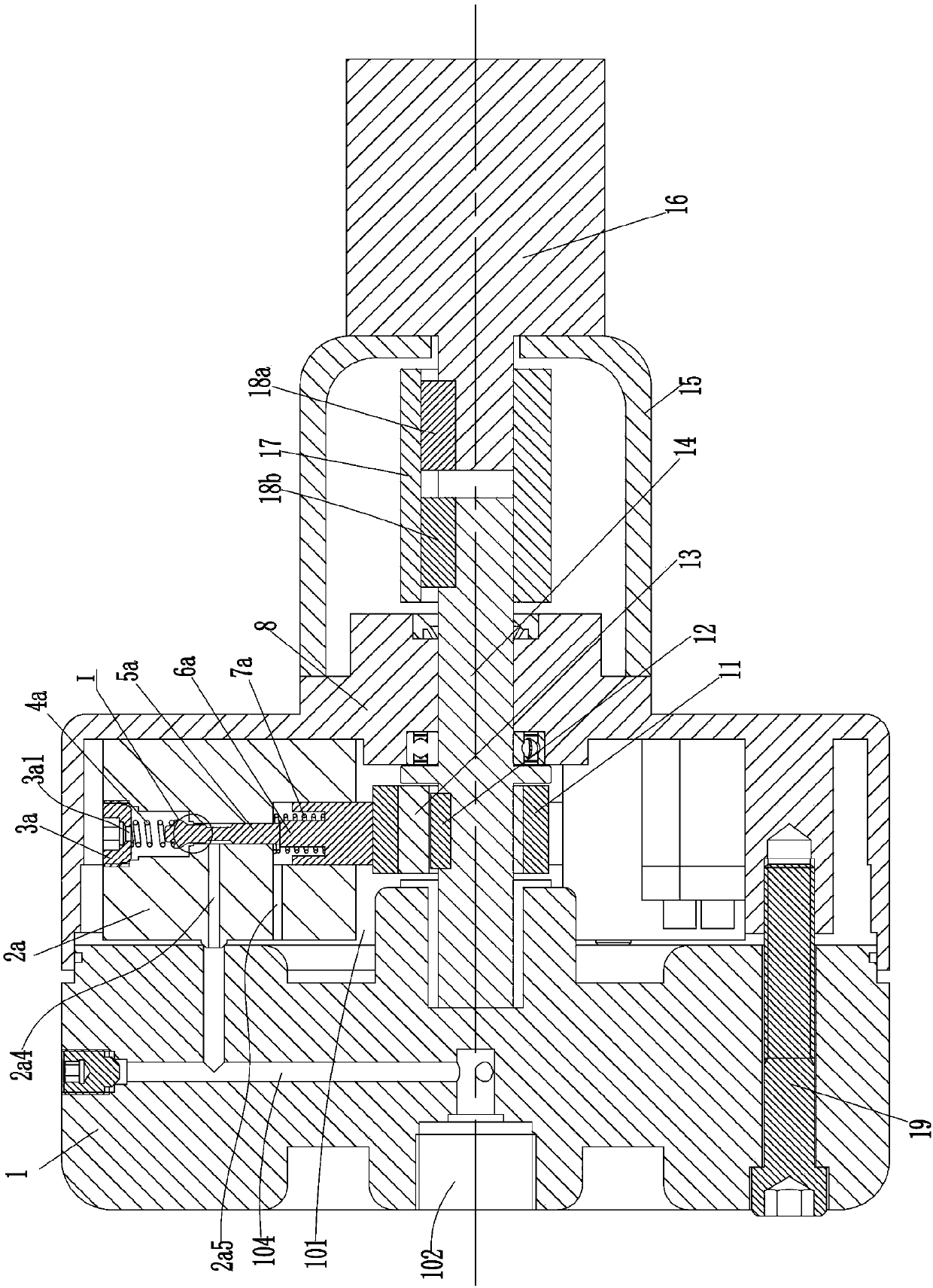

[0028] see Figure 1-8 As shown, an ultra-high pressure relief pump includes a pump body 1, and a pump casing 8 installed on the right end surface of the pump body 1 through bolts 19, and an oil discharge is formed between the pump casing 8 and the right end surface of the pump body 1. Chamber 101; the right end surface of the pump body 1 is rotatably connected with a rotating shaft 14 protruding from the pump casing 8, and three pressure relief chambers are evenly installed on the right end surface of the pump body 1 in the oil drain chamber 101 with the rotating shaft 14 as the center. Module 3, the first shaft sleeve 13 is installed eccentrically on the rotating shaft 14 through the first pin key 12 in the oil drain chamber 101, and the second shaft sleeve 13 with a regular hexagonal cross section is rotatably connected to the first shaft sleeve 13. Shaft sleeve 11.

[0029] The pressure relief module 3 includes a pressure relief cylinder 2a, a pressure relief valve core 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap