Mechanical connecting part

A connector and mechanical technology, which is applied in the direction of connecting components, shrinkage connections, mechanical equipment, etc., can solve problems such as connector falling off, and achieve the effect of overcoming the falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention discloses a mechanical connector. The specific implementation manner of the present invention will be further described below in combination with preferred embodiments.

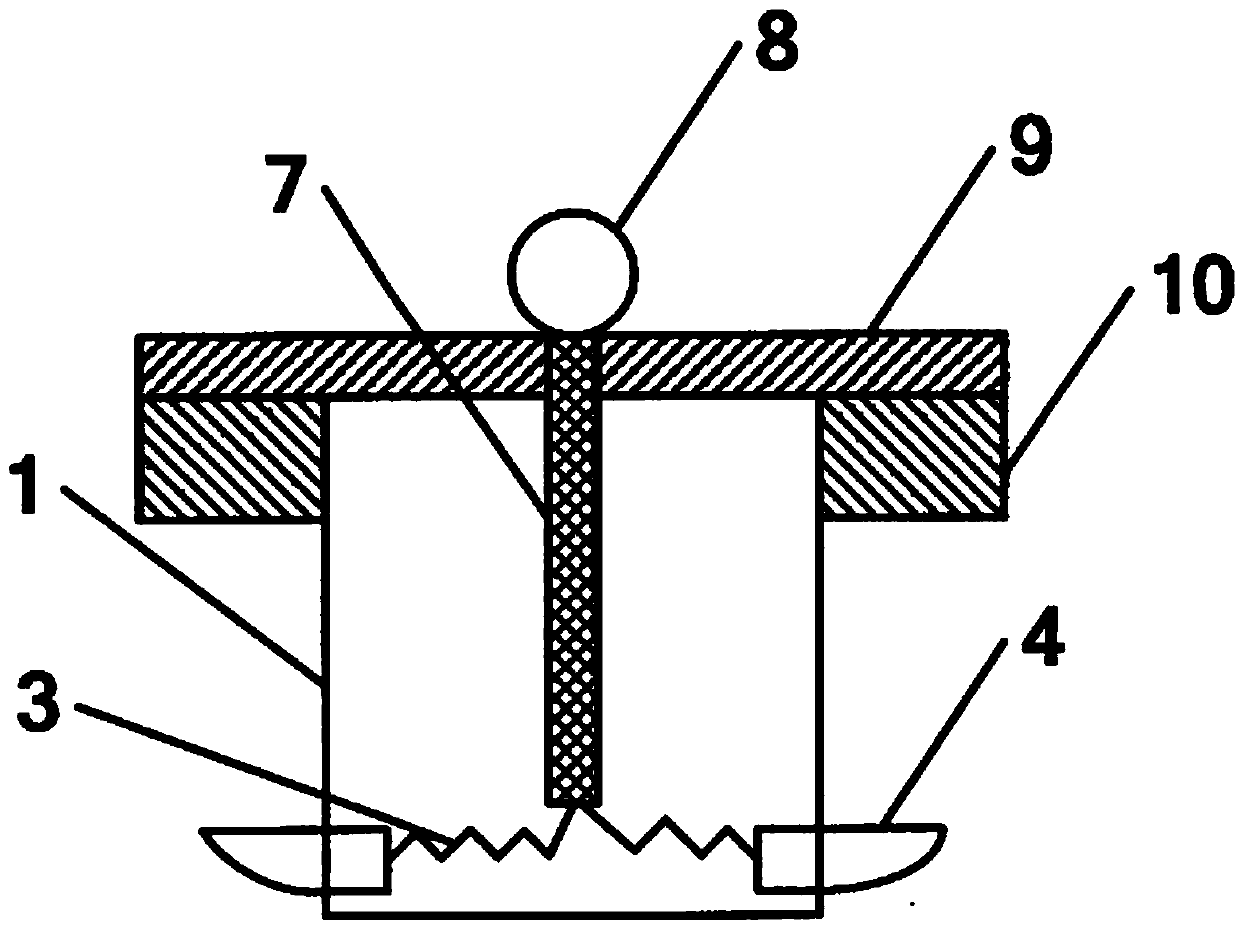

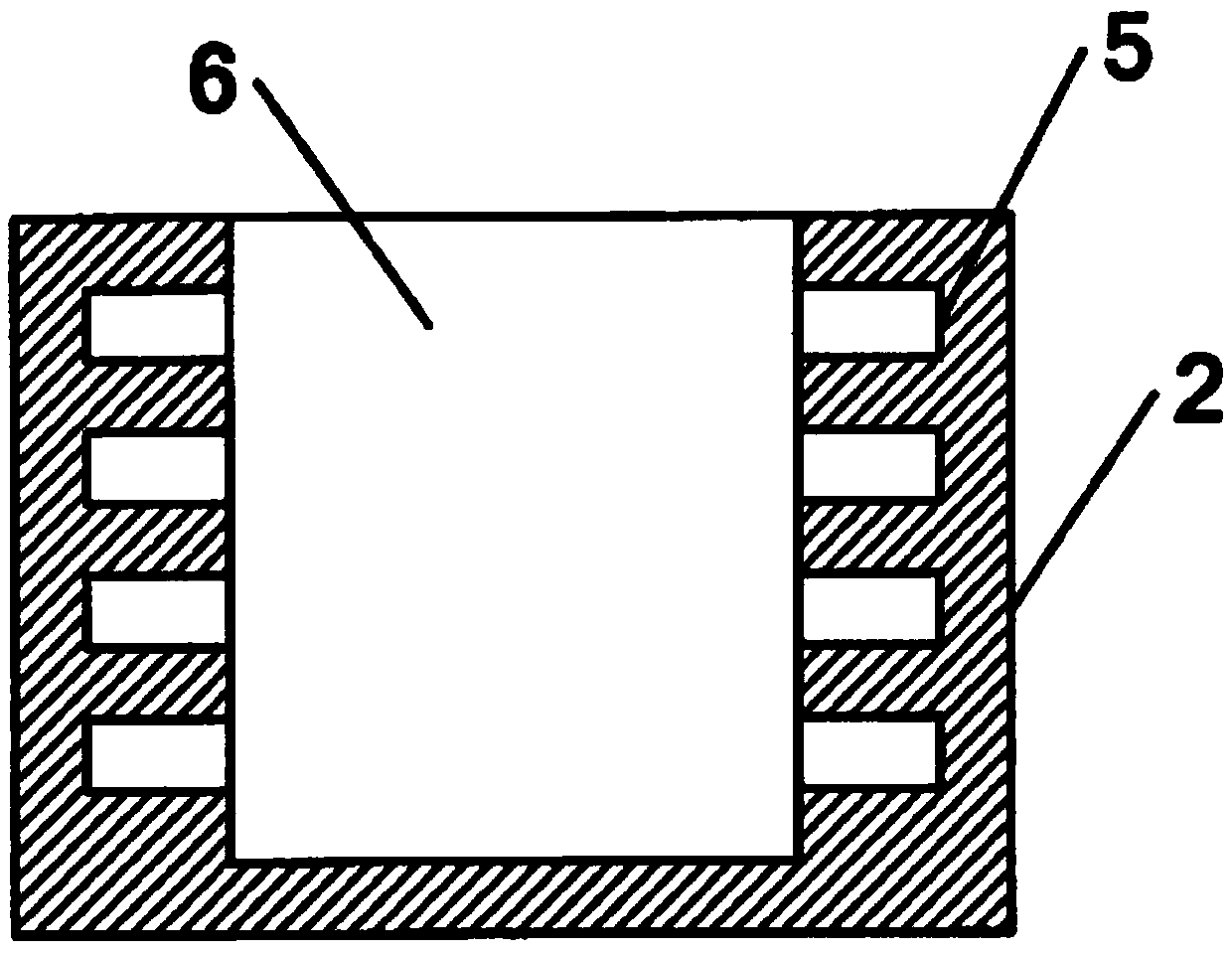

[0012] see attached figure 1 and figure 2 , figure 1 and figure 2 The structure of the present invention is shown. The mechanical connector includes a button cap 1 and a button body 2. The inside of the button cap 1 is set as a hollow structure and the bottom of the button cap 1 is provided with an opening. The opening There is a card and part 4 embedded in the place, the front end of the card and part 4 passes through the opening, and the rear end of the card and part 4 is located inside the buckle cap 1 and connected with the spring 3; the buckle body 2 is provided with the buckle cap 1. A cavity 6 with a suitable shape, with several snap rings 5 extending outward on both sides of the cavity 6; the depth of the snap rings 5 is consistent with the length of the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com