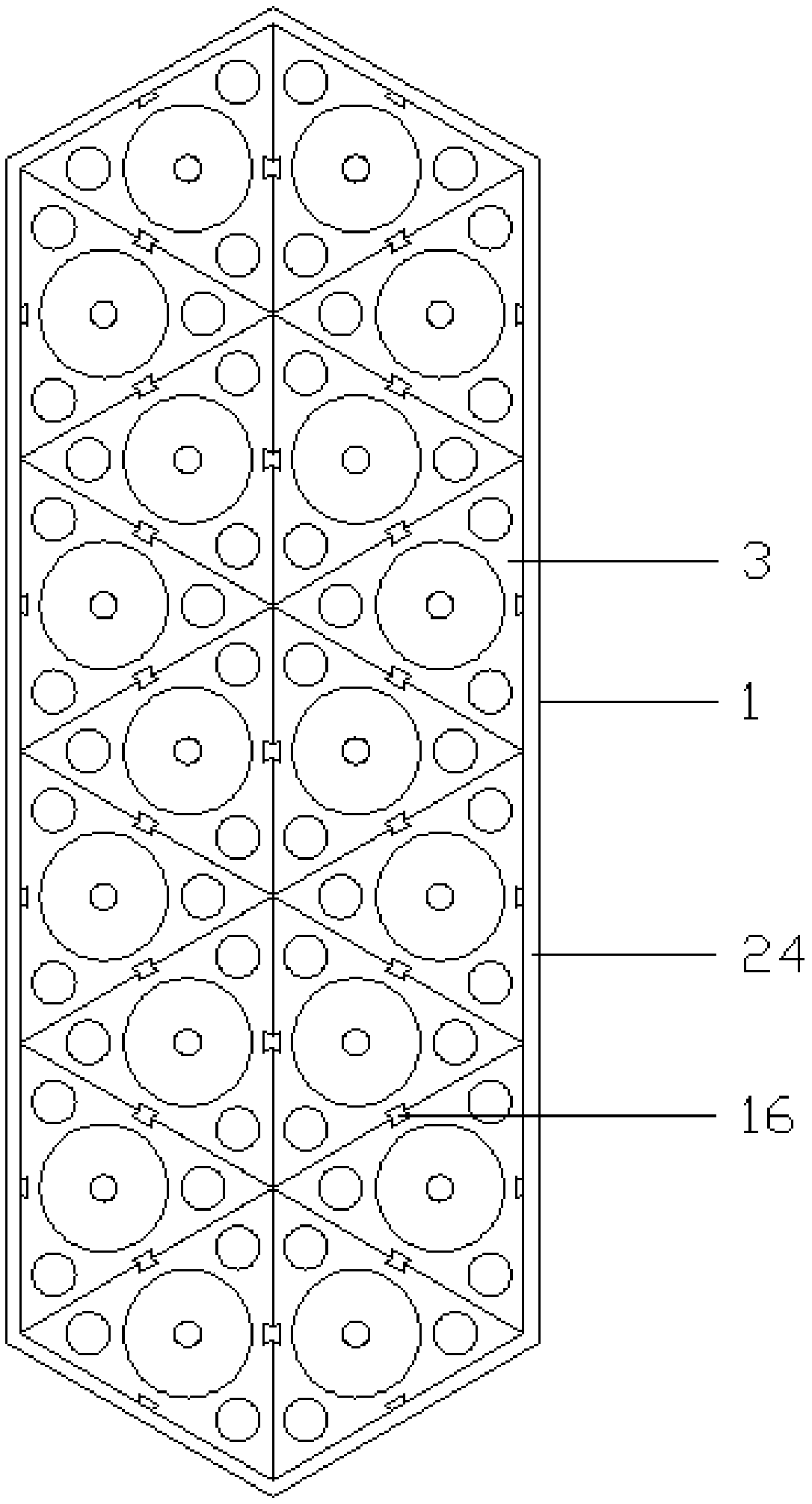

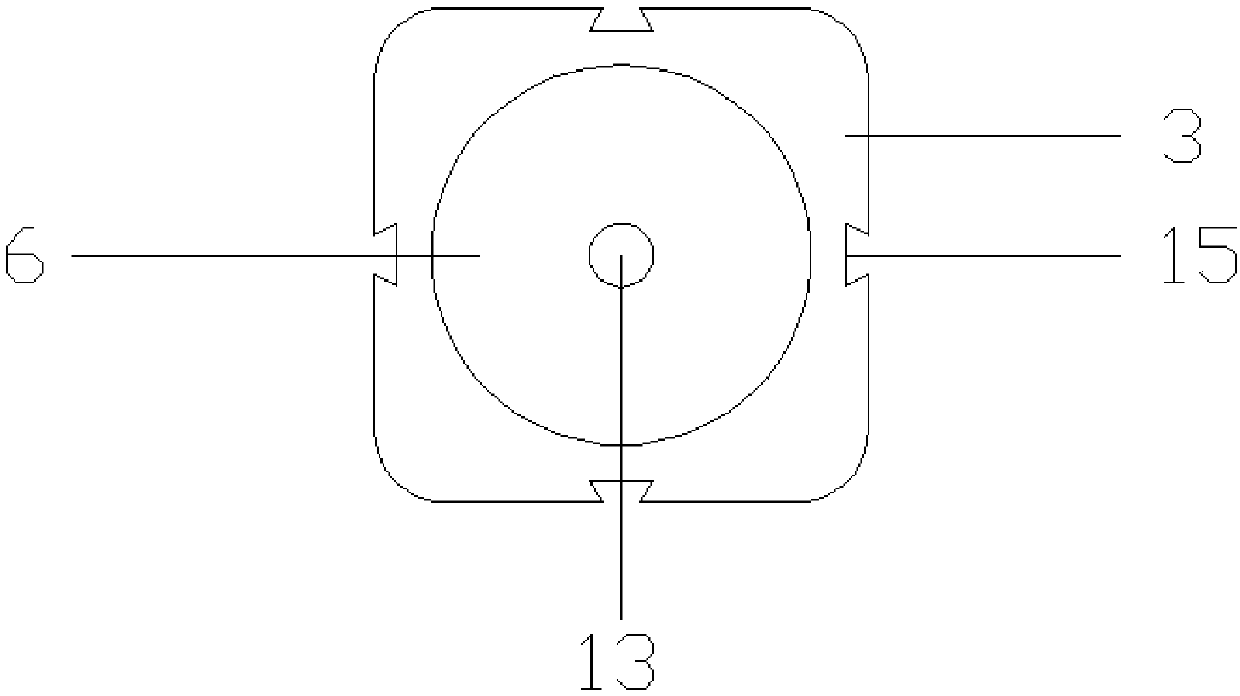

Image-text fireworks dot matrix emitter and forming mold used for manufacturing dot matrix emitter

A technology for forming molds and projectiles, which is applied to fireworks, weapon types, offensive equipment, etc., can solve problems such as high cost, high cost, and large volume, and achieve the effect of reducing production costs, improving production efficiency, and simple mold structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

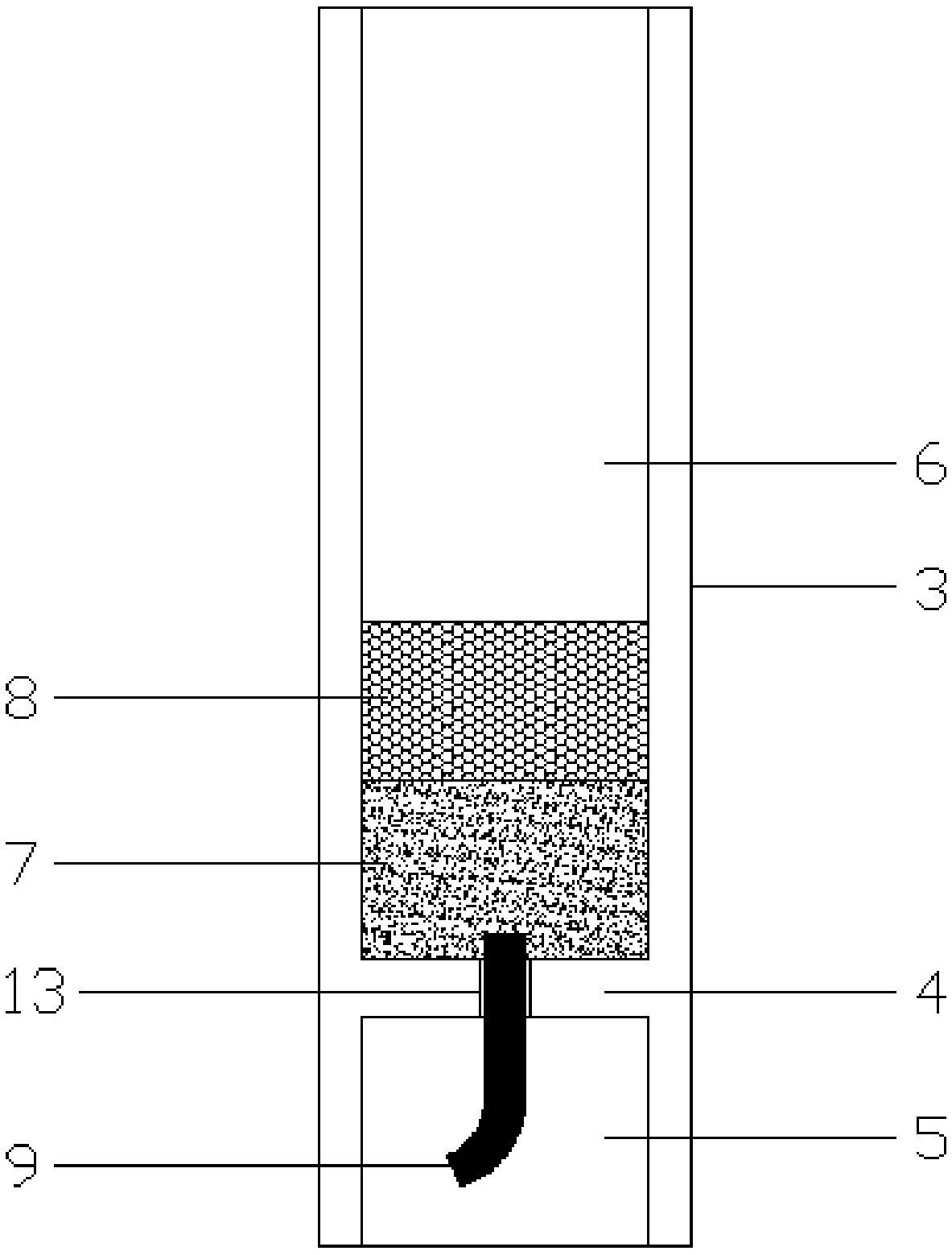

[0054] Before actual use, set up the molding mold on the injection machine, then inject the engineering plastics heated and melted on the injection machine into the mold cavity through the feed port, and after cooling, open the upper and lower templates to make the molded ejection The cylinder is wrapped on the launch forming column on one side of the lower membrane plate, and then the top plate is pushed to push the connected push plate through the push rod, and the launch tube wrapped on the launch forming column is pushed out of the forming mold, thereby obtaining the gunpowder-filled launch tube.

[0055] Put the lead wire in the ignition compartment of the launch tube, insert one end of the lead wire into the launch compartment, then add the fireworks propellant and the fireworks display charge in turn into the launch compartment, and seal the mouth of the launch compartment with a plastic film; Wherein, the color adopted by the sealed plastic film is consistent with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com