An all-round measurement device for bearing noise of a double-axis coil motor

A technology of motor bearing and measuring device, applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of increased vibration and noise, inaccurate test results, endangering the safety of motors, etc., to improve accuracy performance, satisfy multi-dimensional testing, and improve test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

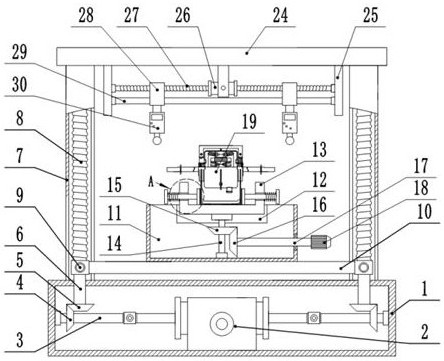

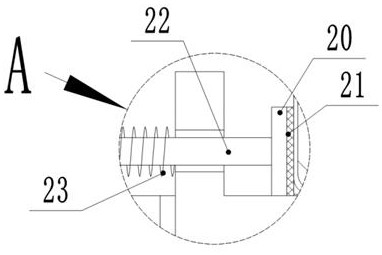

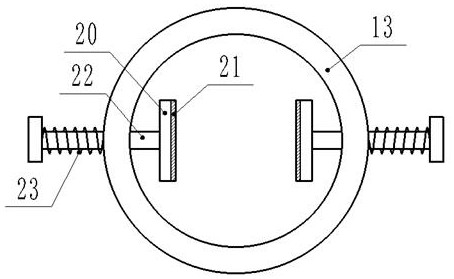

[0021] see Figure 1-3 , a dual-axis coil motor bearing noise omnidirectional measuring device, including a base 1, a slider 9, a lifting frame 10, a main workbench 11, a drive motor 26 and a noise decibel meter 30, the base 1 is a hollow structure inside, The inner center of the base 1 is fixedly installed with a biaxial motor 2 through a bracket. The other end of the first driving bevel gear 4 is fixedly installed on the inner walls of both sides of the base 1 through bearings, and the first driving bevel gear 4 is installed on the extension shaft 3 with an interference fit, and the upper side of the first driving bevel gear 4 is meshed with the first driven bevel gear 5. The wheel core of the first driven bevel gear 5 is fitted with a driven shaft 6 with an interference fit. The driven shaft 6 is vertically upward and the driven shaft 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com