Warehouse management system

A storage management system and storage technology, applied in the field of storage management systems, can solve time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

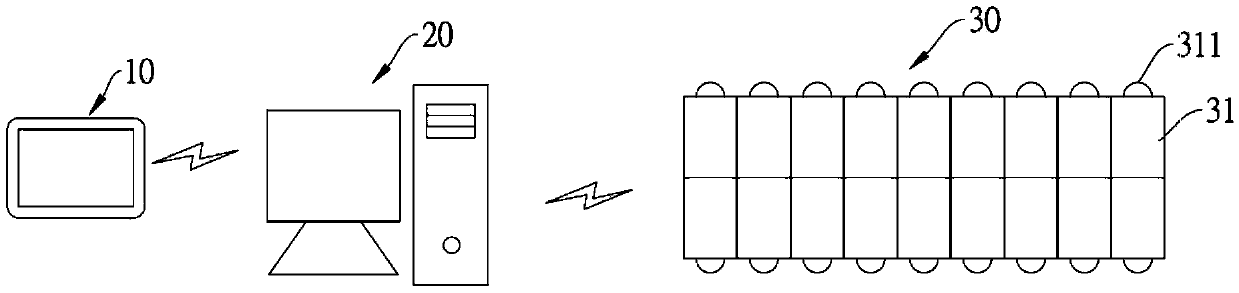

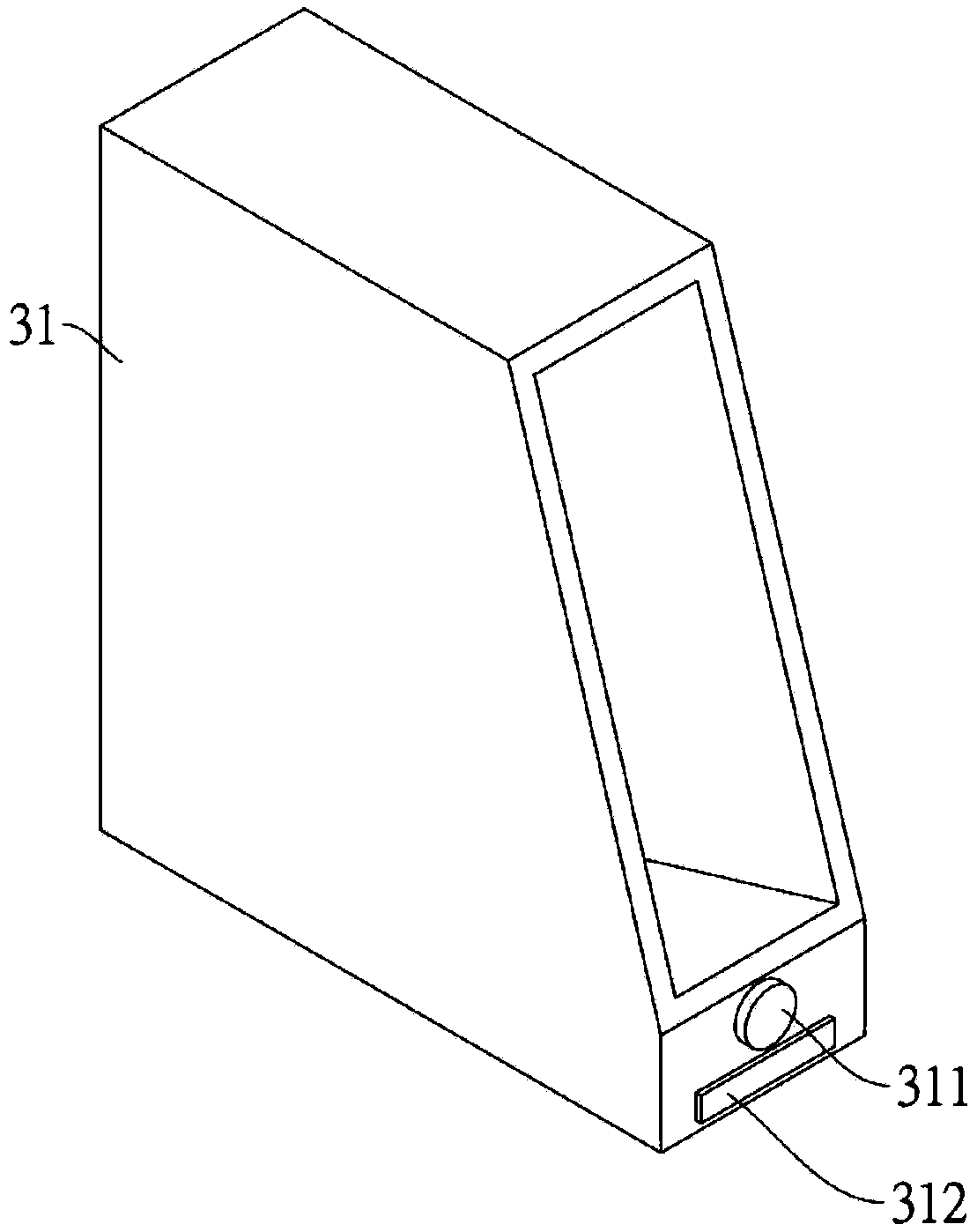

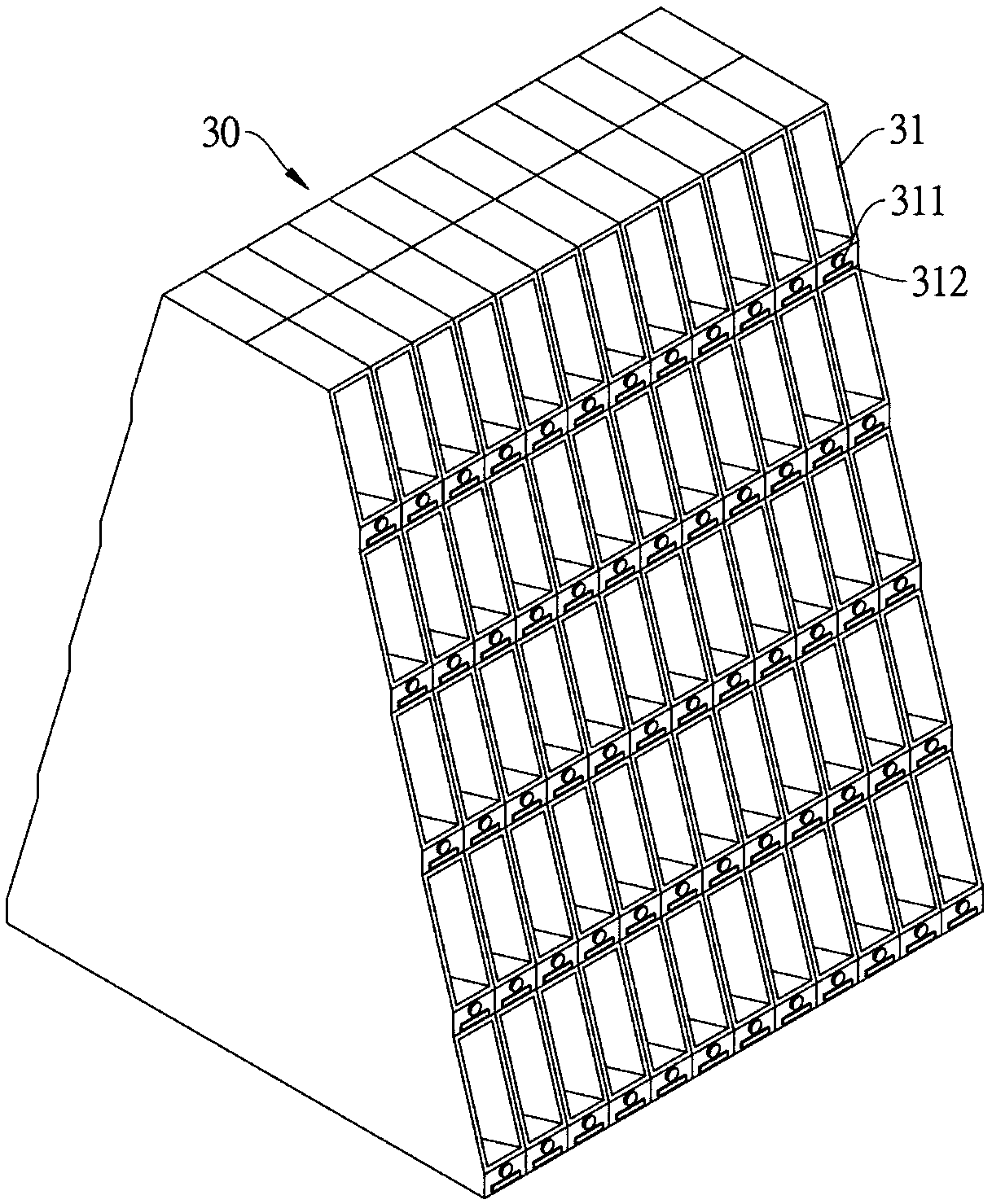

[0023] like Figure 1-5 As shown, a storage management system includes an operating device 10 , a storage control device 20 and a storage device 30 . The operating device 10 can be, for example, a smart phone or a tablet computer, which can be pre-loaded with a predetermined color through a software system. Preferably, the operating device 10 can provide the user with a choice of a variety of colors as the predetermined color. color. The storage control device 20 is connected to the operating device 10, and the storage control device 20 is provided with a database, which can be used to store a storage structure including a plurality of material integration information, and the storage structure can be programmed by software, For example, the material storage structure can be an enterprise resource planning (Enterprise Resource ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com