Connector assembly and equipment box

A technology of connector components and equipment boxes, applied in the direction of connection, fixed connection, electrical components, etc., can solve the problems of difficult assembly of components, difficult bending of wire 04, and limitation of the application range of wire transfer methods, so as to improve applicability, The effect of increasing the effective bending length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

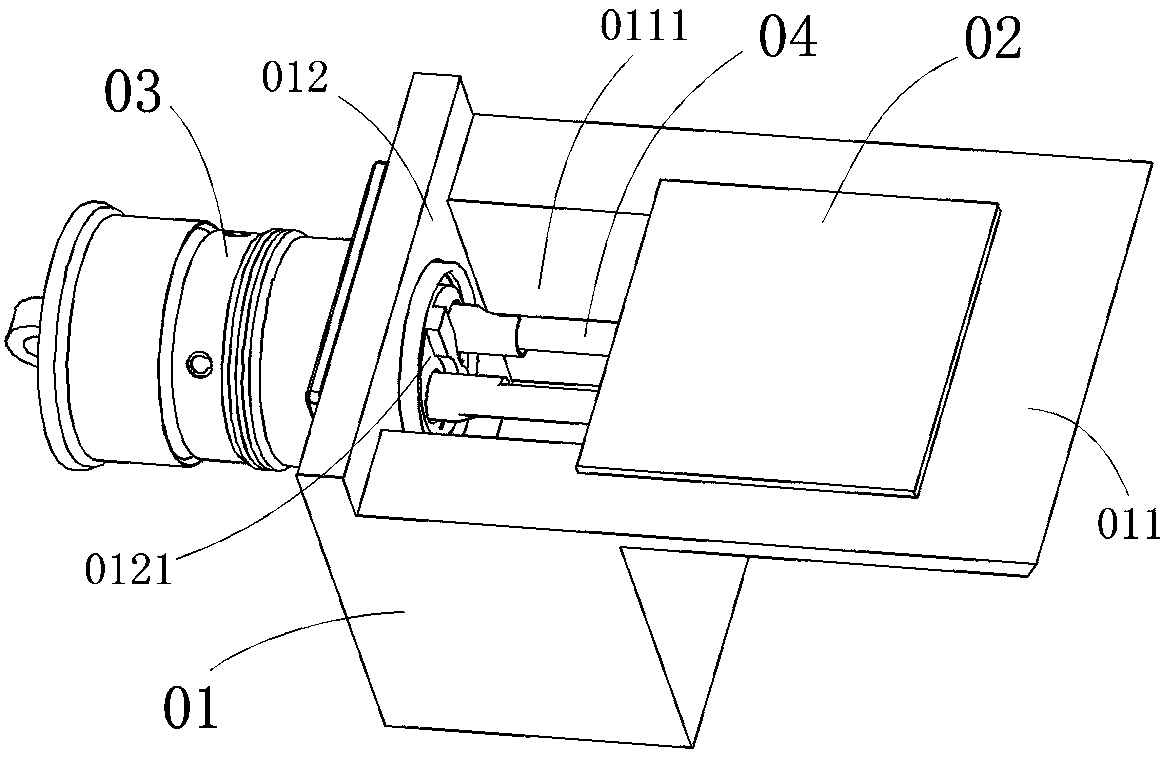

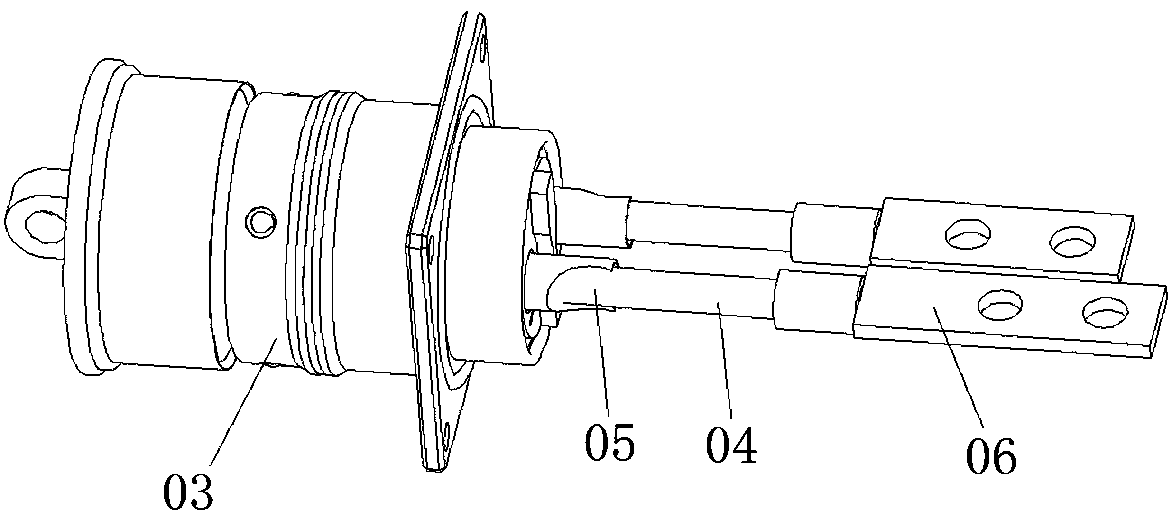

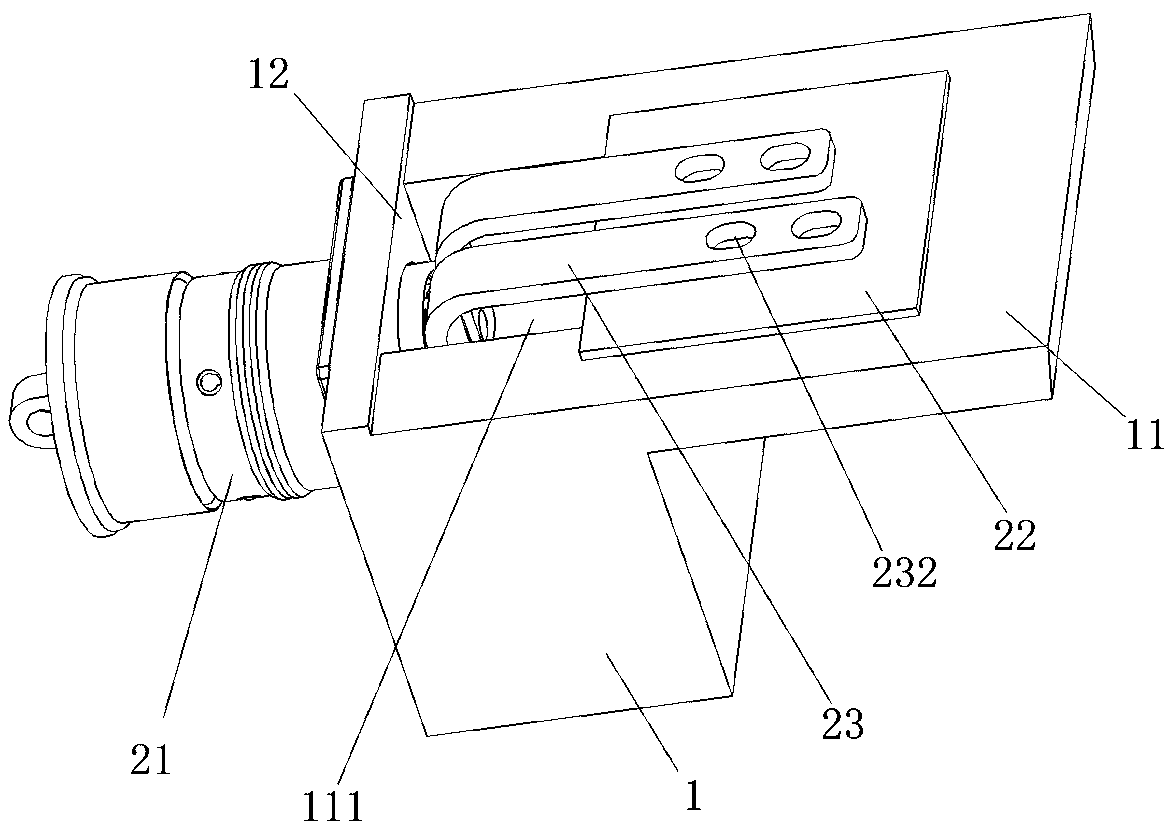

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The main idea of the present invention is: for the connection between the external socket and the printed board that needs to be in a very close relative position on the traditional equipment box, since there is a certain distance between the printed board and the external socket, the wires connected between the two It needs to be bent to realize simultaneous connection with the two. When the two are very close, the required wire is generally shorter, and the two ends of the wire need to be welded with crimping parts and connectors. The phenomenon of tin climbing leads to a very limited part of the wire that can be bent, which makes the connection between the transferred wire and the external socket and the printed board very inconvenient, and it is difficult to bend the wire to achieve correct alignment and connection; the present invention prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com