Sewage treating agent dissolving device

A dissolving device and sewage treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Problems such as the same amount of feeding, to avoid different feeding amounts and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

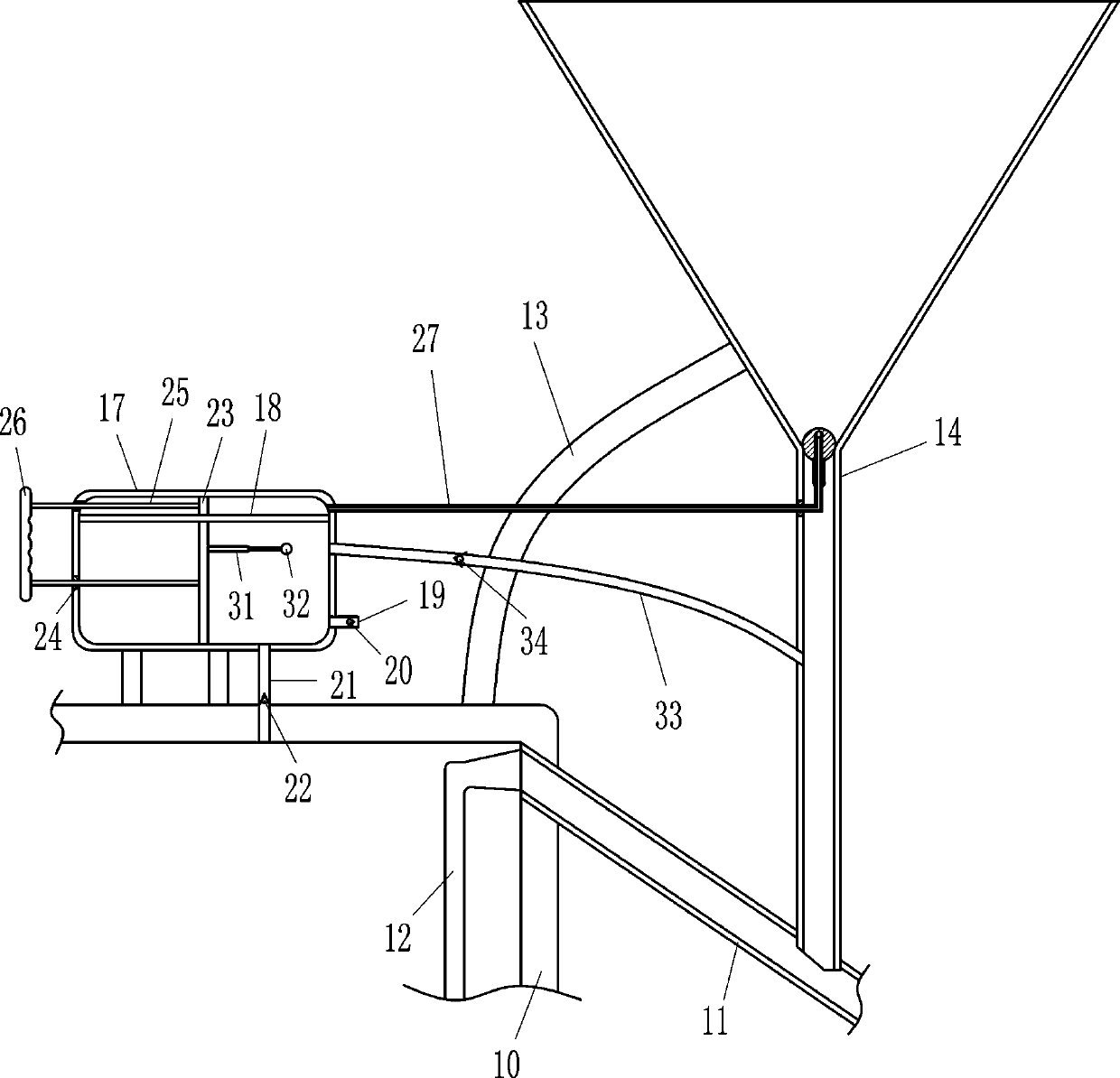

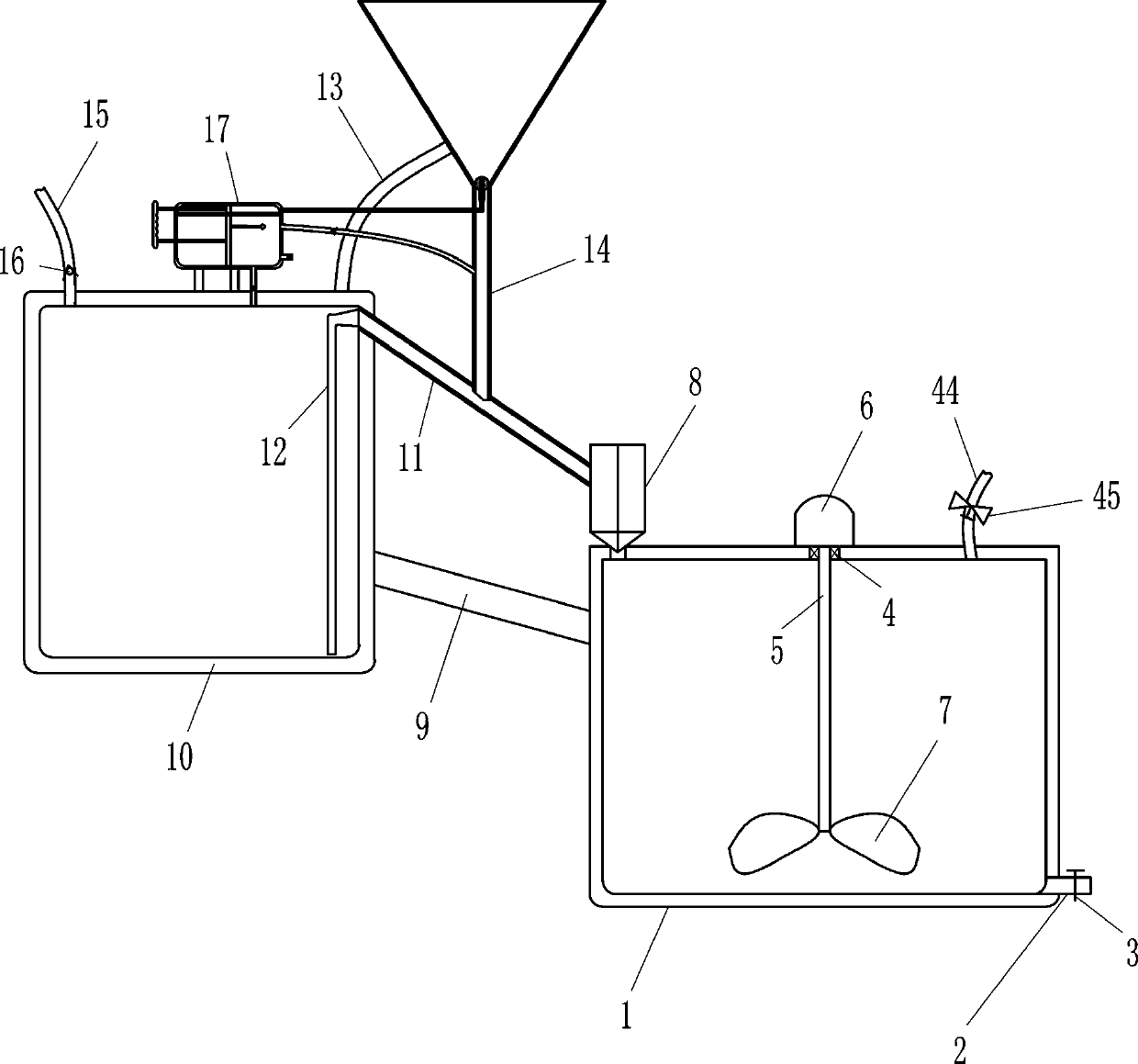

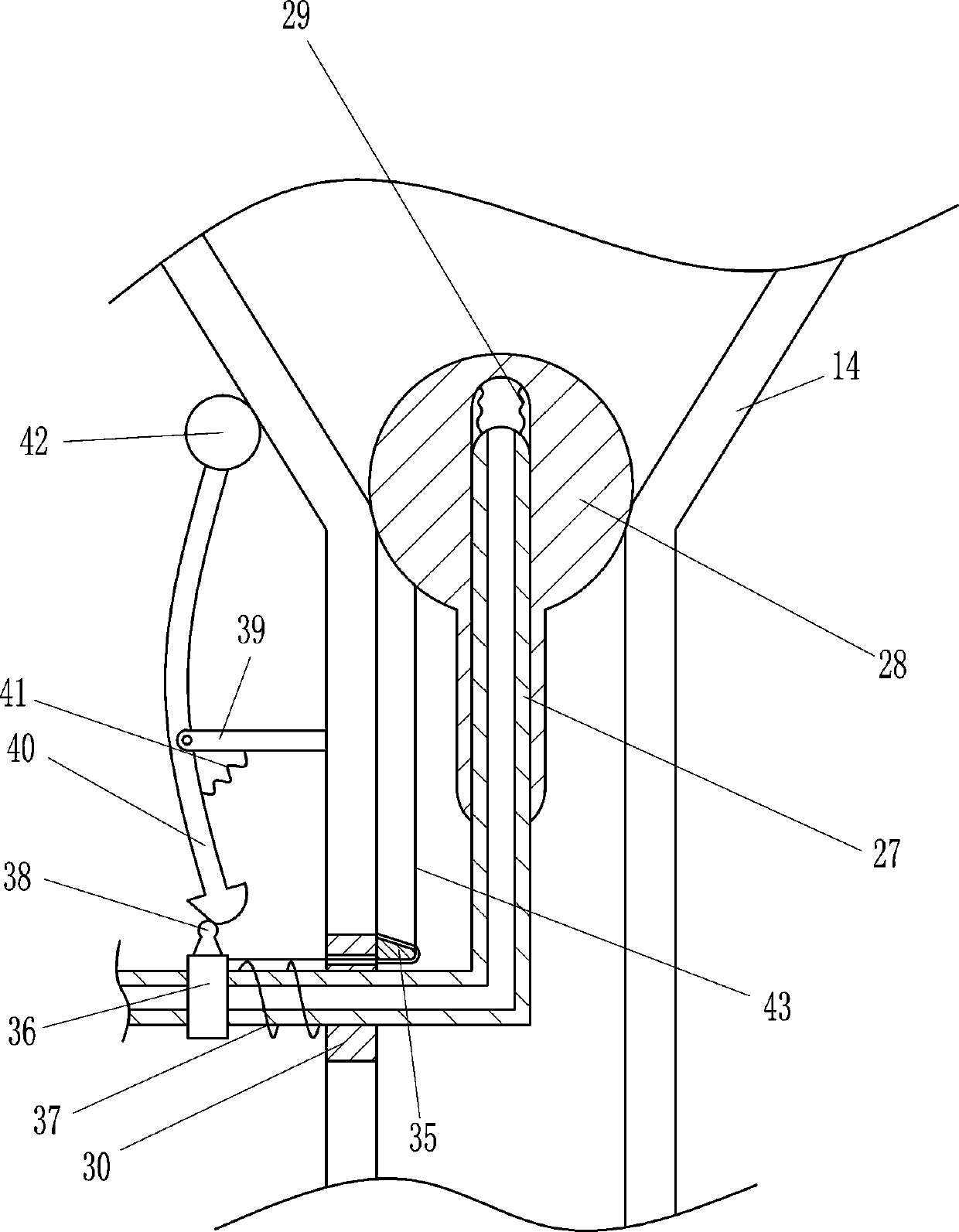

Embodiment 1

[0019] A sewage treatment agent dissolving device, such as Figure 1-3As shown, it includes a large box 1, a discharge pipe 2, a valve 3, a bearing seat 4, a rotating rod 5, a motor 6, a blade 7, a cyclone 8, a connecting rod 9, a small box 10, and a mixing pipe 11 , hard water pipe 12, pole 13, storage hopper 14, water inlet pipe 15, first one-way valve 16, cylinder body 17, dividing plate 18, air inlet pipe 19, second one-way valve 20, air outlet pipe 21, third One-way valve 22, piston 23, guide sleeve 24, guide rod 25, pull rod 26, L-shaped pipe 27, retaining ball 28, first spring 29 and sealing ring 30, and the lower right side of the large box body 1 is provided with a discharge pipe 2. There is a valve 3 on the discharge pipe 2, a bearing seat 4 is embedded in the middle of the top of the large box body 1, a rotating rod 5 is connected to the bearing seat 4, a motor 6 is installed in the middle of the top of the large box body 1, and the motor 6 The output shaft is conn...

Embodiment 2

[0021] A sewage treatment agent dissolving device, such as Figure 1-3 As shown, it includes a large box 1, a discharge pipe 2, a valve 3, a bearing seat 4, a rotating rod 5, a motor 6, a blade 7, a cyclone 8, a connecting rod 9, a small box 10, and a mixing pipe 11 , hard water pipe 12, pole 13, storage hopper 14, water inlet pipe 15, first one-way valve 16, cylinder body 17, dividing plate 18, air inlet pipe 19, second one-way valve 20, air outlet pipe 21, third One-way valve 22, piston 23, guide sleeve 24, guide rod 25, pull rod 26, L-shaped pipe 27, retaining ball 28, first spring 29 and sealing ring 30, and the lower right side of the large box body 1 is provided with a discharge pipe 2. There is a valve 3 on the discharge pipe 2, a bearing seat 4 is embedded in the middle of the top of the large box body 1, a rotating rod 5 is connected to the bearing seat 4, a motor 6 is installed in the middle of the top of the large box body 1, and the motor 6 The output shaft is con...

Embodiment 3

[0024] A sewage treatment agent dissolving device, such as Figure 1-3 As shown, it includes a large box 1, a discharge pipe 2, a valve 3, a bearing seat 4, a rotating rod 5, a motor 6, a blade 7, a cyclone 8, a connecting rod 9, a small box 10, and a mixing pipe 11 , hard water pipe 12, pole 13, storage hopper 14, water inlet pipe 15, first one-way valve 16, cylinder body 17, dividing plate 18, air inlet pipe 19, second one-way valve 20, air outlet pipe 21, third One-way valve 22, piston 23, guide sleeve 24, guide rod 25, pull rod 26, L-shaped pipe 27, retaining ball 28, first spring 29 and sealing ring 30, and the lower right side of the large box body 1 is provided with a discharge pipe 2. There is a valve 3 on the discharge pipe 2, a bearing seat 4 is embedded in the middle of the top of the large box body 1, a rotating rod 5 is connected to the bearing seat 4, a motor 6 is installed in the middle of the top of the large box body 1, and the motor 6 The output shaft is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com