Intermediate support connector transition structure of pipe spiral conveyer

A screw conveyor and intermediate support technology, which is applied in packaging and other directions, can solve problems such as easy material blockage, narrow space, abnormal operation of the conveyor, etc., and achieve the effect of increasing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

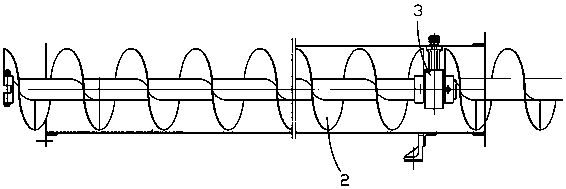

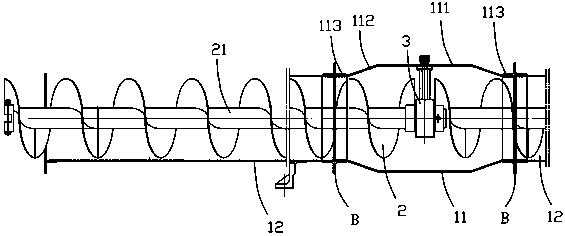

[0015] A transitional structure for the intermediate support connecting body of a tubular screw conveyor, such as figure 2 As shown, it includes a screw transport outer pipe, a spiral channel 2, an intermediate supporting connector 3 that is arranged on the screw transport outer tube and is connected to the rotating shaft 21 of the spiral channel, and the spiral channel 2 is located in the screw transport outer tube. For transporting materials, the screw outer tube with intermediate support connector is now called transition outer tube 11, and the screw outer tube without intermediate support connector is called delivery outer tube 12. For the problem of material blockage at the location where the support connecting body 3 is set, in this embodiment, the diameter of the transition outer tube 11 is set to be larger than the diameter of the delivery outer tube 12, and the transition outer tube 11 seems to form a section of bulging transition joint, which increases the The space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com