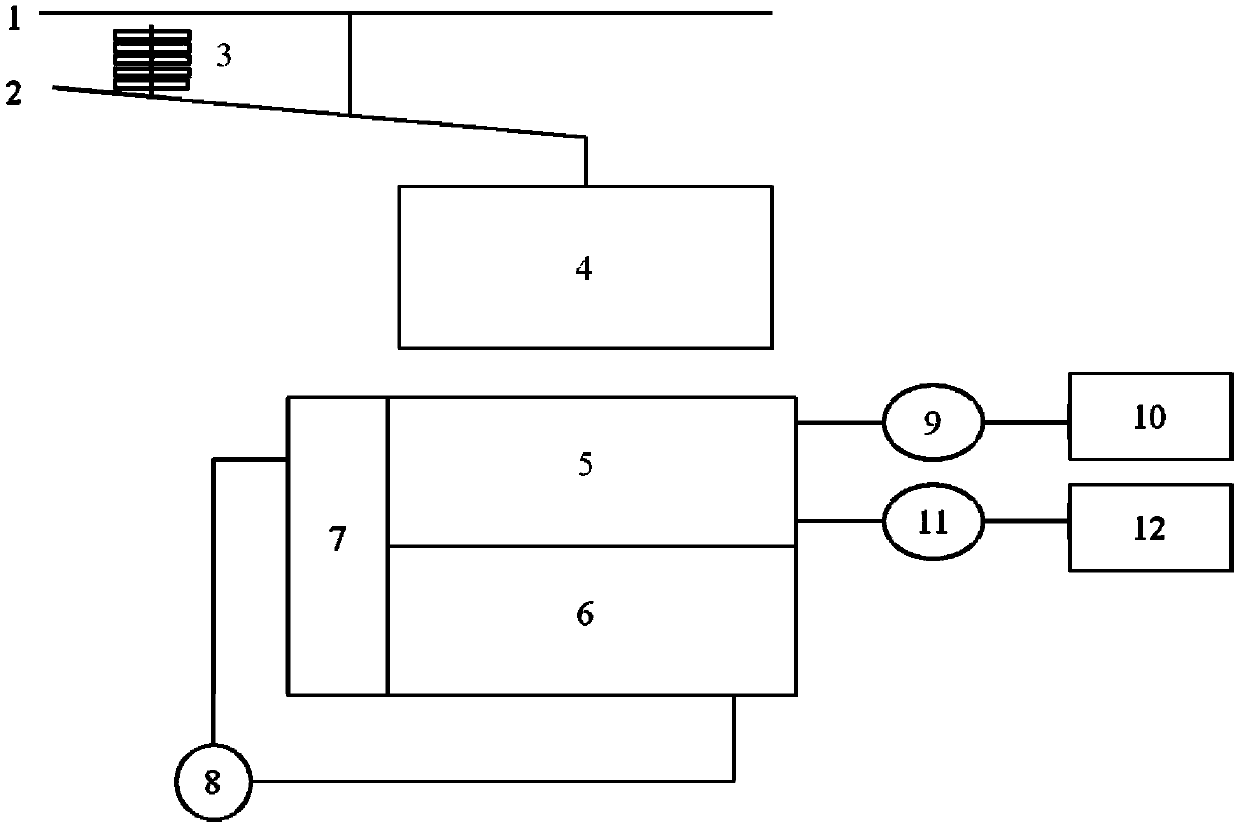

Shape-preserving acid-cleaning device for large-caliber planar element and cleaning method

A flat element and large-diameter technology, applied in the field of large-diameter flat components, can solve problems such as affecting the damage resistance threshold of components, and achieve the effect of improving the surface damage threshold, convenient operation and effective removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

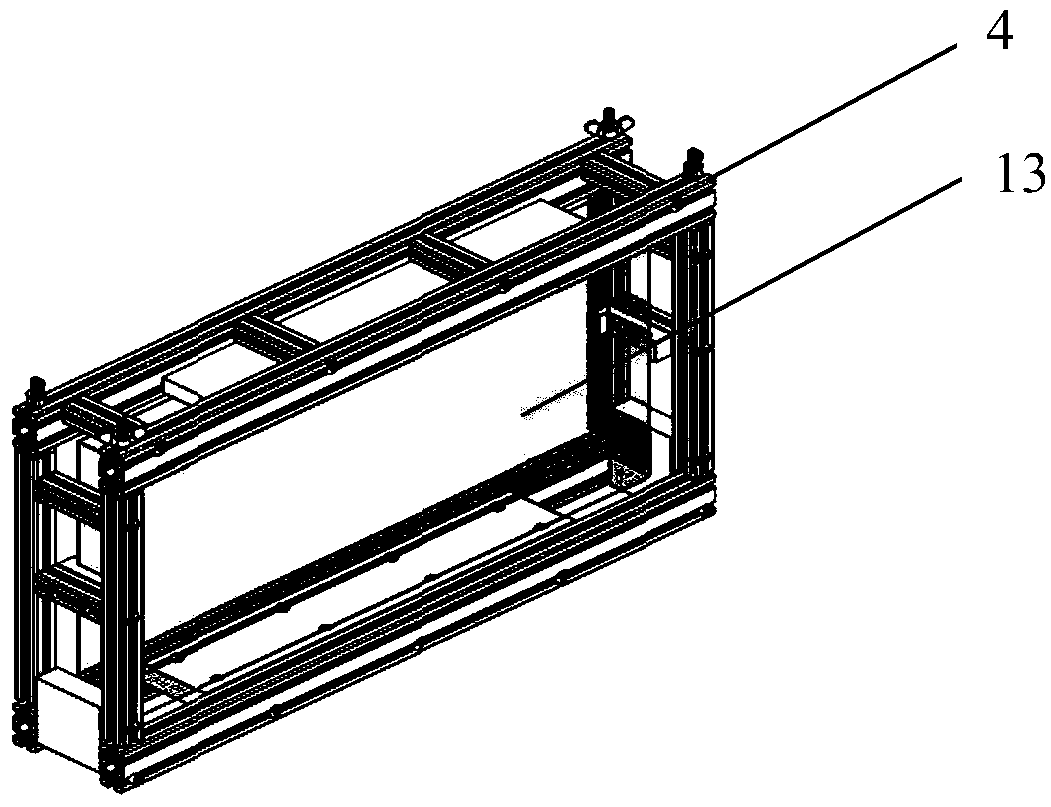

Method used

Image

Examples

Embodiment 1

[0026] For a planar fused silica element with a specification of 810mm×430mm×90mm, the initial surface shape is 0.3λ (λ=632.8nm), and it is required to uniformly etch 60nm to remove the polishing layer without destroying the original surface shape.

[0027] A method for cleaning large-diameter planar components using a conformal pickling device for large-diameter planar components comprises the following steps:

[0028] 1) Prepare the mixed aqueous solution of hydrofluoric acid and ammonium fluoride, wherein the weight percentage of hydrofluoric acid is 1.1%, the weight percentage of ammonium fluoride is 14.8%, and the prepared hydrofluoric acid and ammonium fluoride are mixed The aqueous solution is added in the first pickling tank 6 and the second pickling tank 7, and the liquid level height of the first pickling tank 6 should be able to ensure that there are no large-diameter planar components; inject deionized water into the water washing tank 5, when the large When the ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap