Method for measuring horizontal angle of nozzle of four-corner tangential burner

A burner nozzle and measurement method technology, which is applied to measuring devices, instruments, optical devices, etc., can solve the problems of large measurement error and difficulty in accurately measuring the horizontal angle of the burner nozzle, and achieves convenient operation, easy implementation, and flexible layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

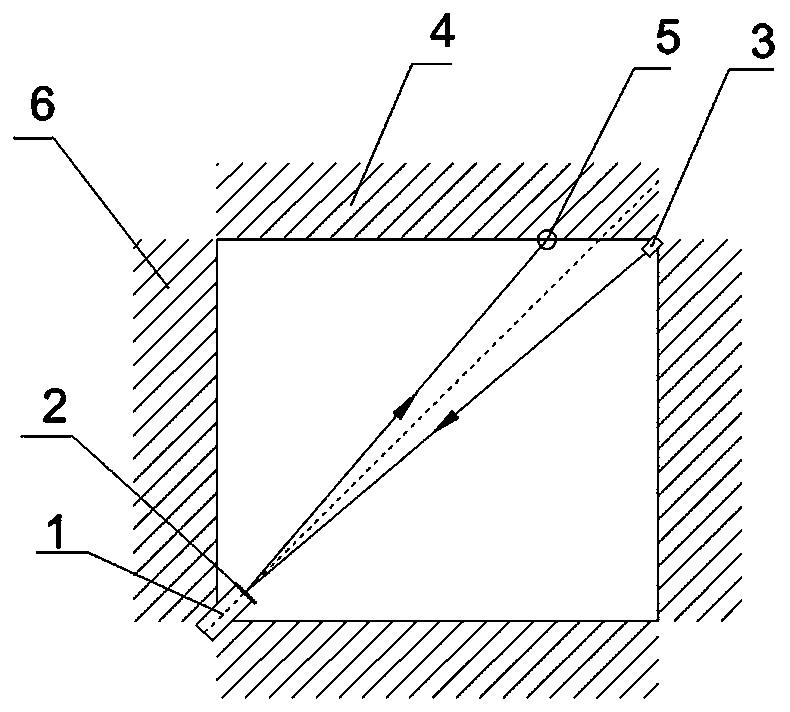

[0028] Calculate the angle between the burner nozzle (1) and the second retaining wall (6) through the inverse cotangent function, and the calculation steps are as follows:

[0029] Step 1, obtain the length a of the first parapet (4);

[0030] Step 2, obtain the distance b between the position of the burner and the first parapet (4);

[0031] Step 3, obtain the distance c between the light falling point (5) and the second parapet (6);

[0032] Step 4, calculate the angle between the burner nozzle (1) and the second parapet (6) by the following formula:

[0033] α=(arccot(b / c)+arccot(b / a)) / 2

[0034] α is the angle between the burner nozzle (1) and the second retaining wall (6), and arccot is the inverse cotangent function.

[0035] When in use, arrange multiple burner nozzles according to actual needs, and calculate the angle between the burner nozzles and the retaining wall one by one according to the above method.

Embodiment 2

[0037] Calculate the angle between the burner nozzle (1) and the second retaining wall (6) through the arcsine function, and the calculation steps are as follows:

[0038] Step 1, obtain the length a of the first parapet (4);

[0039] Step 2, obtain and calculate the distance d between the position of the burner and the light source (3);

[0040] Step 3, obtain the distance c between the light falling point (5) and the second parapet (6);

[0041] Step 4, obtain the distance e between the position of the burner and the falling point of light (5);

[0042] Step 5, calculate the angle between the burner nozzle (1) and the second parapet (6) by the following formula:

[0043] α=(arcsin(c / e)+arcsin(a / d)) / 2

[0044] α is the angle between the burner nozzle (1) and the second retaining wall (6), and arcsin is an arcsine function.

[0045] When in use, arrange multiple burner nozzles according to actual needs, and calculate the angle between the burner nozzles and the retaining w...

Embodiment 3

[0047] Calculate the angle between the burner nozzle (1) and the second retaining wall (6) through the arccosine function, and the calculation steps are as follows:

[0048] Step 1, obtain the distance b between the position of the burner and the first parapet (4);

[0049] Step 2, obtain the distance d between the position of the burner and the light source (3);

[0050] Step 3, obtain the distance e between the position of the burner and the falling point of light (5);

[0051] Step 4, calculate the angle between the burner nozzle (1) and the second parapet (6) by the following formula:

[0052] α=(arccos(b / d)+arccos(b / e)) / 2

[0053] α is the angle between the burner nozzle (1) and the second retaining wall (6), and arccos is an arccosine function.

[0054] When in use, arrange multiple burner nozzles according to actual needs, and calculate the angle between the burner nozzles and the retaining wall one by one according to the above method.

[0055] The horizontal angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com