Measurement and quick vacuumizing method and device for inner cavity vacuum degree of component with tubule

A vacuum degree and vacuum pumping technology, which is applied to measuring devices, pump devices, vacuum gauges, etc., can solve problems such as low production efficiency, long vacuuming time, and large difference in vacuum degree, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

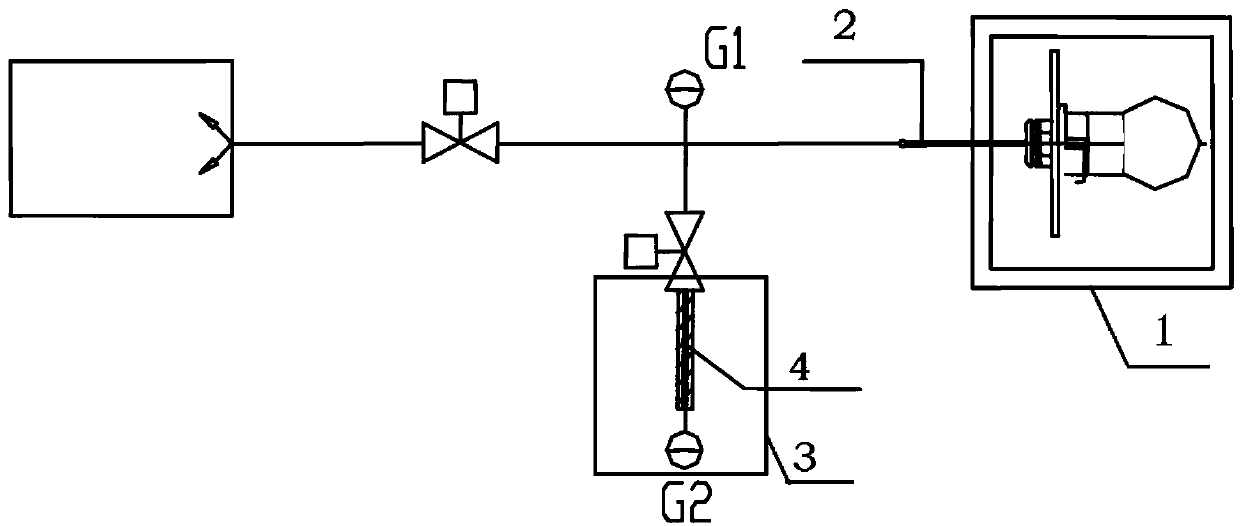

[0017] Embodiment 1 of the present invention: a device for measuring and quickly vacuuming the inner cavity of a thin tube assembly, such as figure 1 As shown, it includes the analog part 3 connected with the thin tube 2 with the thin tube assembly 1, the simulated thin tube 4 of the simulated part 3 has the same inner diameter and length as the thin tube 2, and the vacuum gauge G2 is connected to the end of the simulated thin tube 4, and the thin tube 2 and the simulated thin tube 4 are connected to a vacuum unit, and a vacuum gauge G1 is also connected to the pipeline. For the analog thin tube 4 whose inner diameter is too small to be directly connected to the vacuum gauge, the outer diameter is enlarged so that the analog part is directly sealed and connected with the vacuum gauge G2.

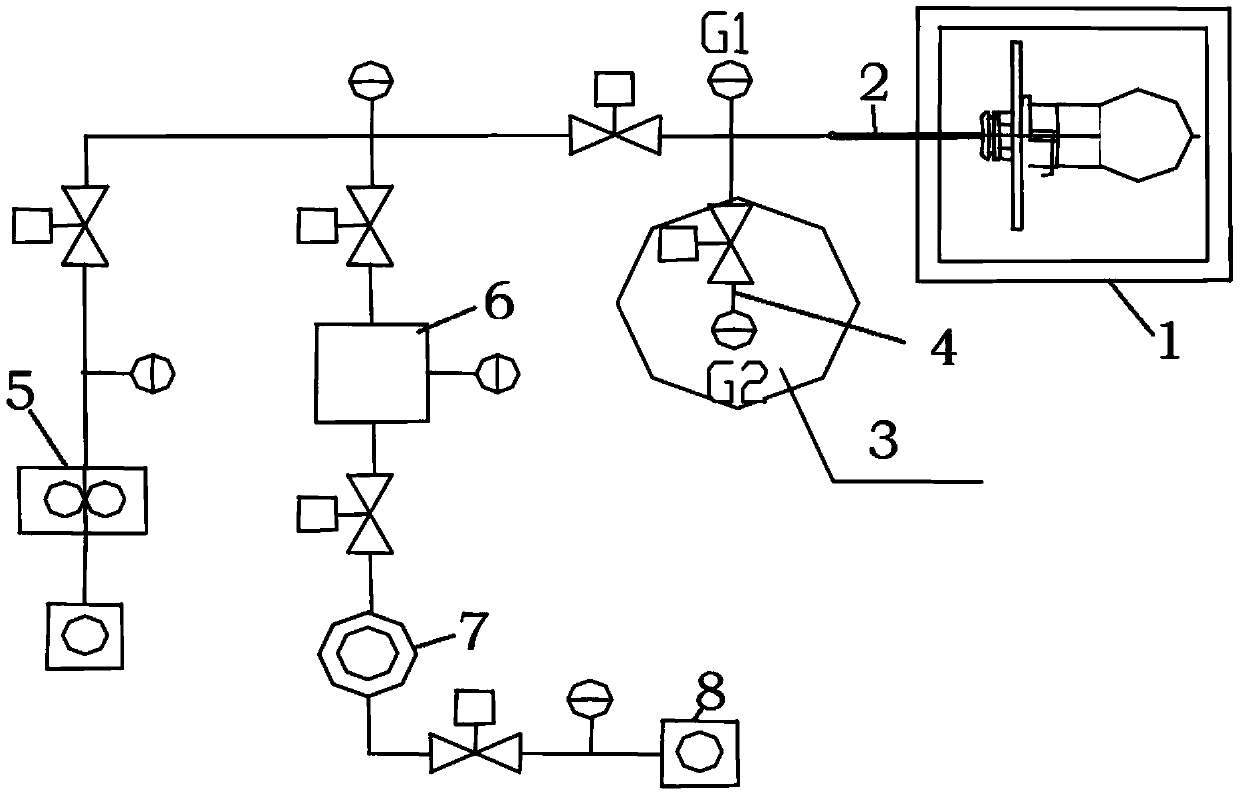

[0018] Such as figure 2 As shown, the thin tube 2 with the thin tube assembly 1 is also connected to the Roots pump unit 5 and the counter vacuum station 6 respectively. The hedging vacuu...

Embodiment 2

[0022] Embodiment 2 of the present invention: a device for measuring and quickly vacuuming the inner cavity of a thin tube assembly, such as figure 1 As shown, it includes a dummy part 3 connected to the thin tube 2 with a thin tube assembly 1, the simulated thin tube 4 of the simulated part 3 has the same inner diameter and length as the thin tube 2, and a vacuum gauge G2 is connected to the end of the simulated thin tube 4.

[0023] When in use, the front section of the narrow tube 2 with the thin tube assembly 1 is connected to the analog part 3 through a three-way valve. Since the simulated thin tube 4 of the simulated part 3 has the same inner diameter and length as the thin tube 2, a vacuum gauge G2 is connected to the end of the simulated thin tube 4 , the vacuum degree of the inner cavity of the assembly with thin tube 1 can be simulated by the vacuum gauge G2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com