Method for automatically optimizing positions of cutting pieces

An automatic optimization and piece cutting technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve the problems of large hole area and waste of fabrics, so as to improve the utilization rate and avoid direct waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

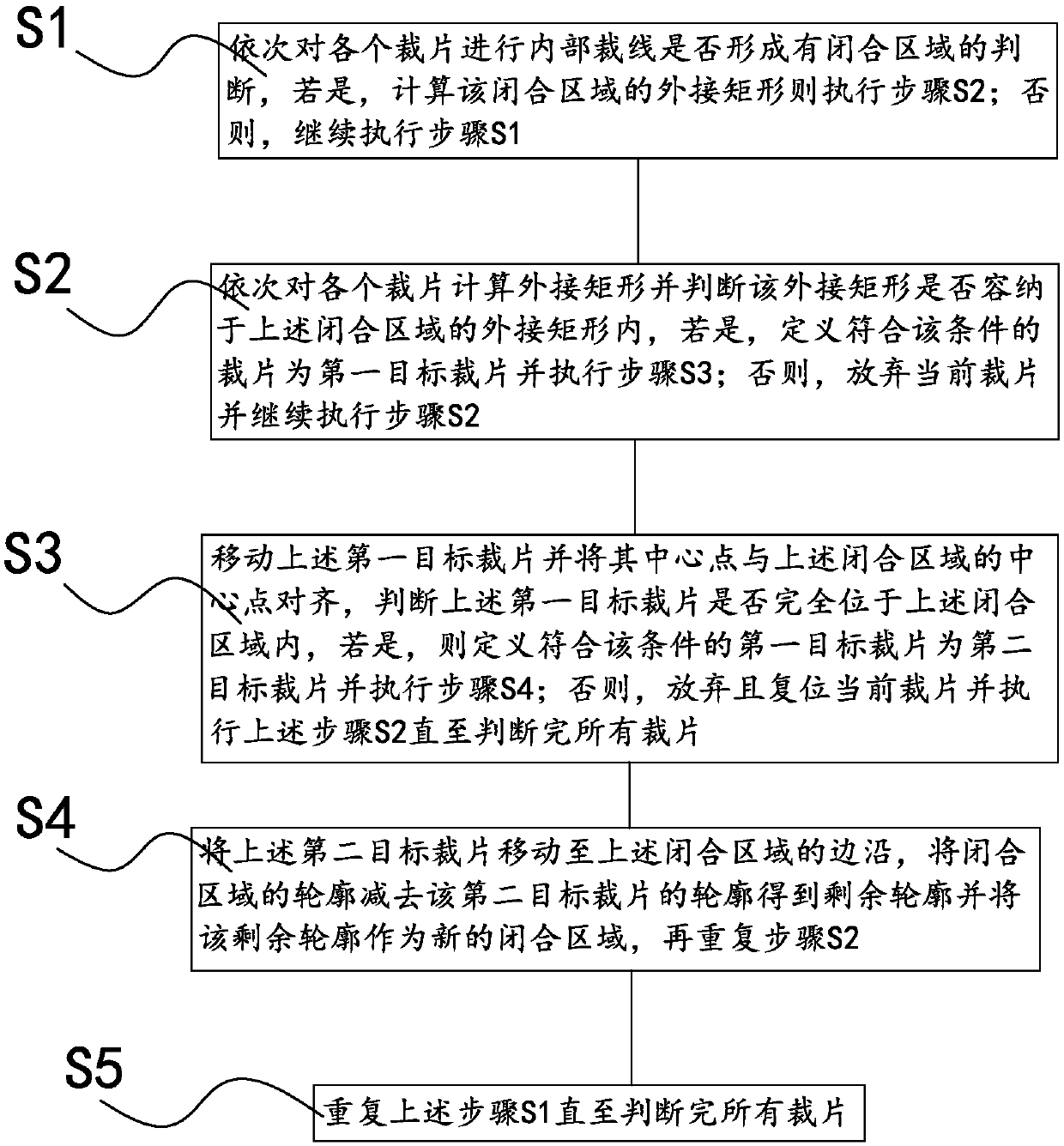

[0023] Such as figure 1 As shown, the method for automatically optimizing the position of the cutting piece comprises the following steps:

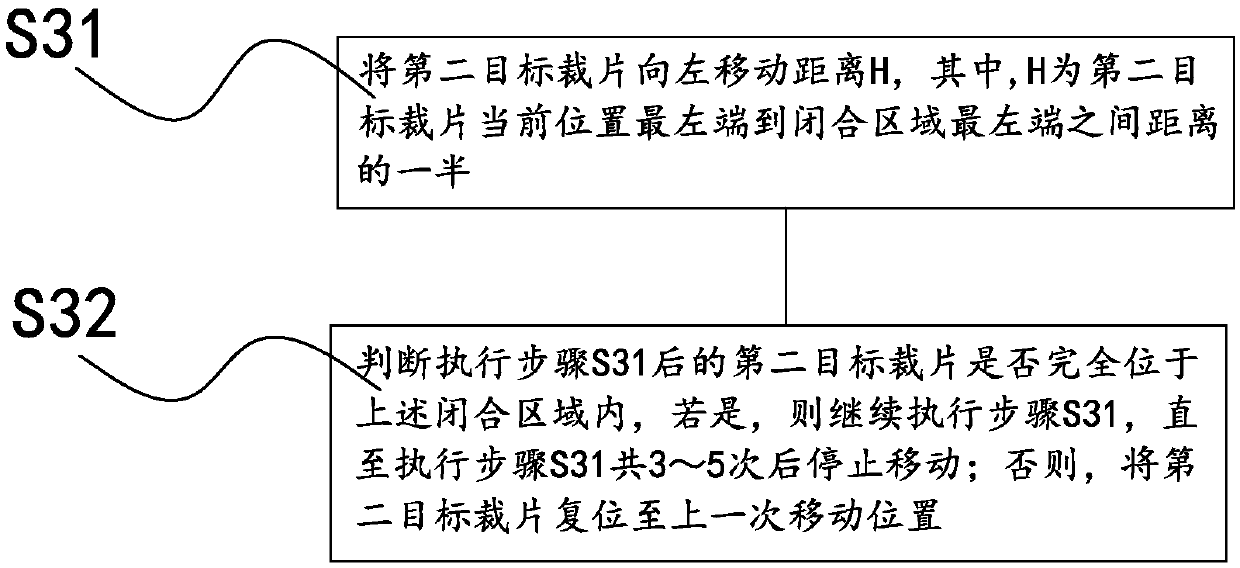

[0024] S1. Carry out judgment on whether the internal cutting line of each cut piece forms a closed area in turn, if so, calculate the circumscribed rectangle of the closed area and then execute step S2; otherwise, continue to execute step S1; when holes need to be cut out on the cut piece, then The edge of the hole is the stitch that needs to be cut, that is, the inner cut line. Only when the cut stitch is a closed area connected end to end, the fabric in the closed area will be cut and pulled out to form a hole. Therefore, it is judged that the inner cut of the piece is Whether the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com