Method for calibrating weight of dyed yarn and method, device and equipment for determining weight of collar and sleeve pieces

A technology for calibrating weight and dyed yarn, applied in computer readable storage medium and computer equipment, production calibration of leader piece, determination of leader piece weight field, can solve the problem of inaccurate weight estimation of dyed yarn, etc., to improve accuracy and correct weight , the effect of avoiding waste of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions, and advantages of this application clearer, the following further describes this application in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the application, but not to limit the application.

[0038] It should be noted that the term "first\second" involved in the embodiments of this application only distinguishes similar objects, and does not represent a specific order of objects. Understandably, "first\second" is allowed The following can be interchanged in a specific order or sequence. It should be understood that the objects distinguished by "first\second" can be interchanged under appropriate circumstances, so that the embodiments of the application described herein can be implemented in an order other than those illustrated or described herein.

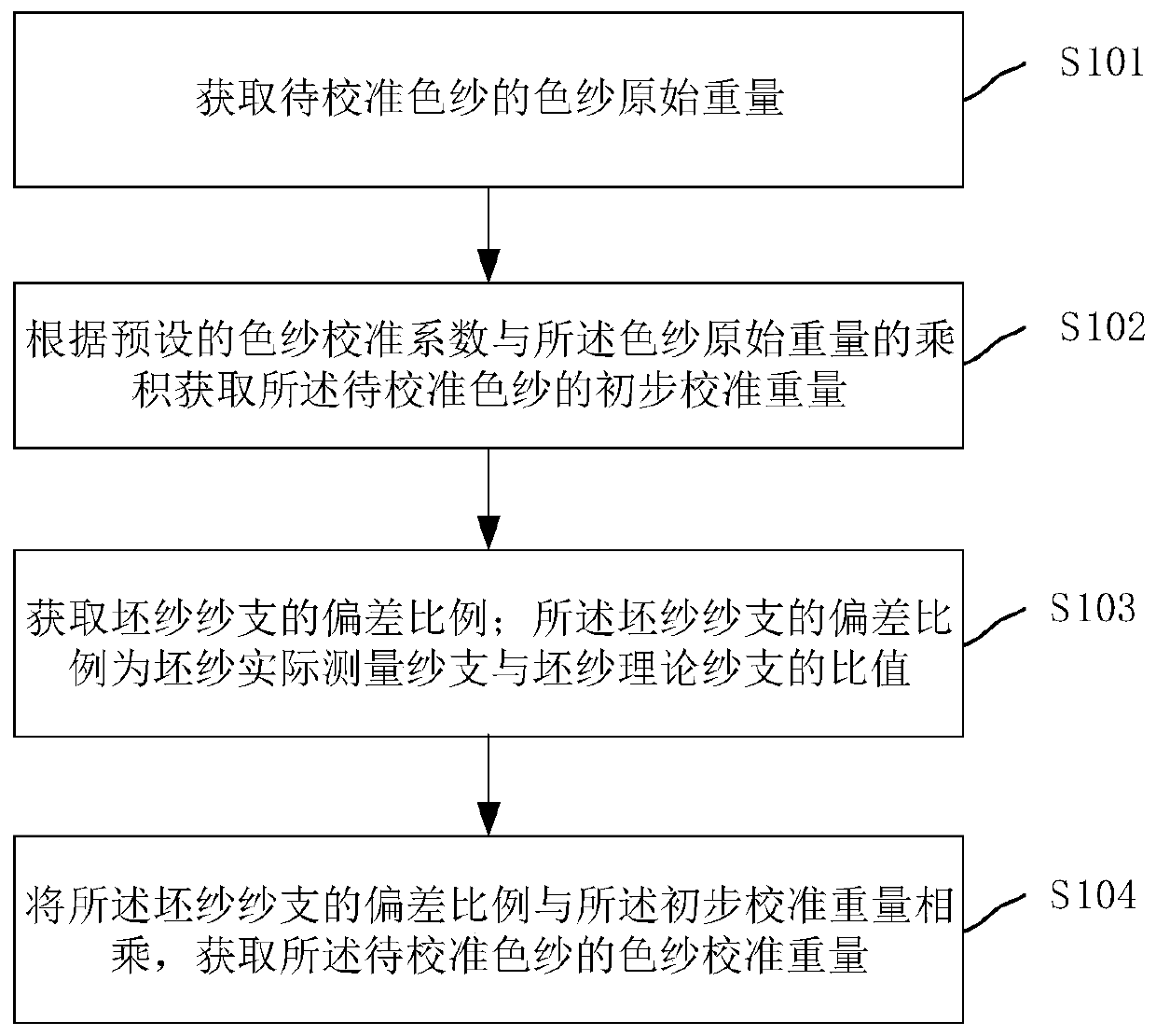

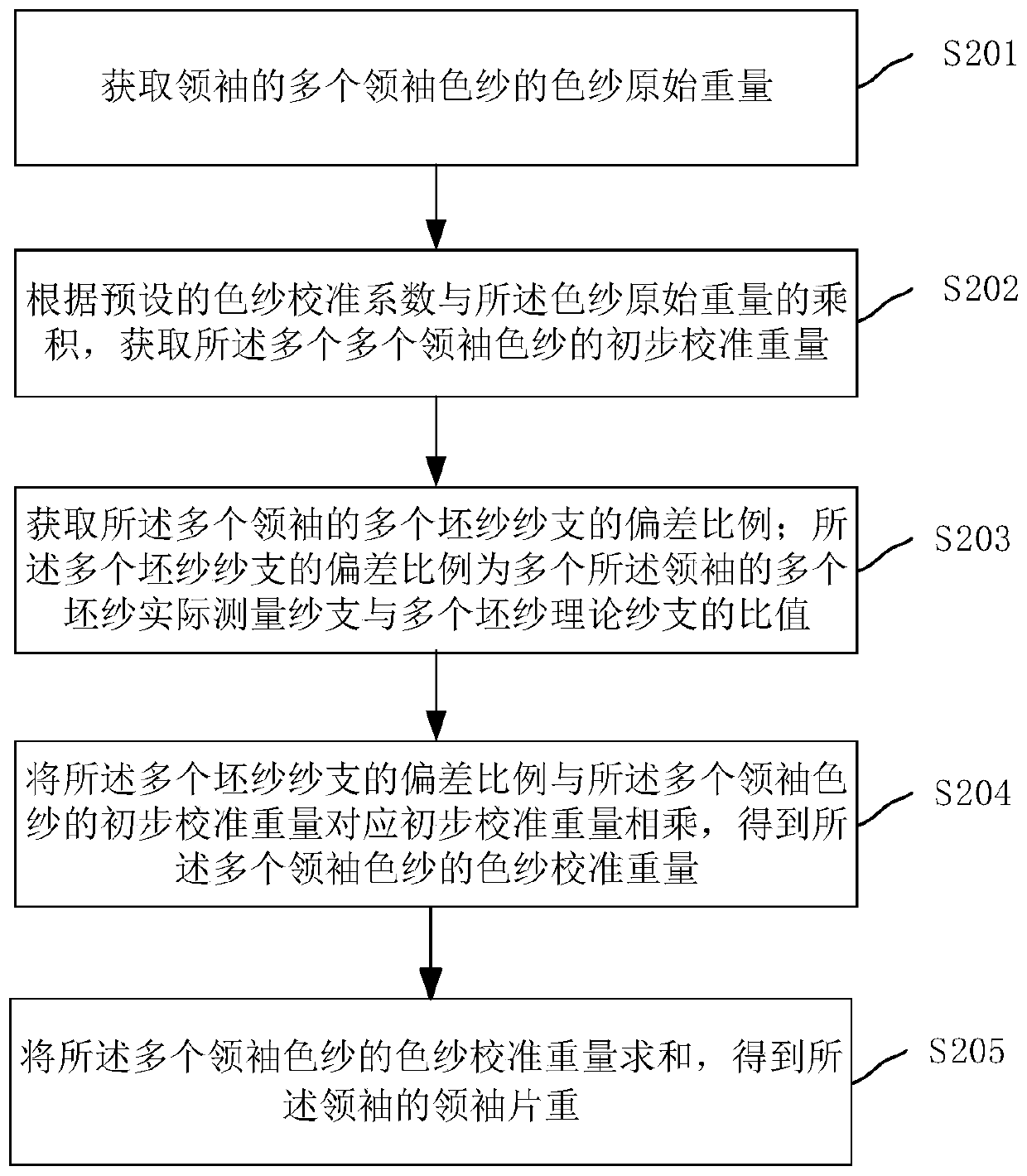

[0039] Such as figure 1 As shown, in one embodiment, a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com