Workpiece bending mechanism and method and pipe bending device

A bending mechanism and workpiece technology, applied in the mechanical field, can solve the problems of workpiece deformation, shape uniformity, consistency, poor accuracy, and no support device, etc., to improve quality, improve bending effect, and good support limit bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

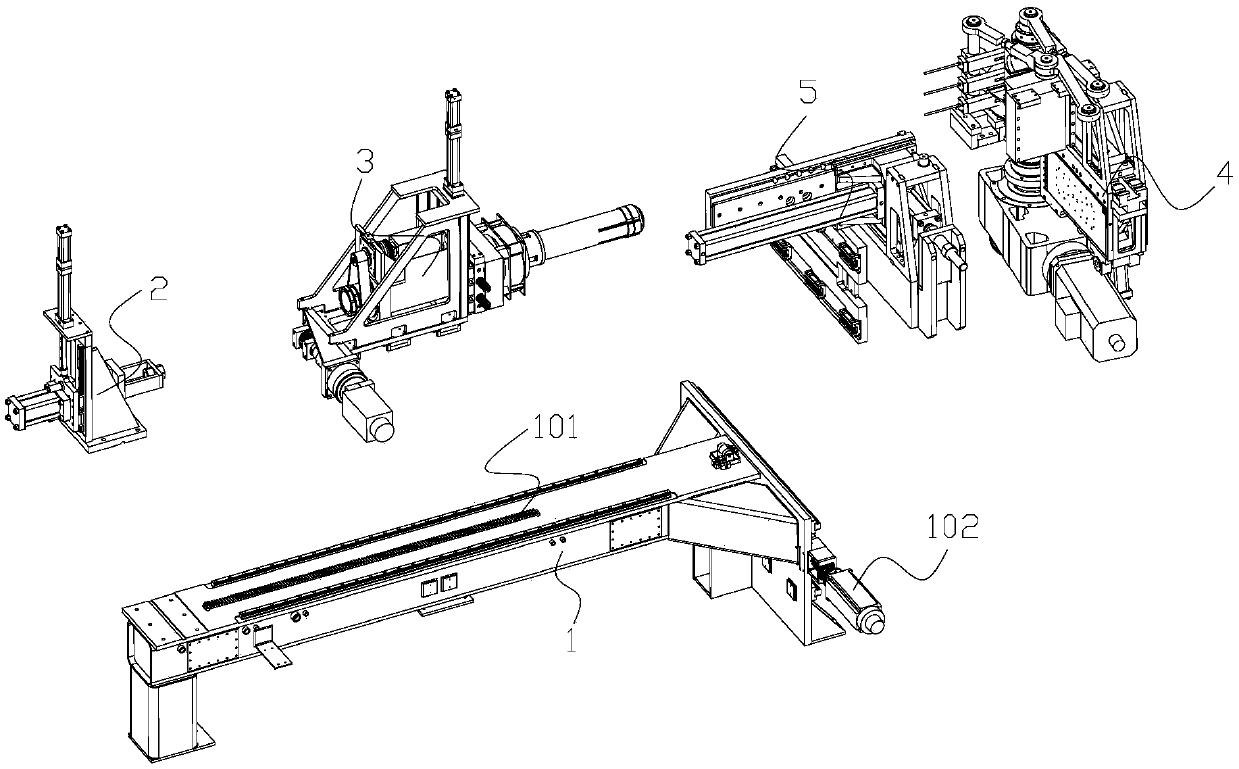

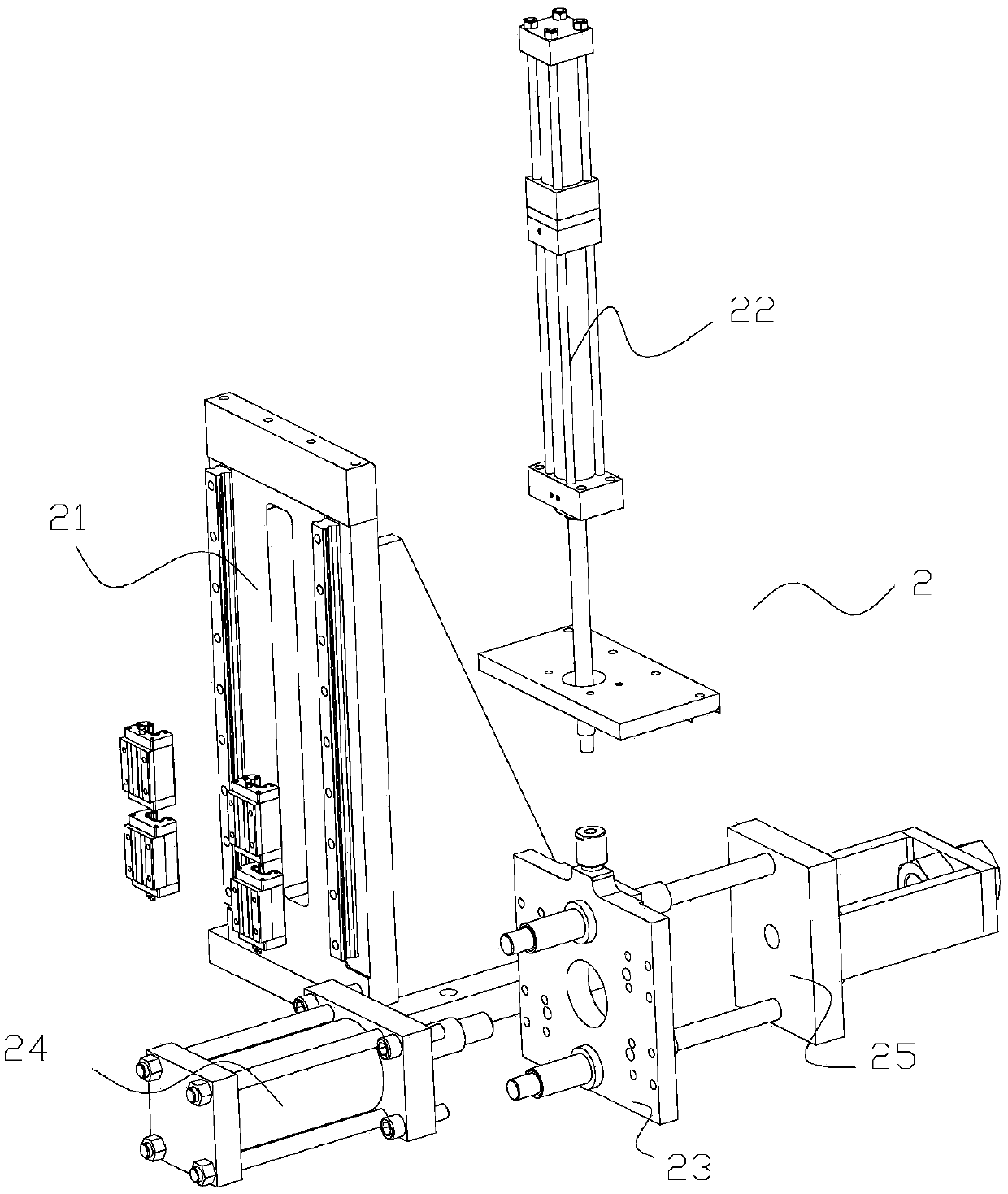

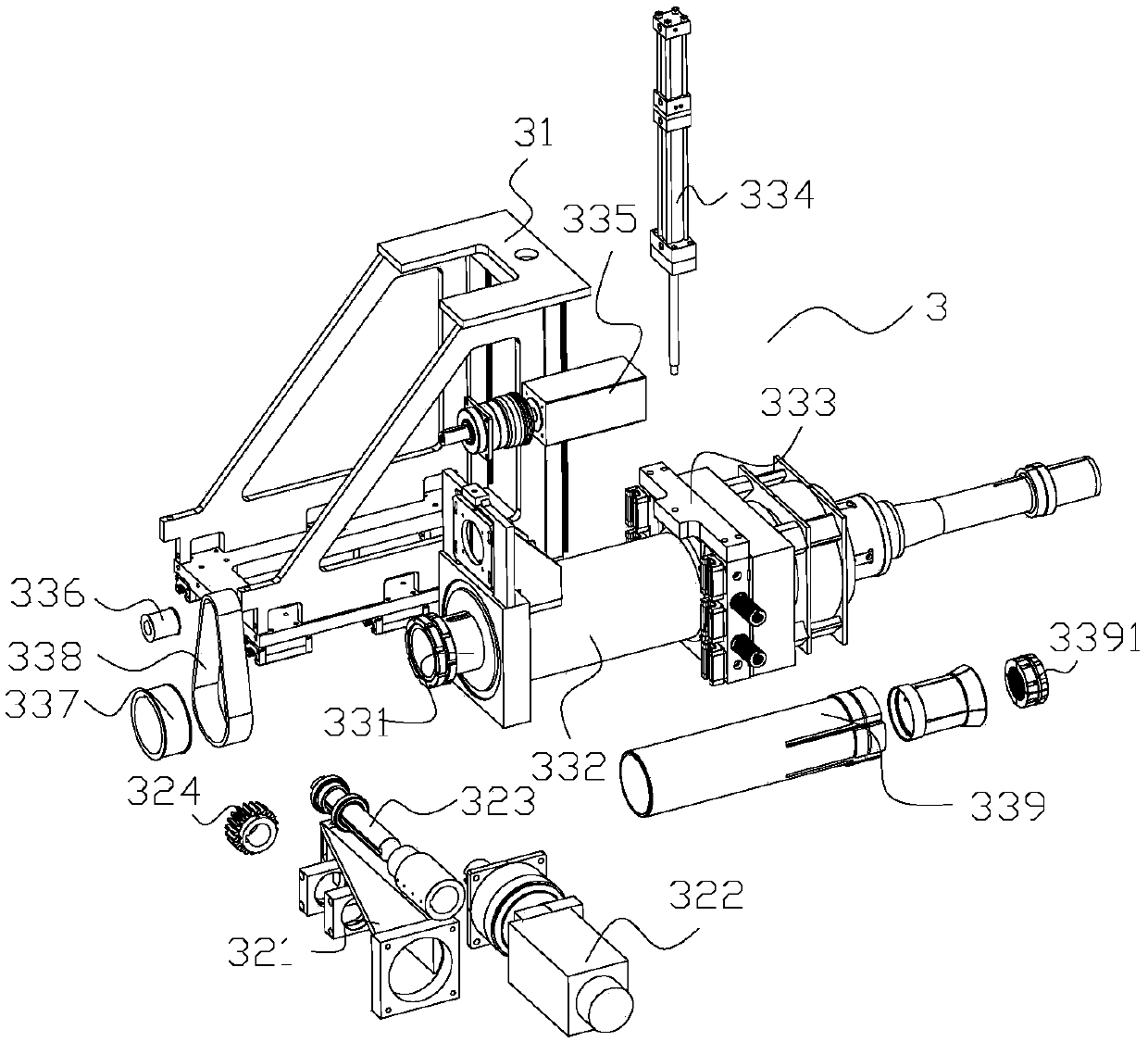

[0026] Such as figure 1 As shown, a pipe bending equipment includes a frame 1, a workpiece support device 2, a workpiece drive device 3, a pipe bending device 4 and a workpiece clamping cooperation device 5; the workpiece support device 2 is arranged on the frame 1 The end of the workpiece support device 2 is used to support the end of the workpiece; the workpiece driving device 3 includes a moving frame 31, a horizontal drive assembly and a rotating lifting assembly; the moving frame 31 is arranged on the frame 1 through a moving slide rail , the horizontal driving assembly is arranged on the moving frame 31, and the horizontal driving assembly can drive the moving frame 31 to move; the rotating lifting assembly is arranged on the moving frame 31, and the rotating lifting assembly can drive the workpiece to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com