Pipeline flange welding positioning tool

A technology for welding positioning tooling and pipe flanges, which is applied to welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Convenience, Quantity Saving, Effects of Reducing the Quantity Used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

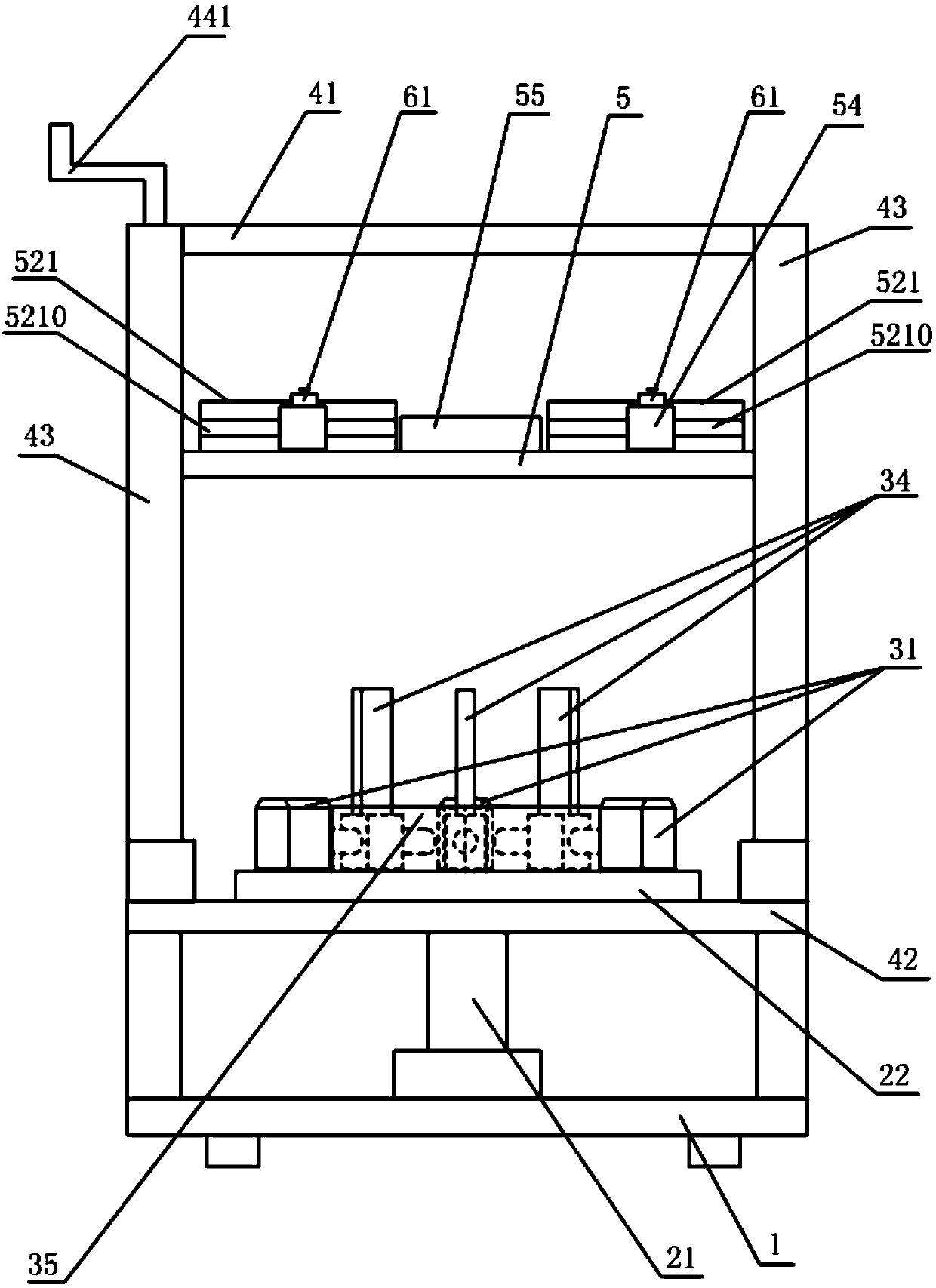

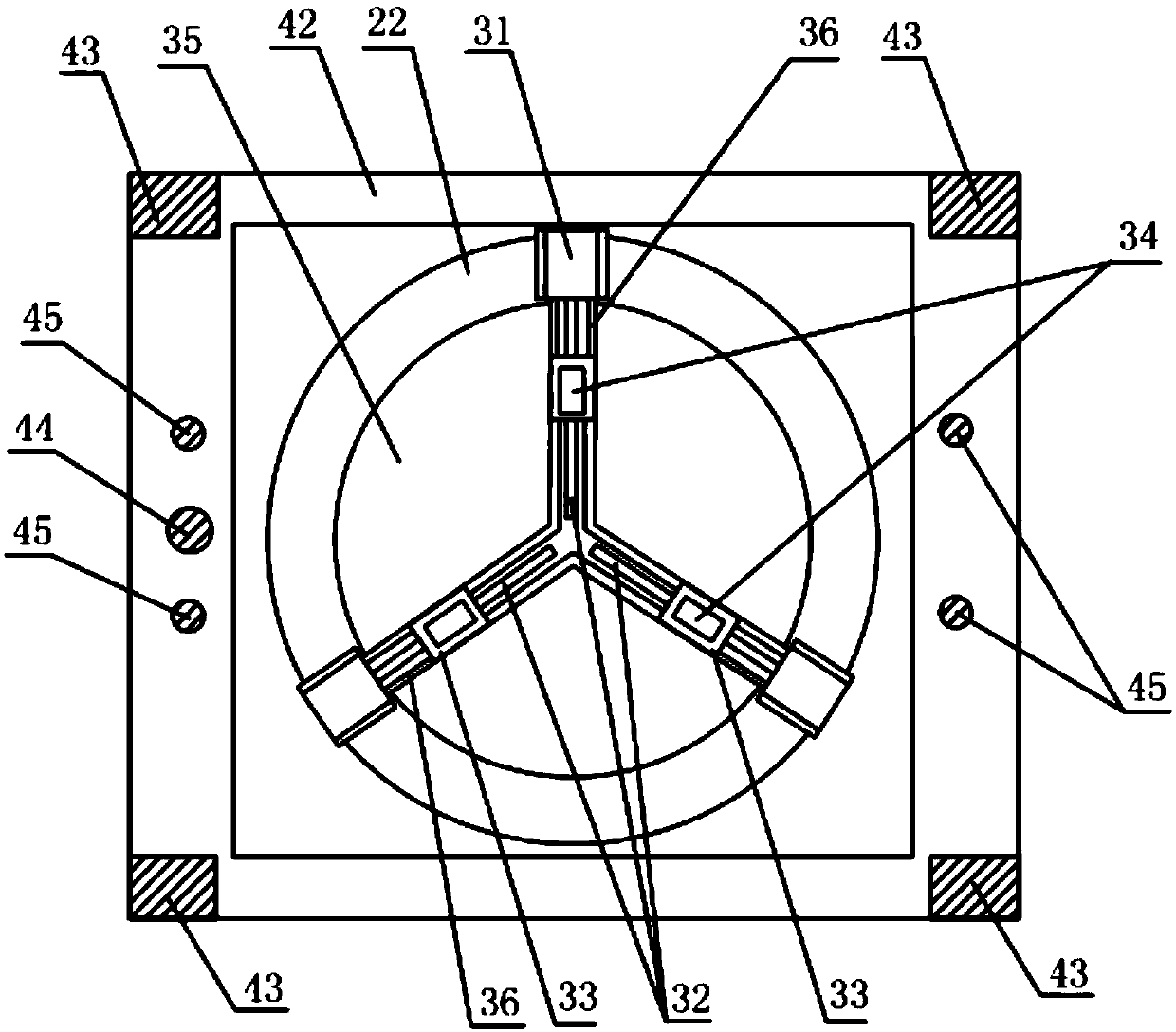

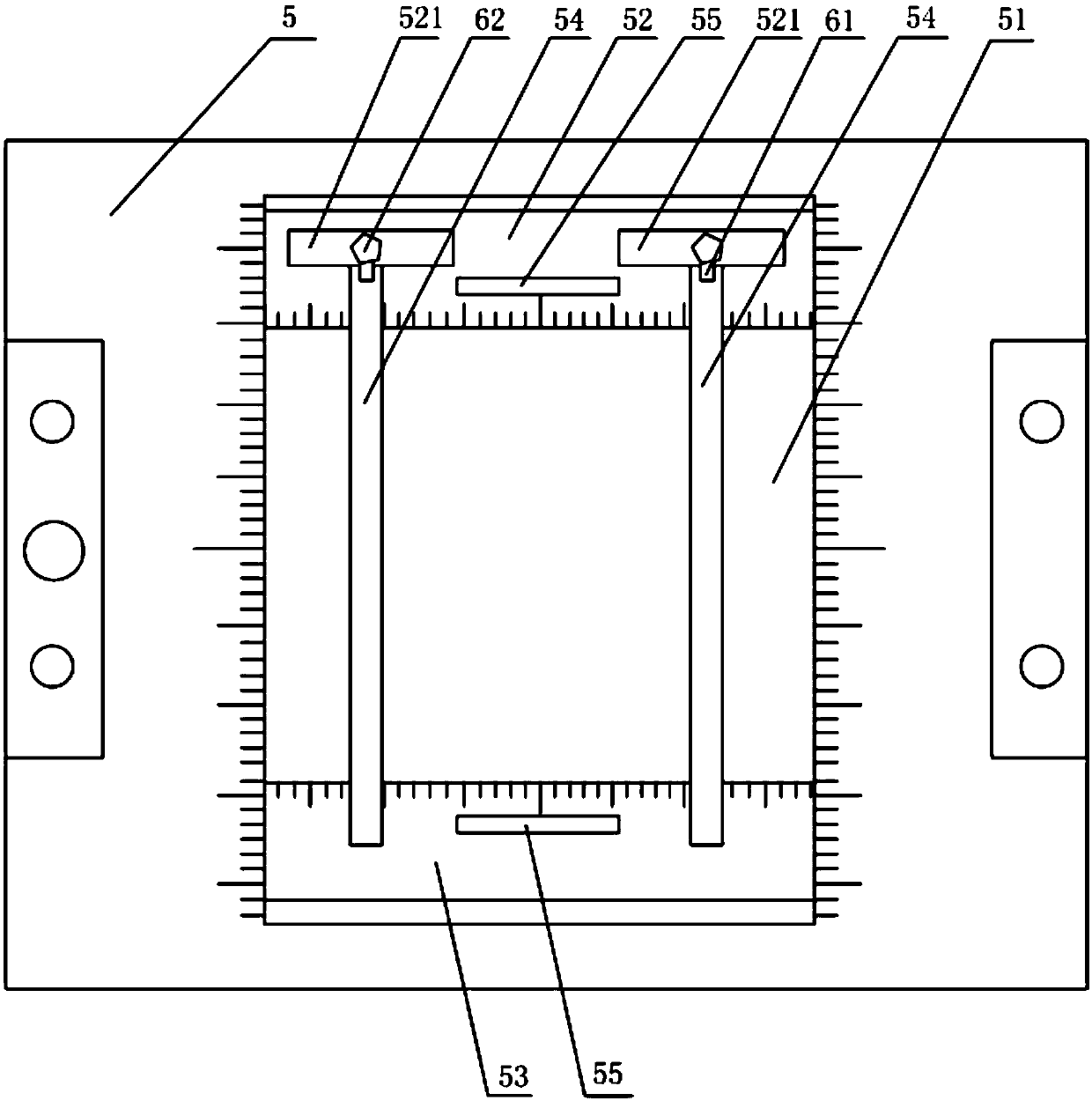

[0026] like Figure 1 to Figure 5As shown, a pipe flange welding positioning tool according to the present invention includes a square base 1 arranged horizontally, the top of the base 1 is vertically rotatably connected to a column 21 through a bearing, and the top of the column 21 is vertically fixedly connected to a The pipe support plate 22, the top of the pipe support plate 22 is fixed with a pipe support assembly, the number of the pipe support assembly is 3, including a motor 31, a first lead screw 32, a slider 33 and a pipe positioning column 34. The centers of the three motors 31 are always located on the same arc, and a circular liner 35 is fixedly arranged in the space surrounded by the three motors 31, and the centers of the arc and the liner 35 are located at On the extension line of the central axis of the column 21, three sliding slots 36 are opened in the radial direction on the lining plate 35, and the included angle between two adjacent sliding slots 36 is 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com