Patents

Literature

50results about How to "Convenient spot welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

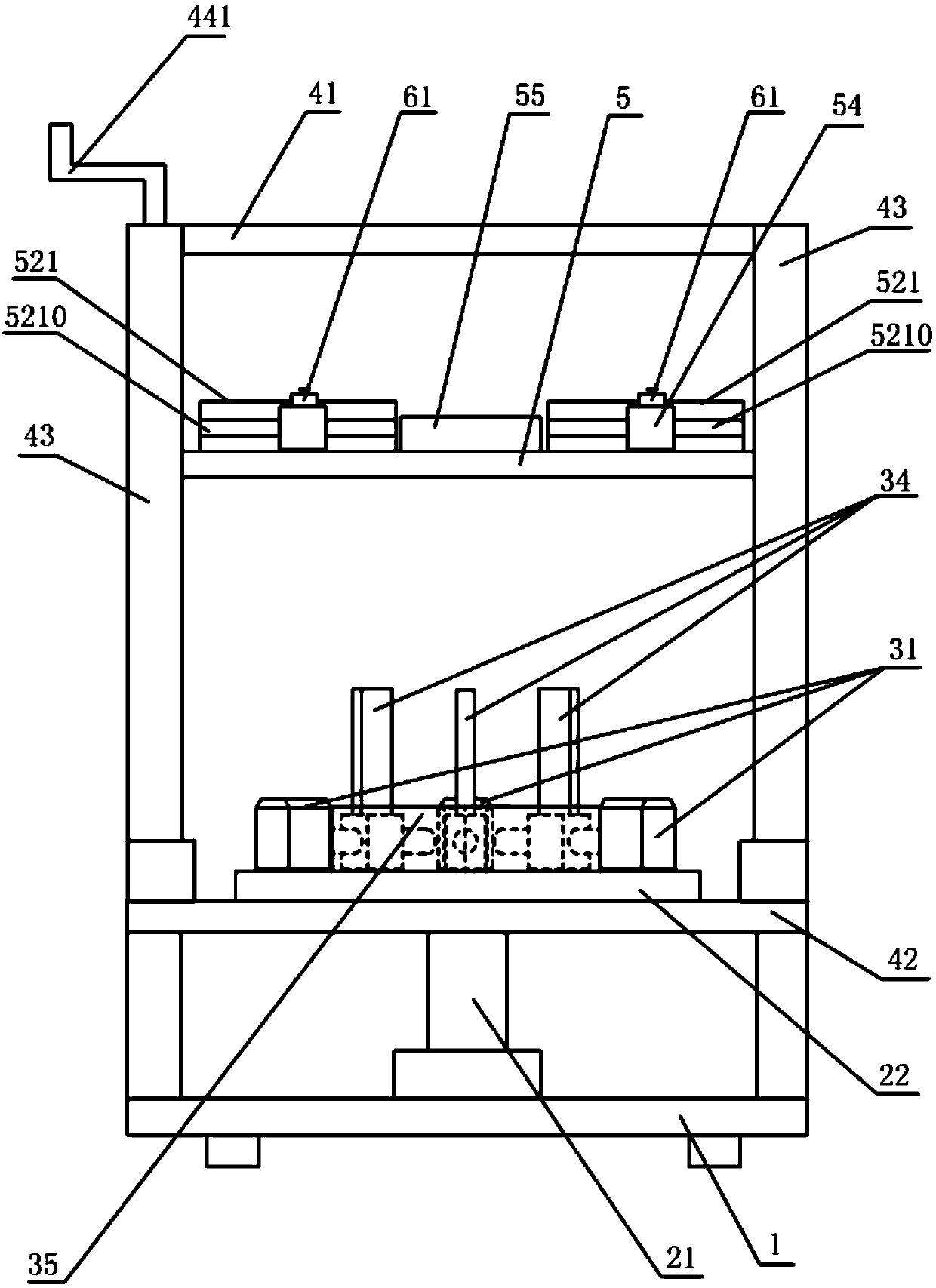

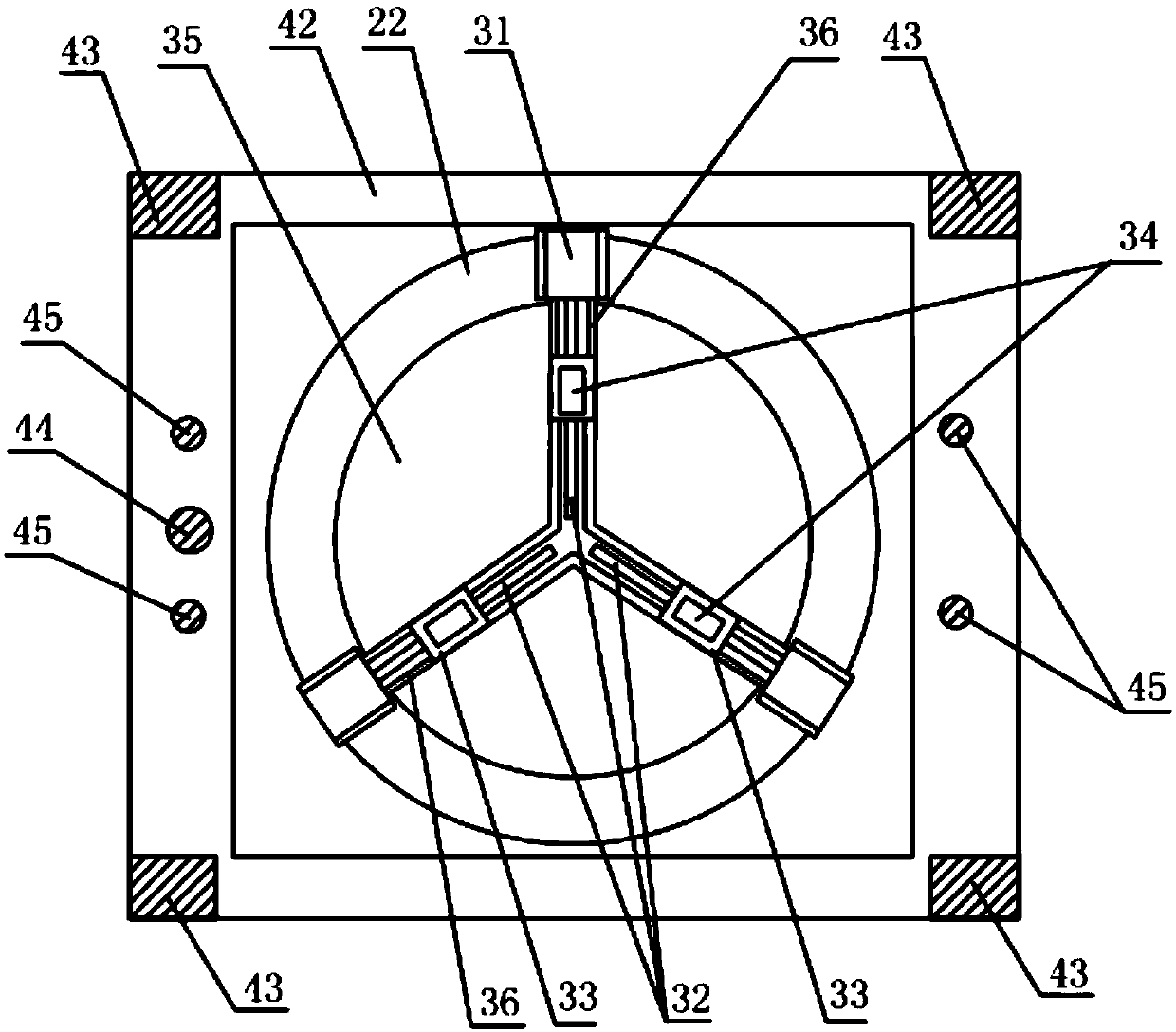

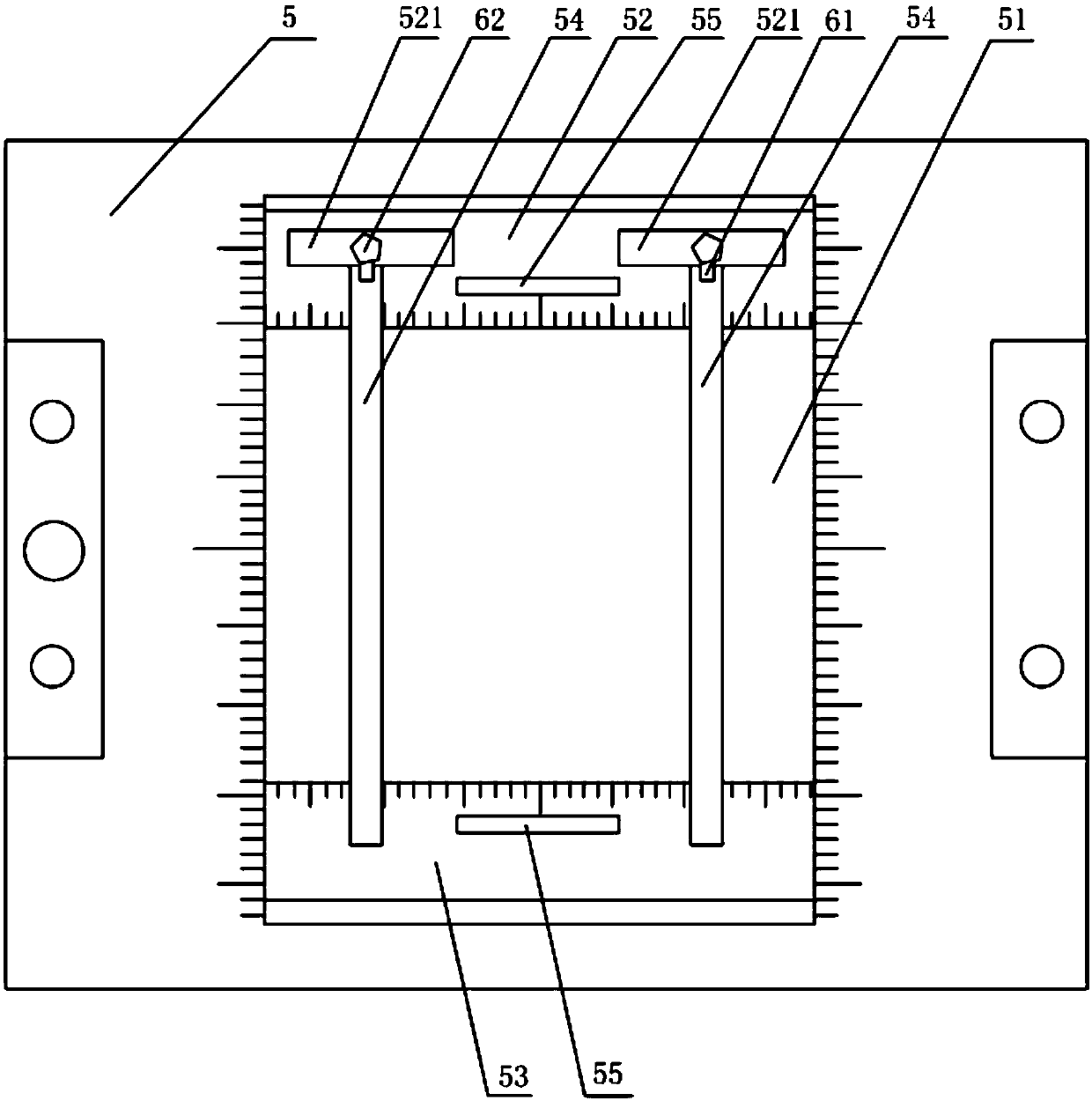

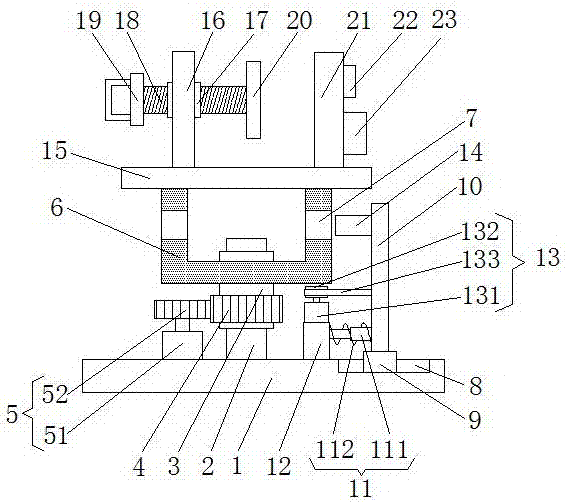

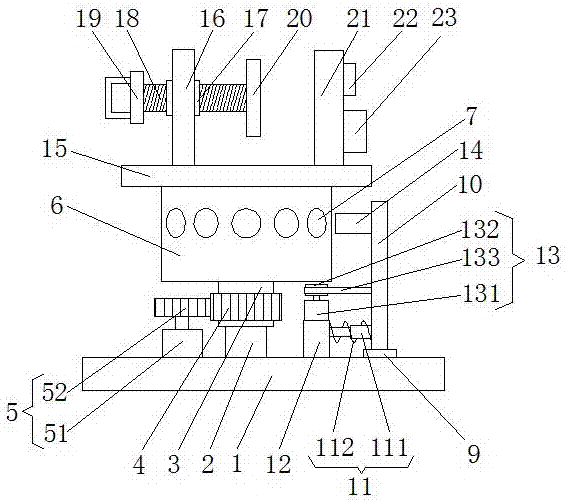

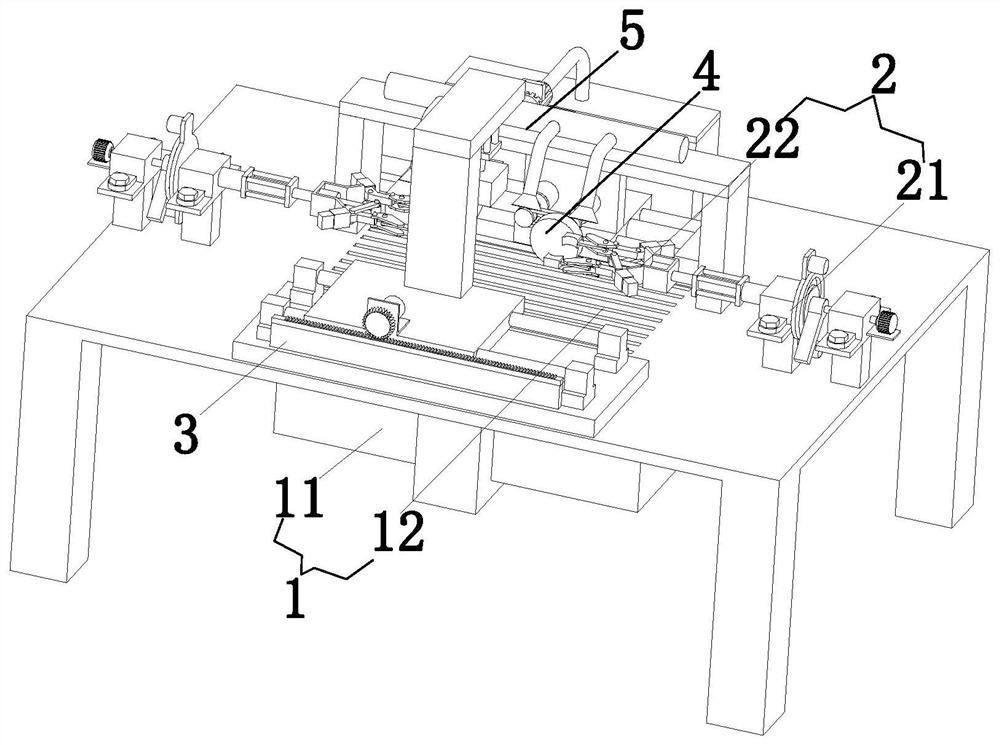

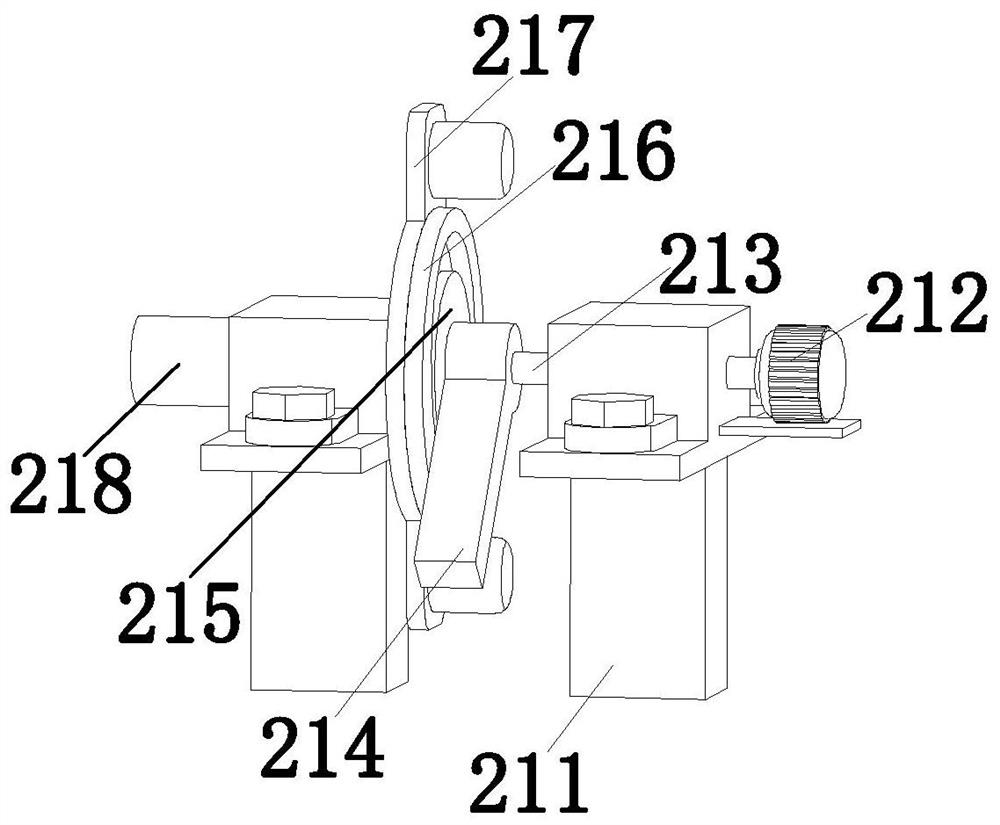

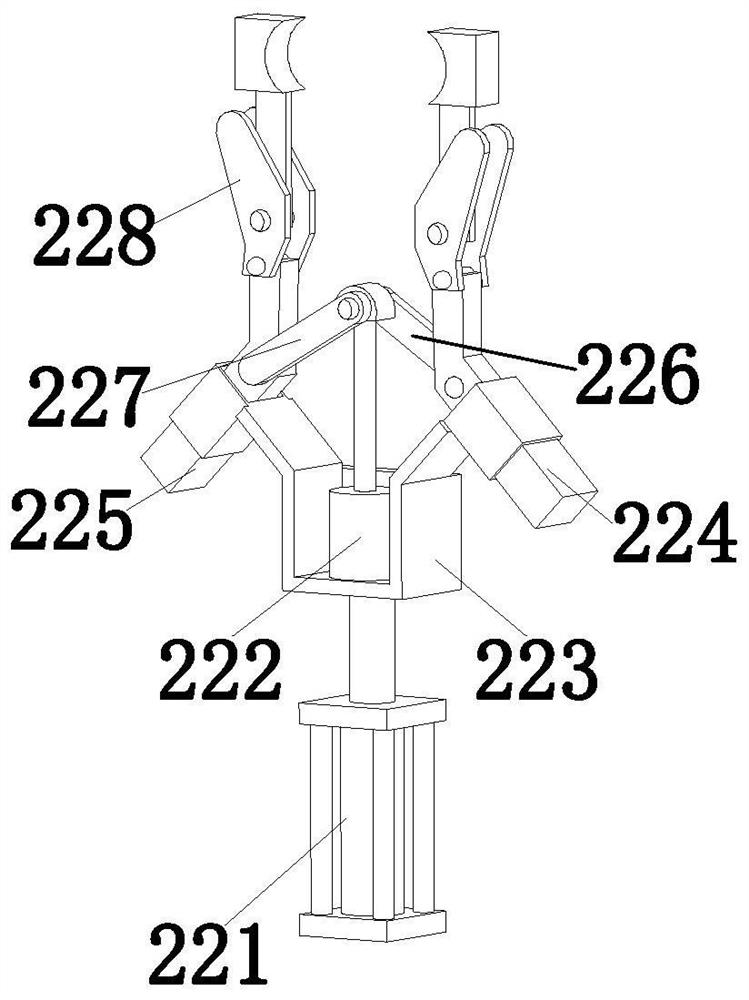

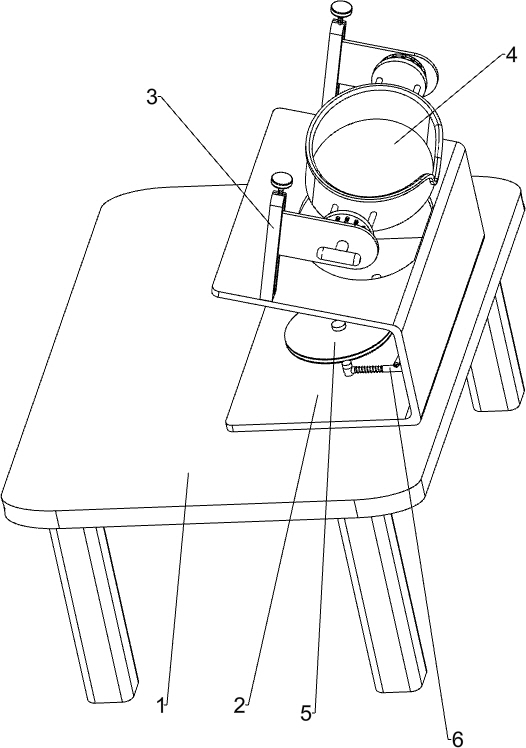

Pipeline flange welding positioning tool

PendingCN109604925AReduce in quantityReduce usageWelding/cutting auxillary devicesAuxillary welding devicesVertical alignmentEngineering

The invention belongs to the technical field of welding clamps, and particularly relates to a pipeline flange welding positioning tool. According to the positioning tool, motors are used for controlling first lead screws synchronously so as to further control the position adjusting of three vertical pipeline positioning columns, so that the tool can adapt to positioning of pipelines with differentdiameters, the center of a flange is adjusted to be overlapped with a central axis of each pipeline positioning column through a flange center adjusting assembly, the flange is placed at the top endof a pipeline through a second lead screw, and the good vertical alignment of the flange and the pipeline is realized; compared with the prior art, the positioning tool can meet the positioning of more pipeline flanges with different sizes, and the use number of the positioning tool is reduced; the flange and the pipeline which are aligned primarily are subjected to three-point fixation by spot welding, then a flange bearing plate is moved away by rotating the second lead screw, a pipeline bearing plate is rotated horizontally to carry out one-circle welding at a joint, a welding device does not need to move in the welding process, the operation is convenient, and time and labor are saved.

Owner:QINGDAO HUANGHAI UNIV

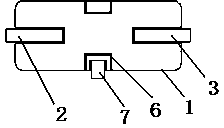

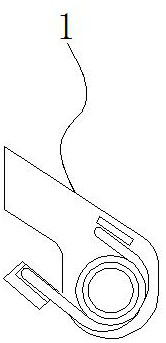

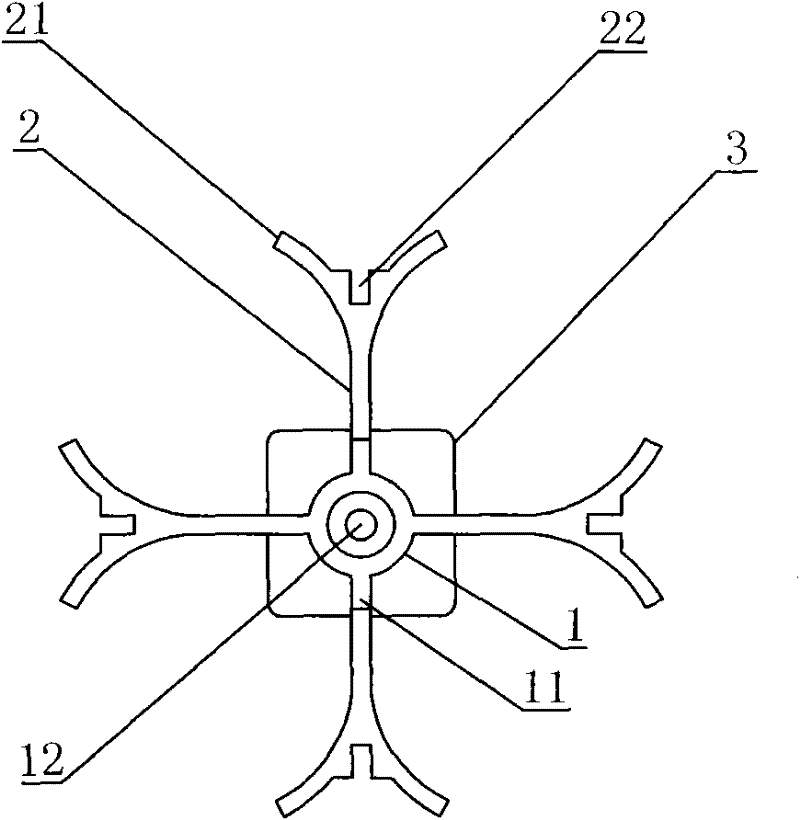

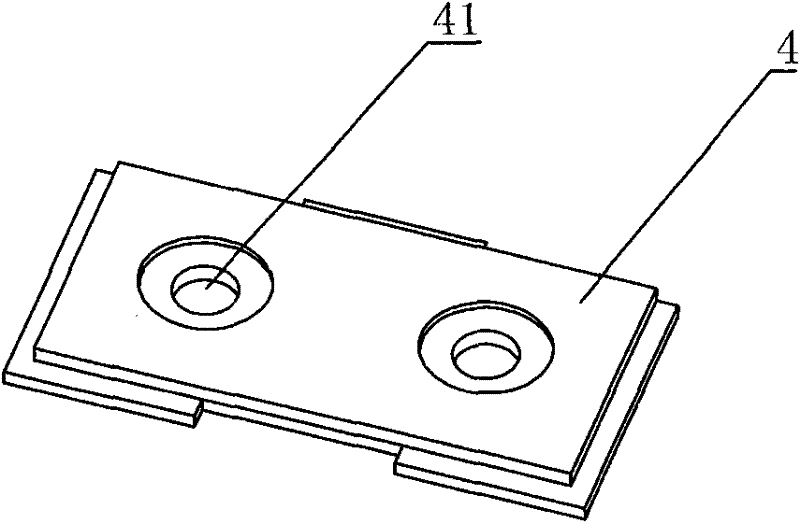

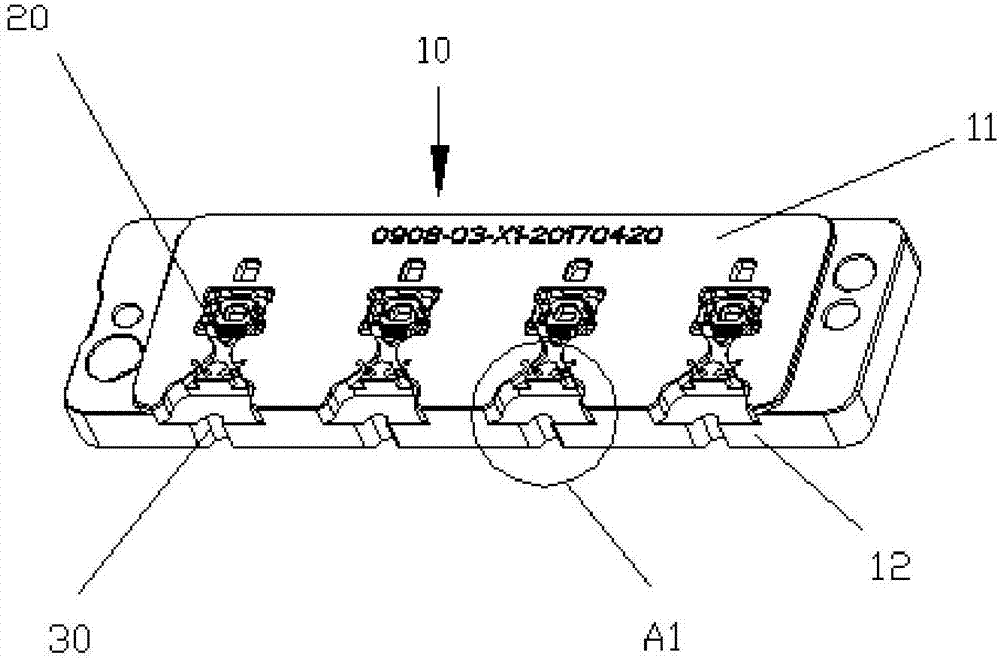

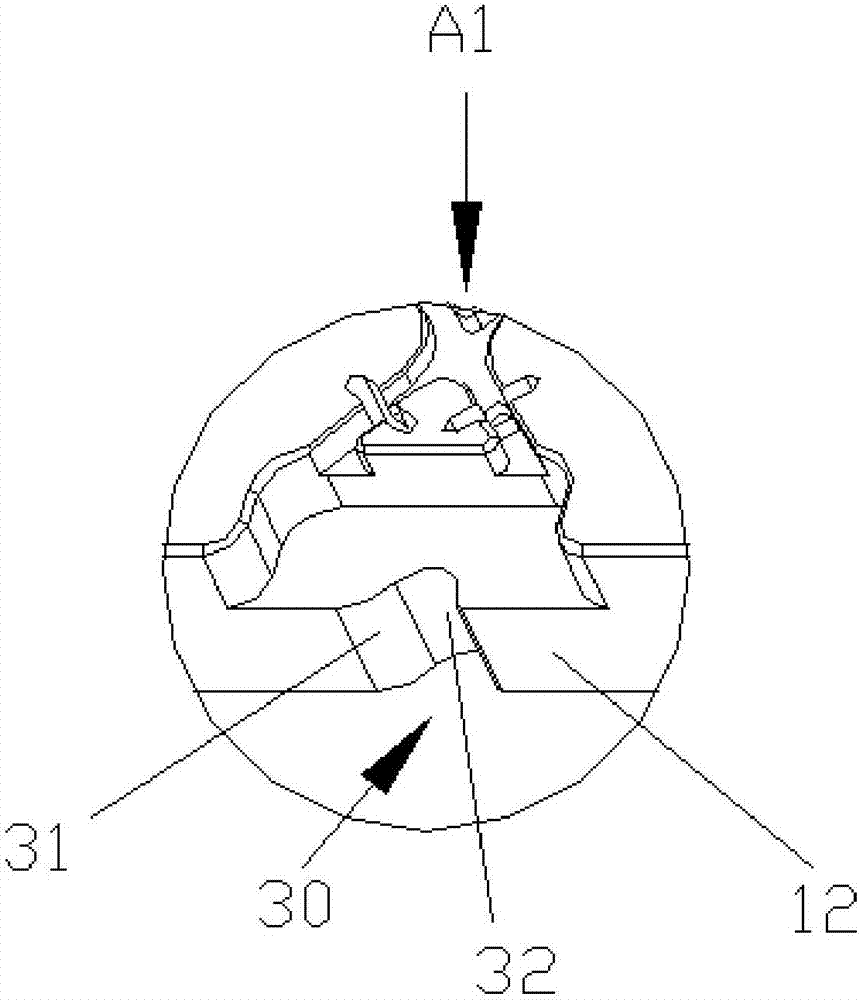

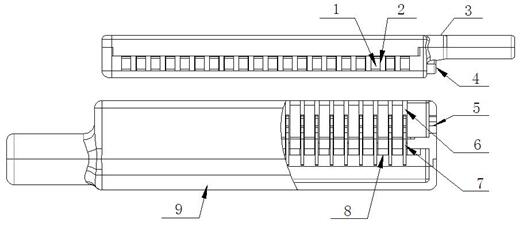

Metal sheet grounding three lead surface mount quartz resonator and production technology thereof

ActiveCN104753495AConvenient spot weldingConvenient tin wrappingImpedence networksSurface mountingMetal sheet

The invention relates to the field of electron components, in particular to a metal sheet grounding three lead surface mount quartz resonator and a production technology thereof. A third lead of the metal sheet grounding three lead surface mount quartz resonator is a metal sheet. The production technology of the metal sheet grounding three lead surface mount quartz resonator specially includes following steps: manufacturing a metal sheet material part; manufacturing an insulating spacer; performing lettering processing; placing the metal sheet material part and the insulating spacer in a disk for a test and a marking; fixing the metal sheet; cutting off the metal sheet. According to the metal sheet grounding three lead surface mount quartz resonator, the metal sheet is used as the third lead, and spot welding and tin wrapping on a circuit board are facilitated. Due to the fact that the metal sheet is welded in spot mode after the spacer is inserted, repeated disk stacking operations are saved, the phenomenon that the third lead is disconnected during the spacer insertion process and the use process of a client is avoided, and production efficiency and qualified rate of products are improved. Additionally, the production technology of the metal sheet grounding three lead surface mount quartz resonator can achieve automatic processing.

Owner:MDH TECH CO LTD

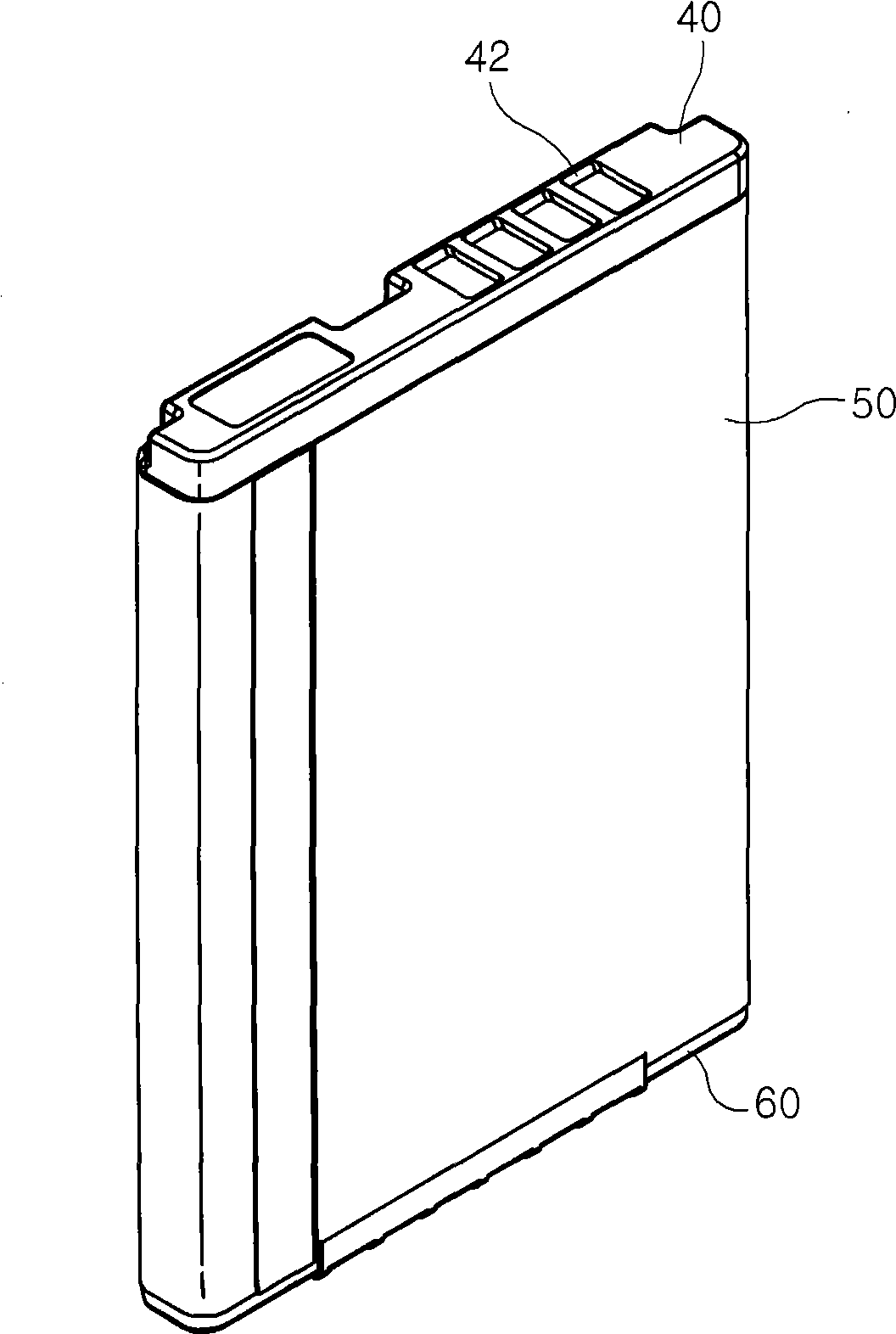

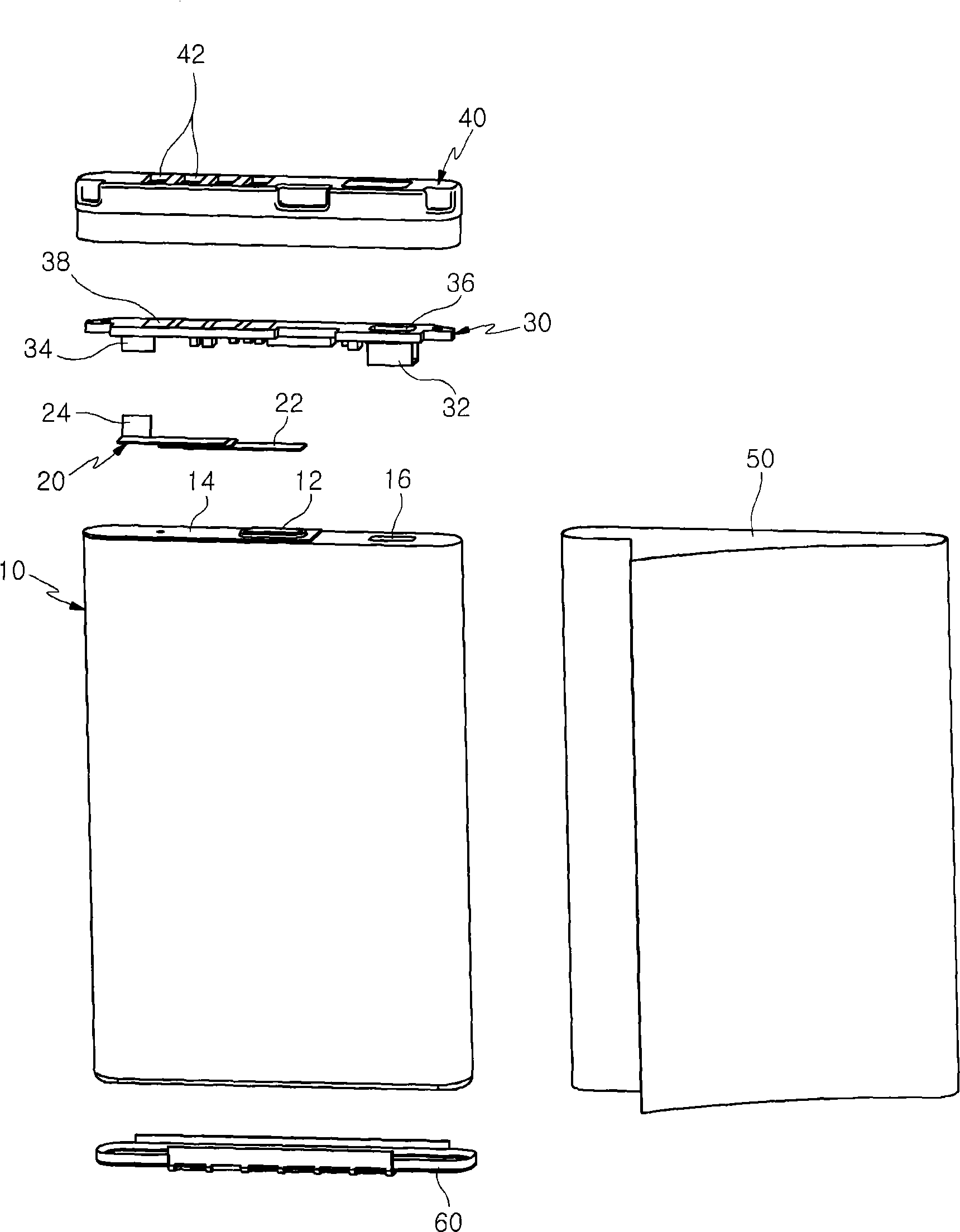

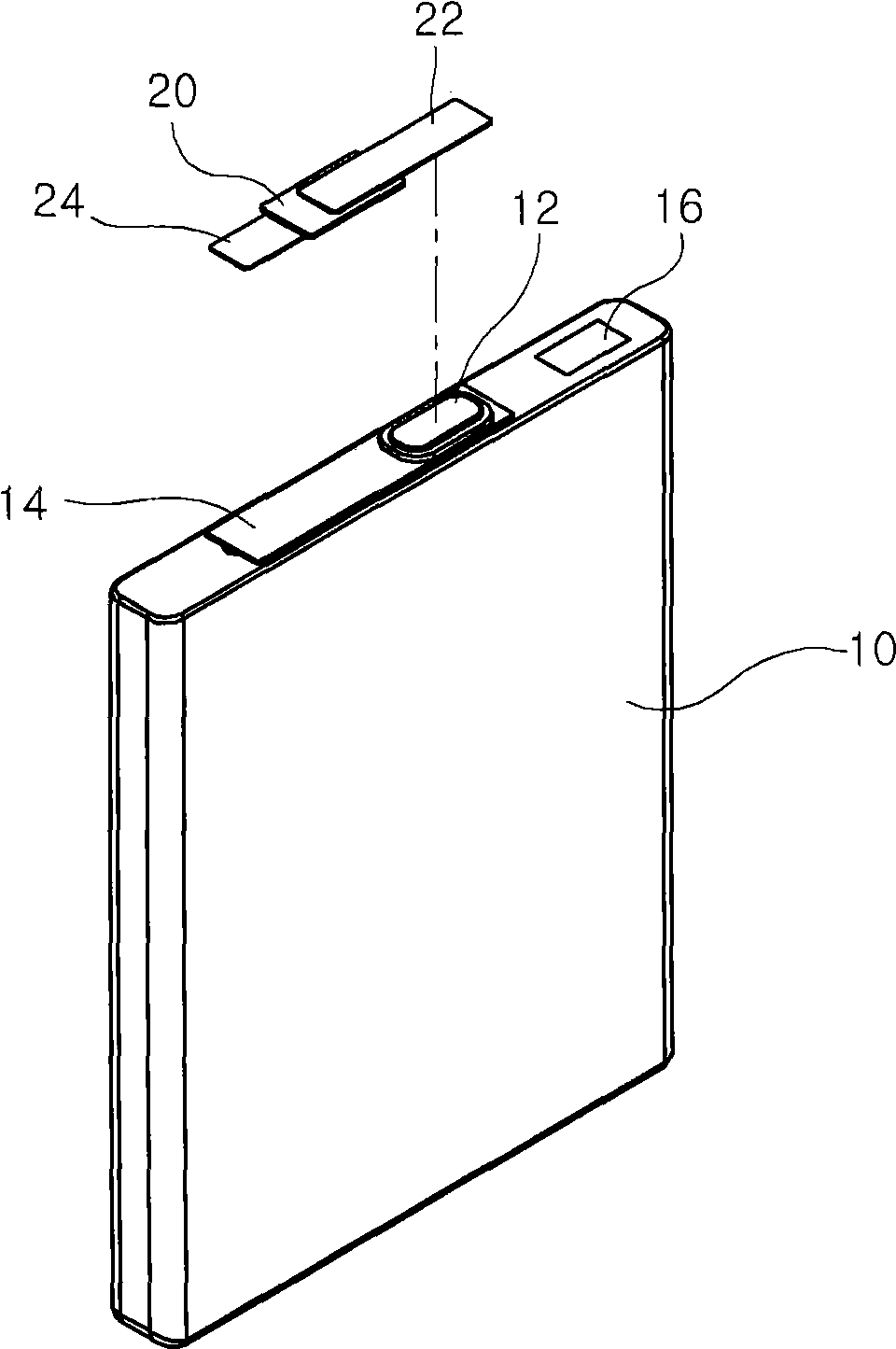

Built-in battery pack for mobile communication terminal and method of manufacturing the same

InactiveCN101533897ASimple processReduce the number of partsBatteries circuit arrangementsCell component detailsSolderingExternal connection

The invention relates to a built-in battery pack for mobile communication terminal and a method of manufacturing the same; for the anode / cathode terminal of the battery pack, the invention does not soldering but uses precise spot welding mode to weld the anode / cathode nickel sheets of PCM and one side connecting portion of PTC, which simplifies the product structure and operating procedures and reduces the badness caused by soldering. The battery pack comprises a battery unit formed with an anode terminal and a cathode terminal at the upper side for charging and discharging; PTC, when mounting, one side connecting portion of bimetal function located at the upper part of the cathode terminal of the battery pack; PCM, the anode and cathode nickel sheets provided at the lower side by surface assemble in raised manner and spot welded one the other side connecting portion of the PTC and the anode terminal of the battery pack formed with corresponding spot welding holes on the upper side; a top cover combined in the upper side of the battery pack and penetrated with corresponding external connecting hole for exposing the external connecting terminal formed on the upper side of the PCM; a bottom cover combined in the lower side of the battery unit; a packing label for packing the battery pack.

Owner:BETESH ENERGY

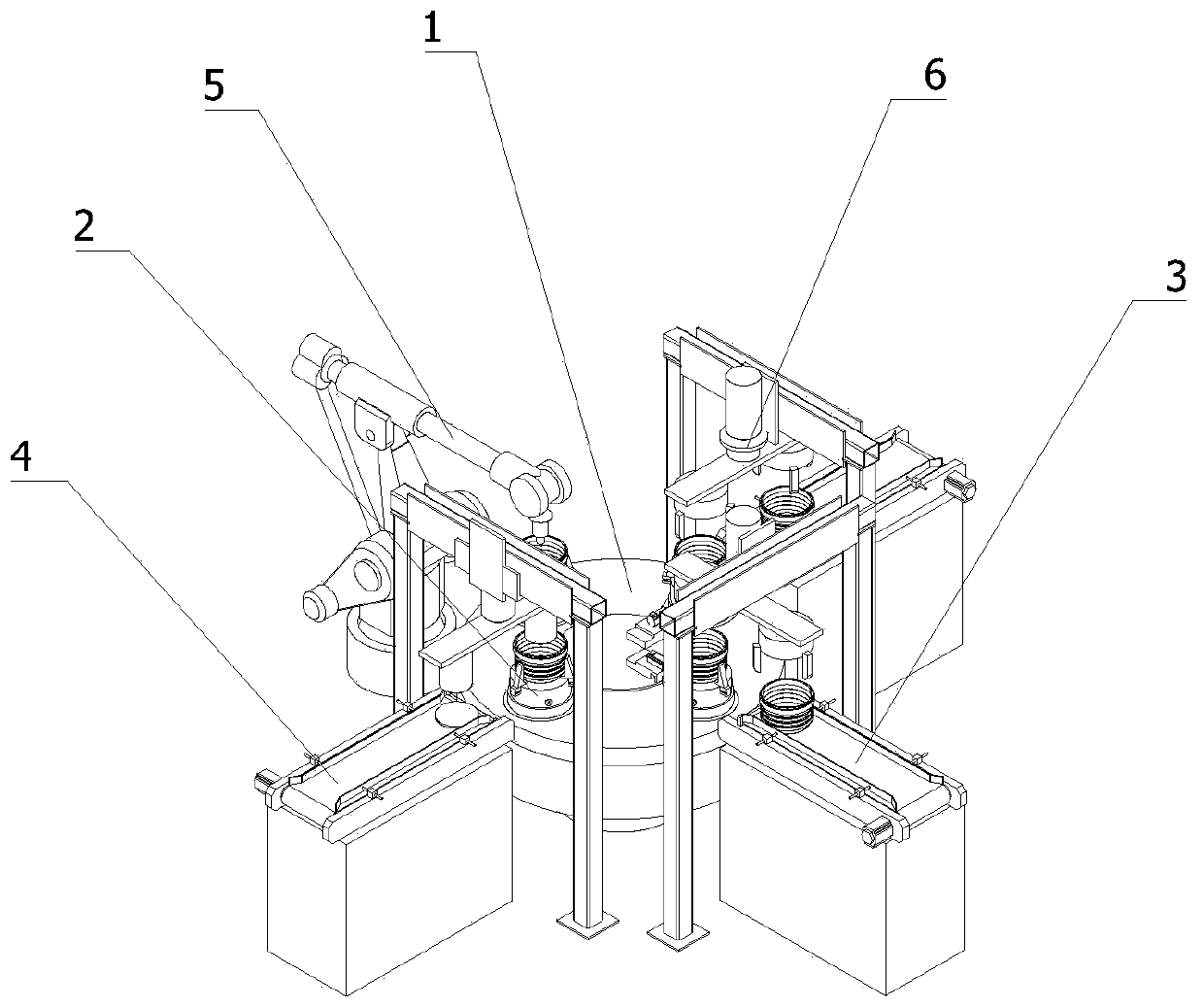

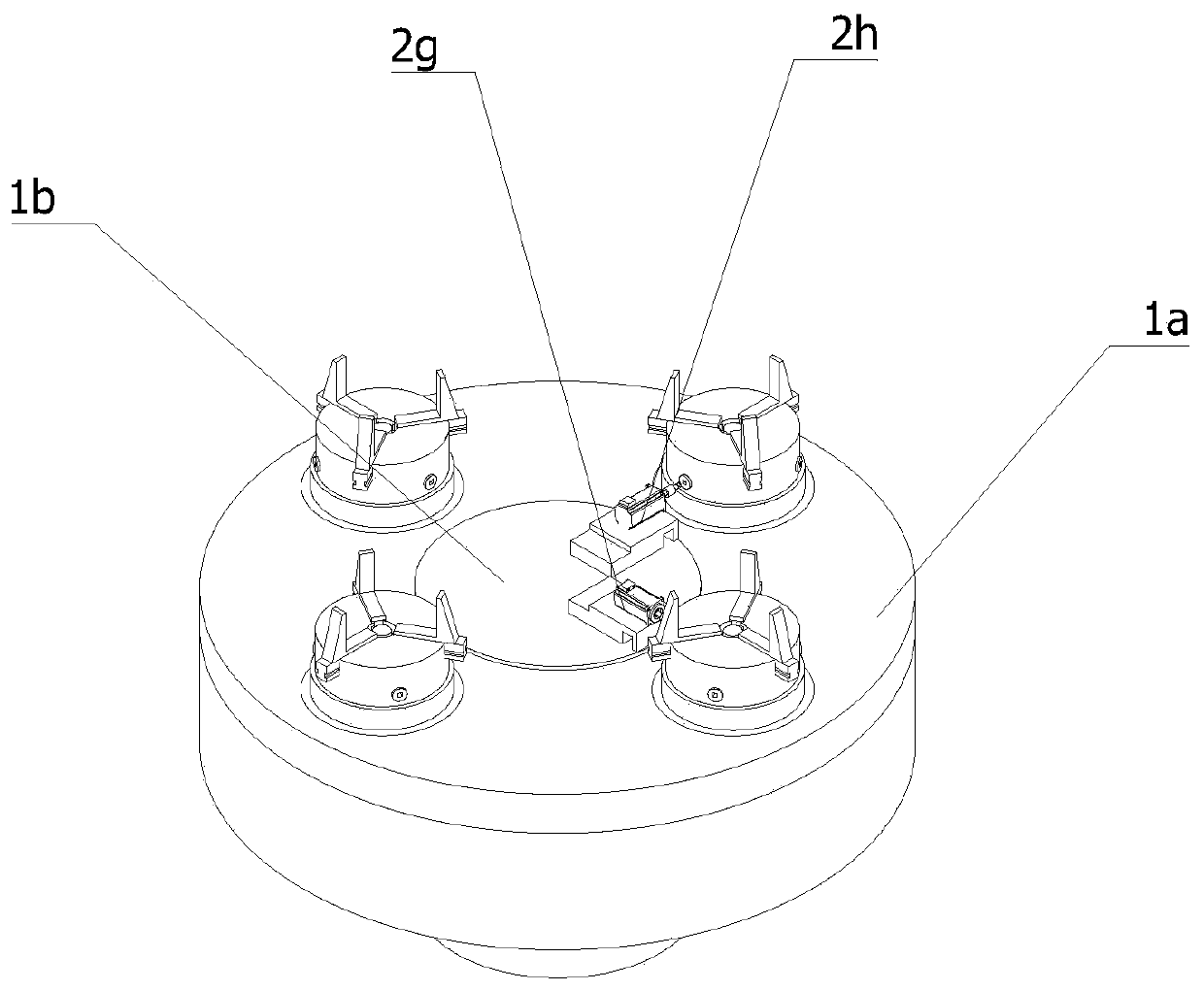

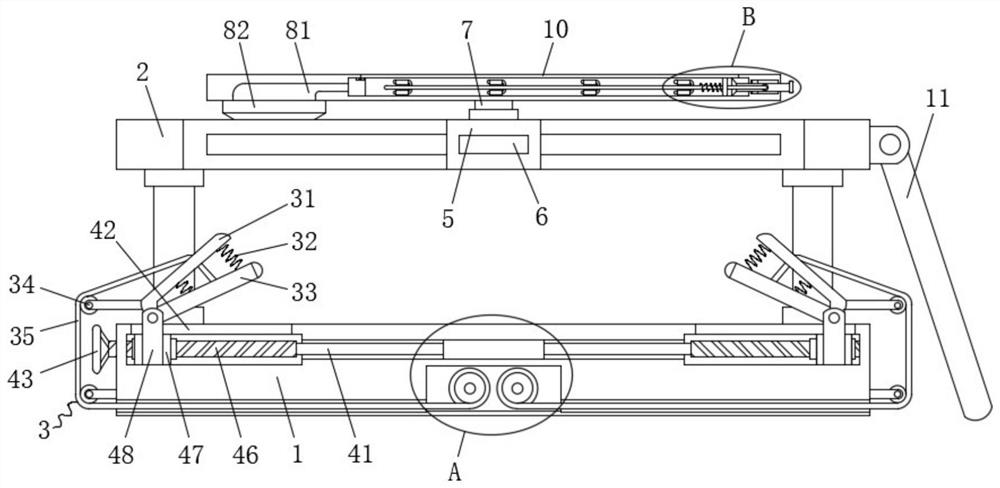

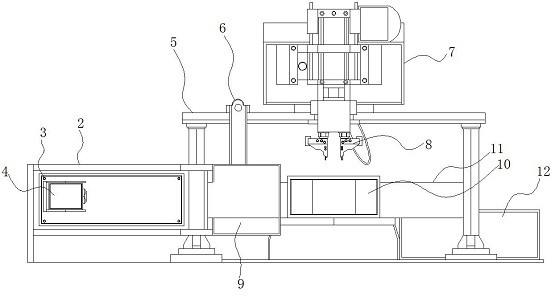

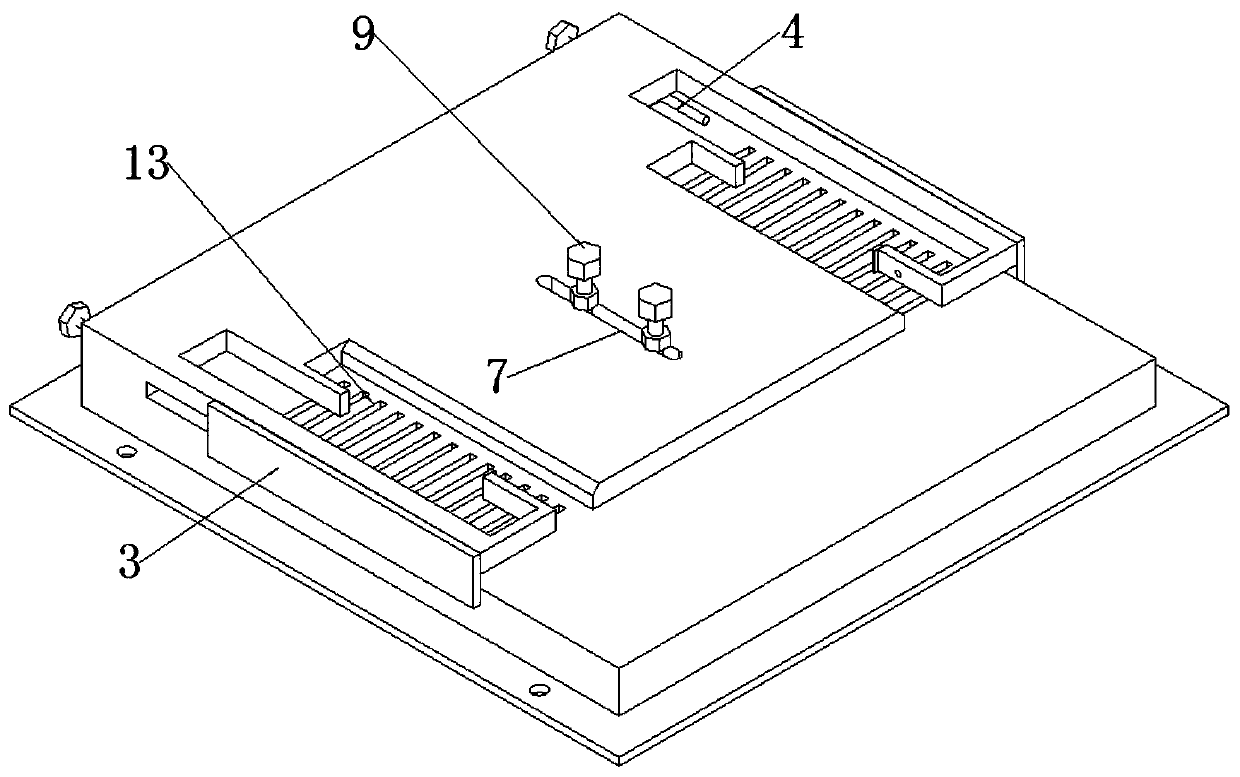

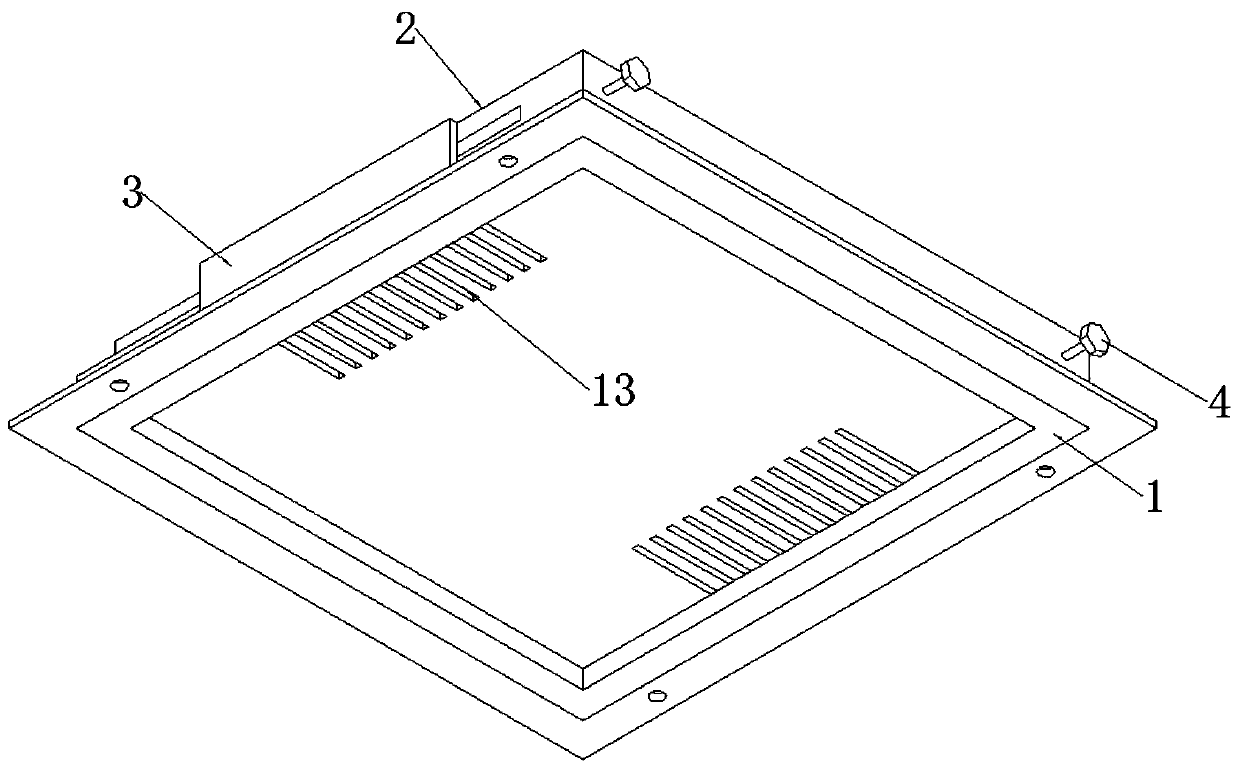

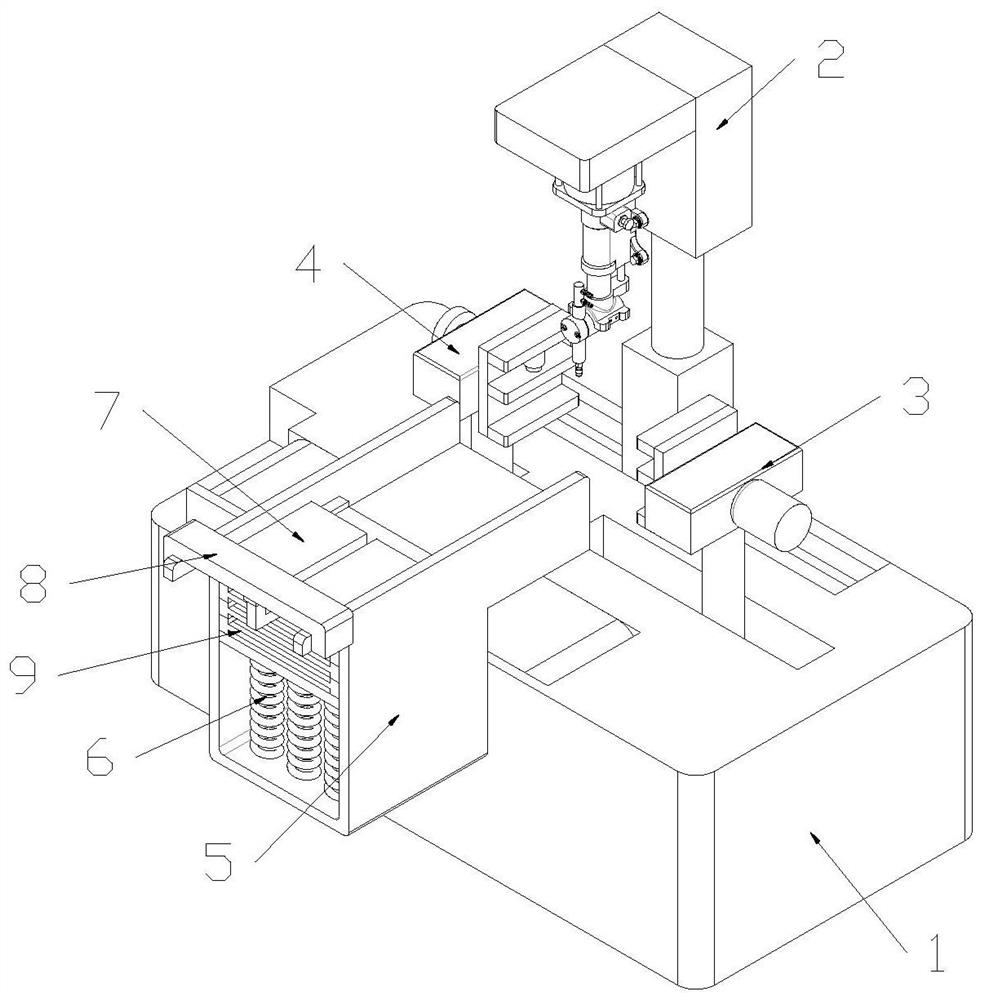

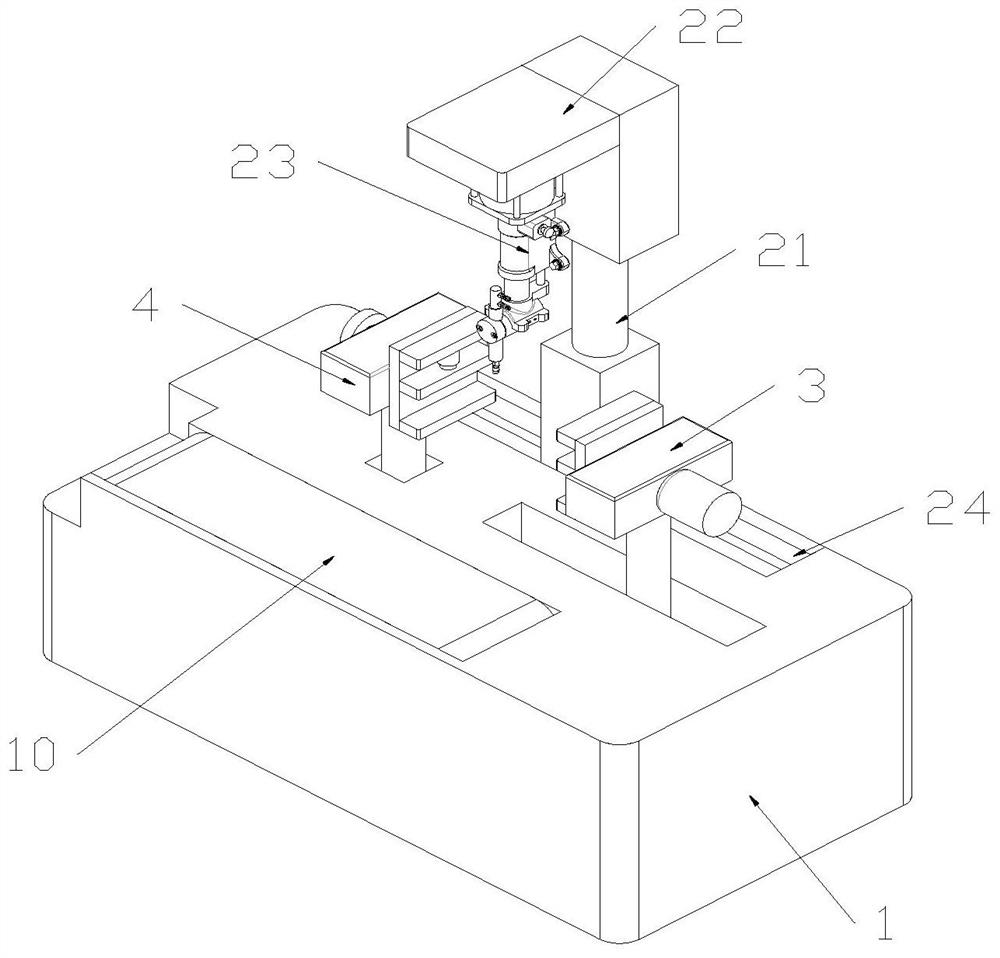

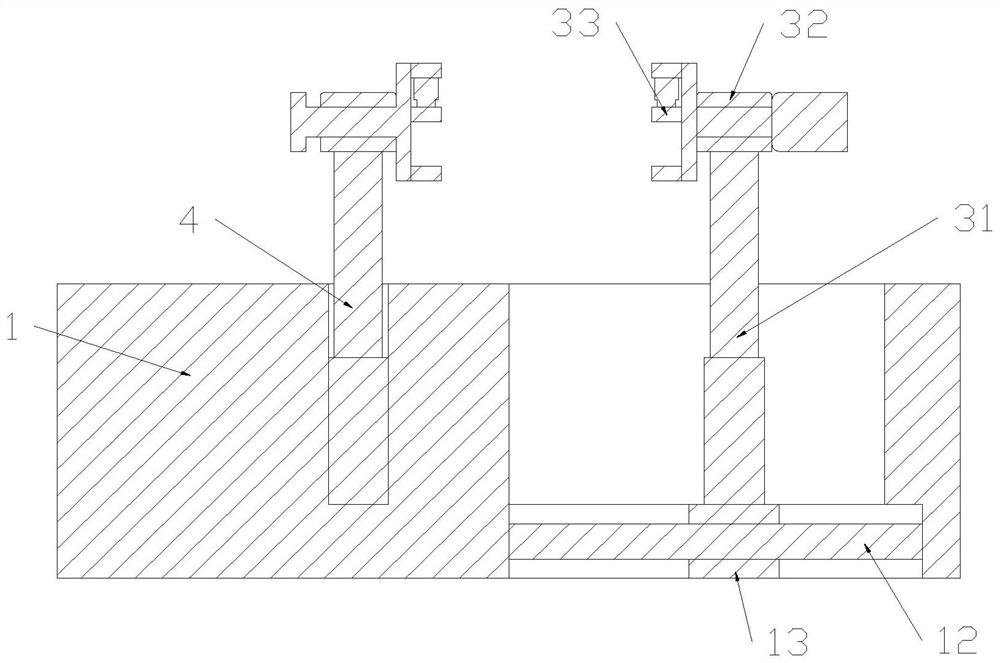

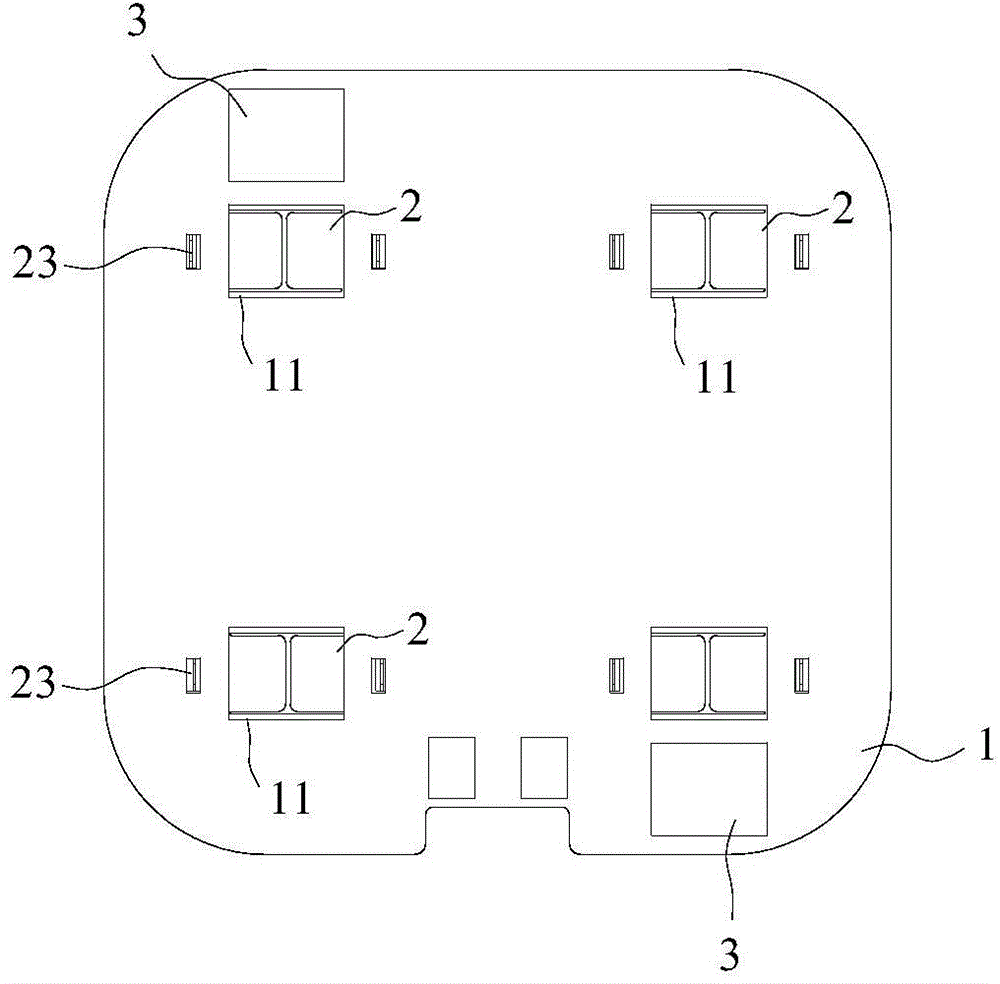

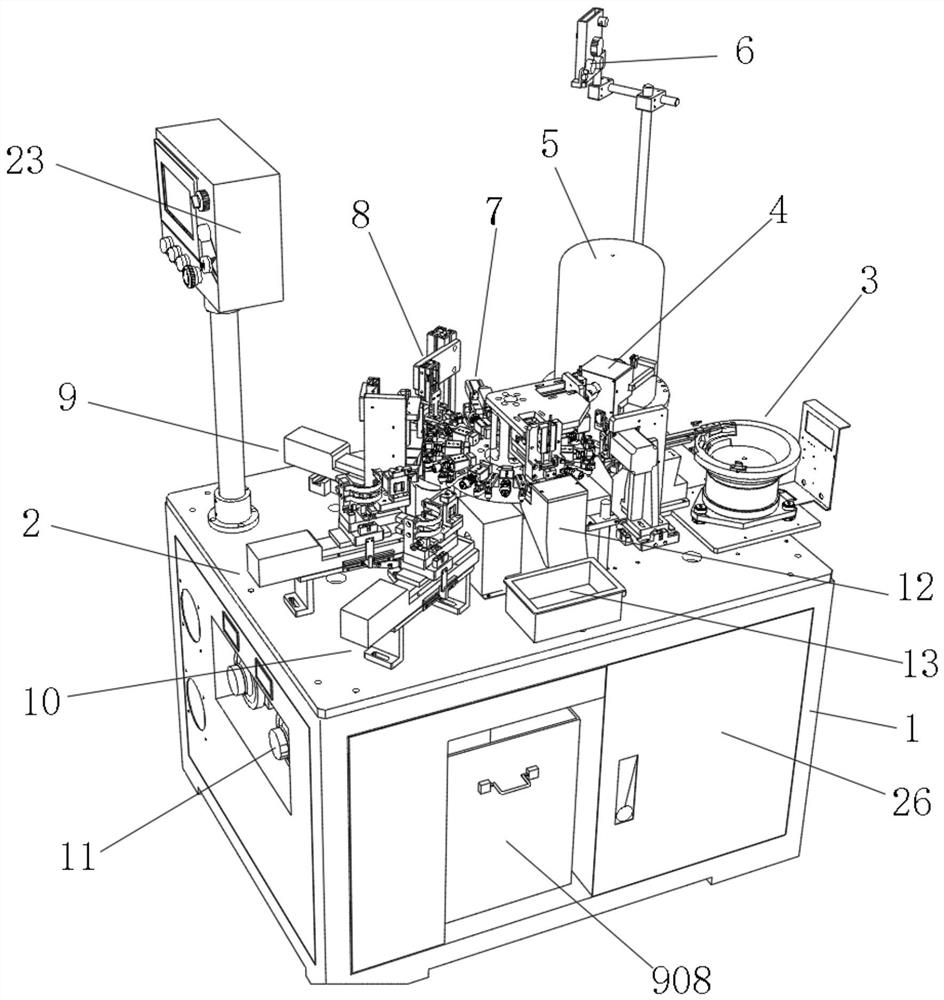

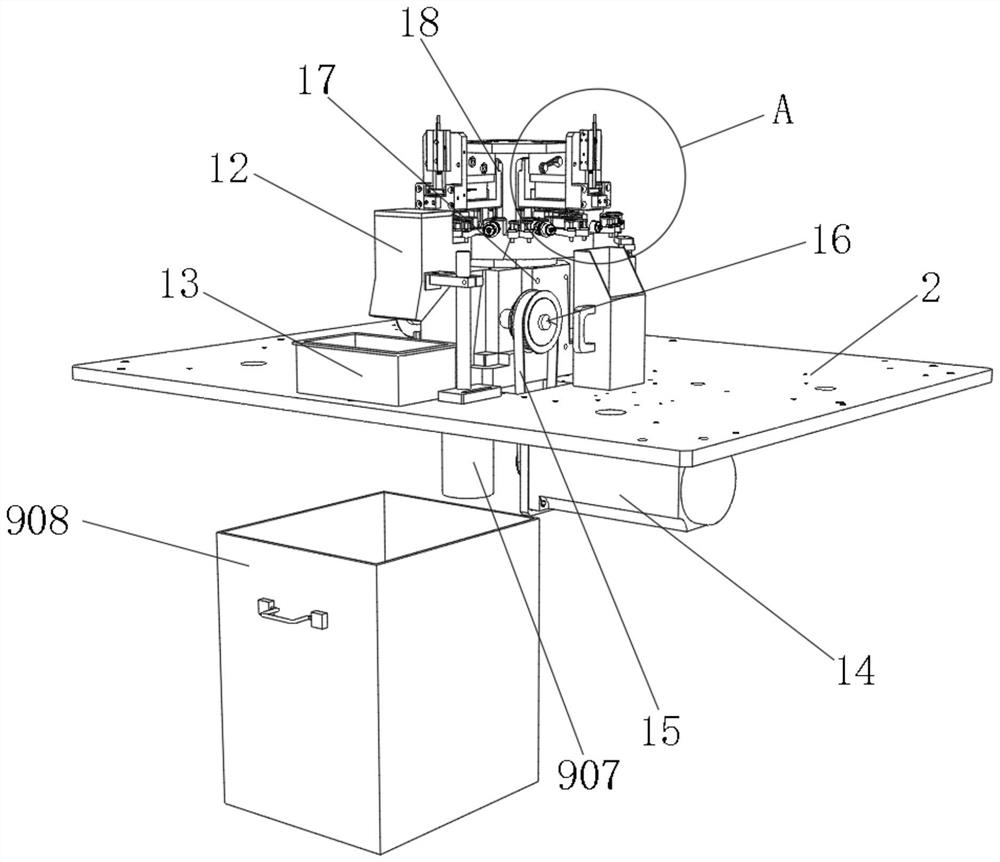

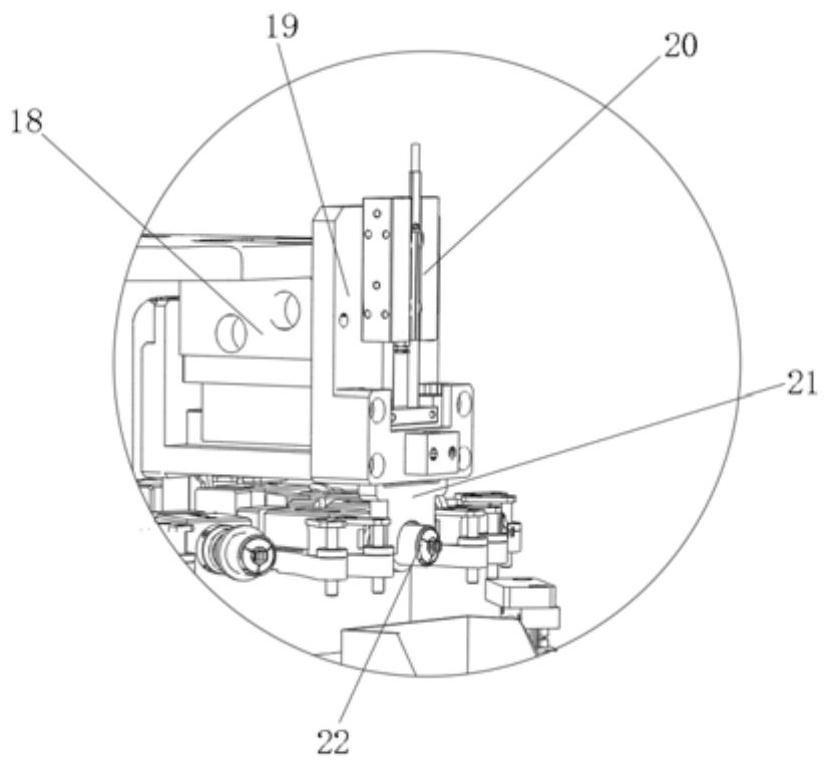

Automatic mounting spot welding machine for separation plate of drum brake

ActiveCN111168216AEasy to fall intoEasy to get stuckWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention relates to the field spot welding production, in particular to an automatic mounting spot welding machine for a separation plate of a drum brake. The automatic mounting spot welding machine comprises an operation table, drum brake clamps, a drum brake feeding mechanism, a separation plate feeding mechanism, a spot welding mechanism and a finished product unloading mechanism. The operation table comprises a hollow rotary disc and a fixed disc, and the hollow rotary disc is coaxially and rotationally arranged on the fixed disc. The drum brake clamps are rotationally and evenly distributed on the fixed disc at four stations in the axial direction, and the drum brake feeding mechanism, the separation plate feeding mechanism, the spot welding mechanism and the finished product unloading mechanism are sequentially arranged on one sides of the four stations of the hollow rotary disc. According to the device, automatic feeding and welding can be carried out on the drum brake andthe separation plate, the work efficiency is high, and the labor cost is reduced.

Owner:FARINA JINAN WELDTEC & MACHINERY

Spot welding assisting device for overall automobile manufacturing

ActiveCN107570950AConvenient spot weldingShorten the timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a spot welding assisting device for overall automobile manufacturing. The spot welding assisting device comprises a bottom plate, wherein a rotating shaft is fixedly connectedwith the upper surface of the bottom plate; the surface of the rotating shaft is sleeved by a bearing; the bearing is connected with the lower surface of the shell in a clamped manner; the surface ofthe bearing is connected with a driven gear in a sleeved manner; the driven gear is positioned below the shell; the driven gear is meshed with a first driving device; the lower surface of the first driving device is fixedly connected with the upper surface of the bottom plate. According to the spot welding assisting device for overall automobile manufacturing, a driving gear is driven to rotate bythe output shaft of a first motor in a rotation manner, the driving gear is rotated to drive the driven gear to rotate, then the shell is driven to rotate, then a workpiece above a support plate is driven to rotate, spot welding in different positions on the worpiece is carried out conveniently by operators, the positions of an electronic welding machine and the workpiece do not need to be changed by the operators when spot welding is carried out, the time and the labor of the operators are saved, and convenience is brought to the operators when the workpiece is subjected to spot welding.

Owner:上海翌鲲汽车装备有限公司

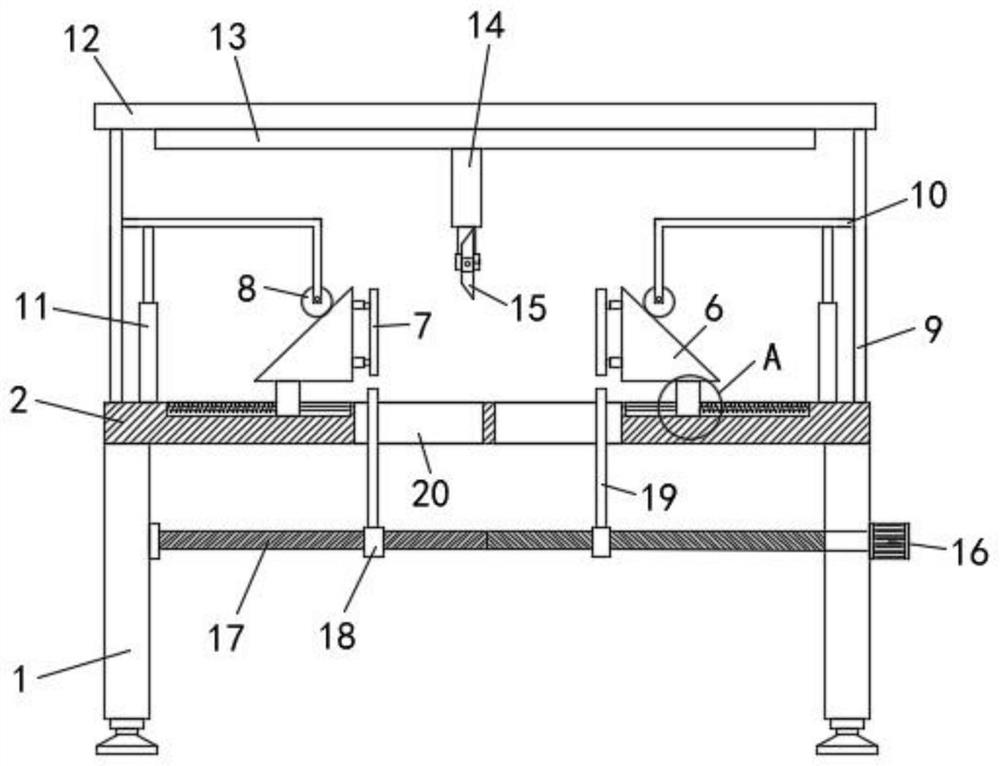

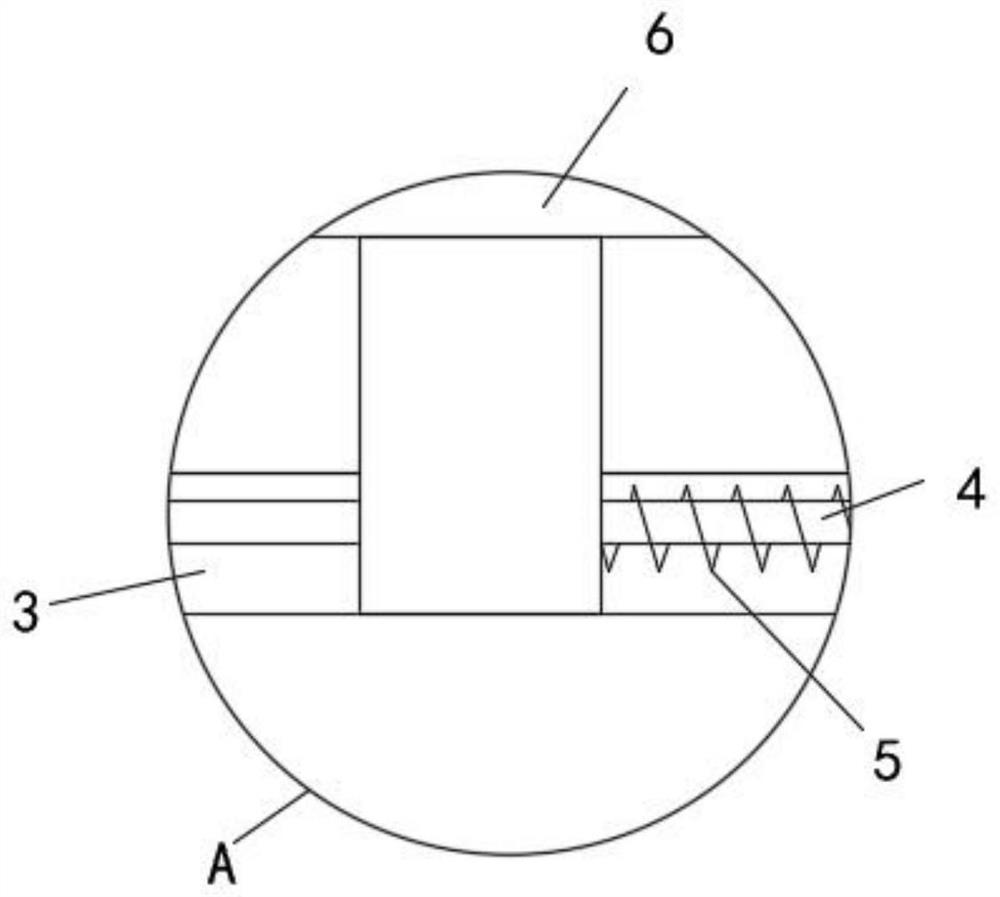

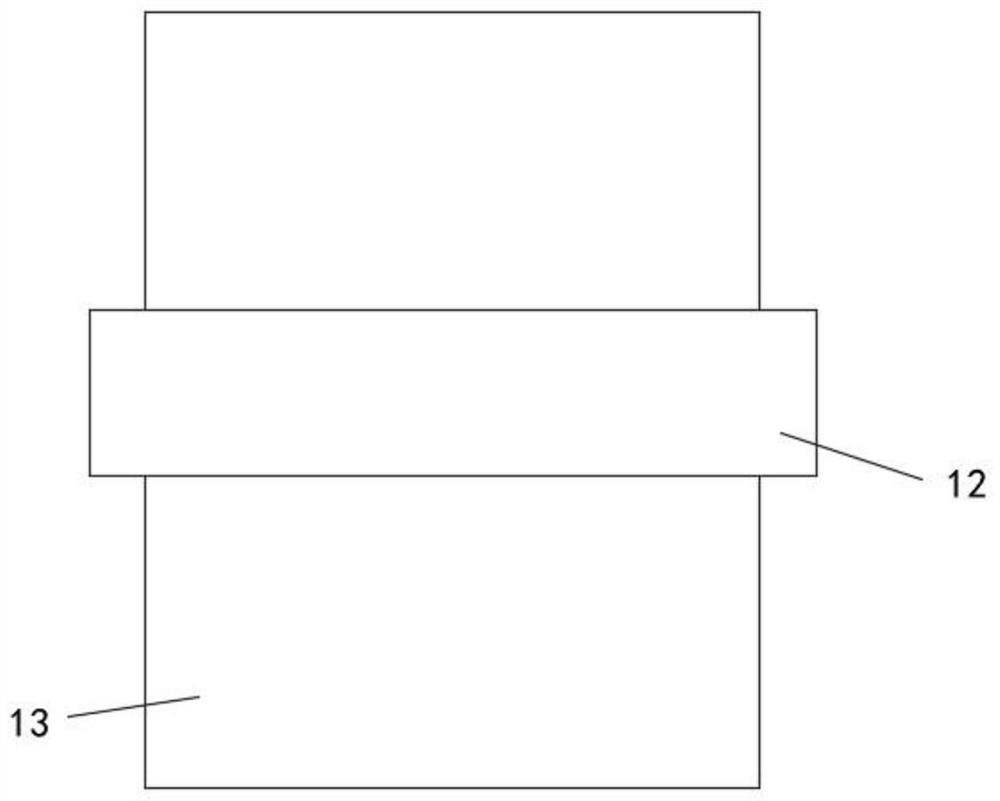

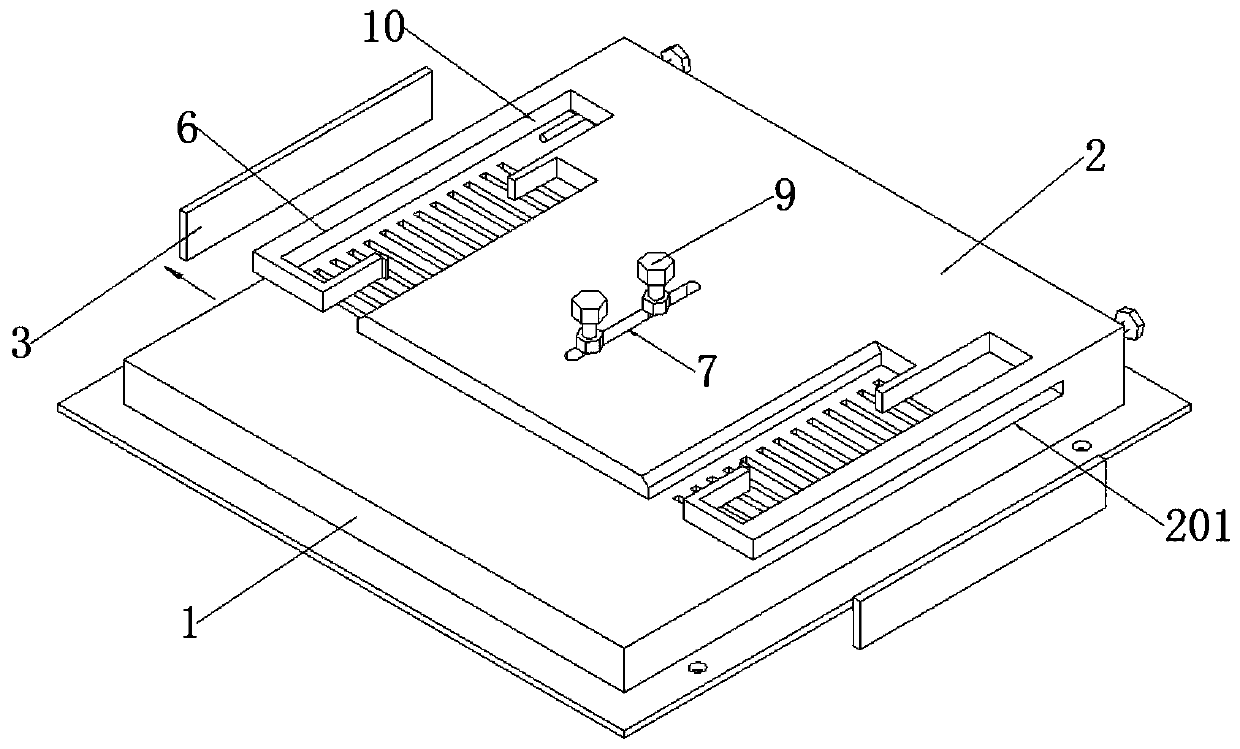

Adjustable automobile repair spot welding workbench with clamping mechanism

InactiveCN113084320AReach positioning functionRealize the clamping effectDispersed particle filtrationWelding/cutting auxillary devicesGear wheelElectric machinery

The invention discloses an adjustable automobile repair spot welding workbench with a clamping mechanism, and belongs to the technical field of automobile repair spot welding. The adjustable automobile repair spot welding workbench comprises a workbench body and a top plate, the four corners of the upper surface of the workbench body are fixedly connected to the lower surface of the top plate through supporting columns, the clamping mechanism is arranged on the workbench body, the left side face and the right side face of the clamping mechanism are fixedly connected with the two ends of the clamping mechanism correspondingly, the clamping mechanism is located in the workbench body, and an adjusting mechanism is arranged in the workbench body. According to the adjustable automobile repair spot welding workbench, by arranging the clamping mechanism, when a motor works, first gears can be driven to rotate, two winding rollers can rotate reversely at the same time under the meshing action of the two first gears, the winding rollers can wind fixing ropes, two threaded columns are arranged to be opposite in thread and can rotate at the same time under the action of a first rotating shaft, threaded caps can drive a U-shaped plate to move and adjust the position of the U-shaped plate, so that two clamping plates can be close to or far away from each other, the function of positioning parts of different sizes is achieved, and work of people is facilitated.

Owner:杭州启毓日用百货有限公司

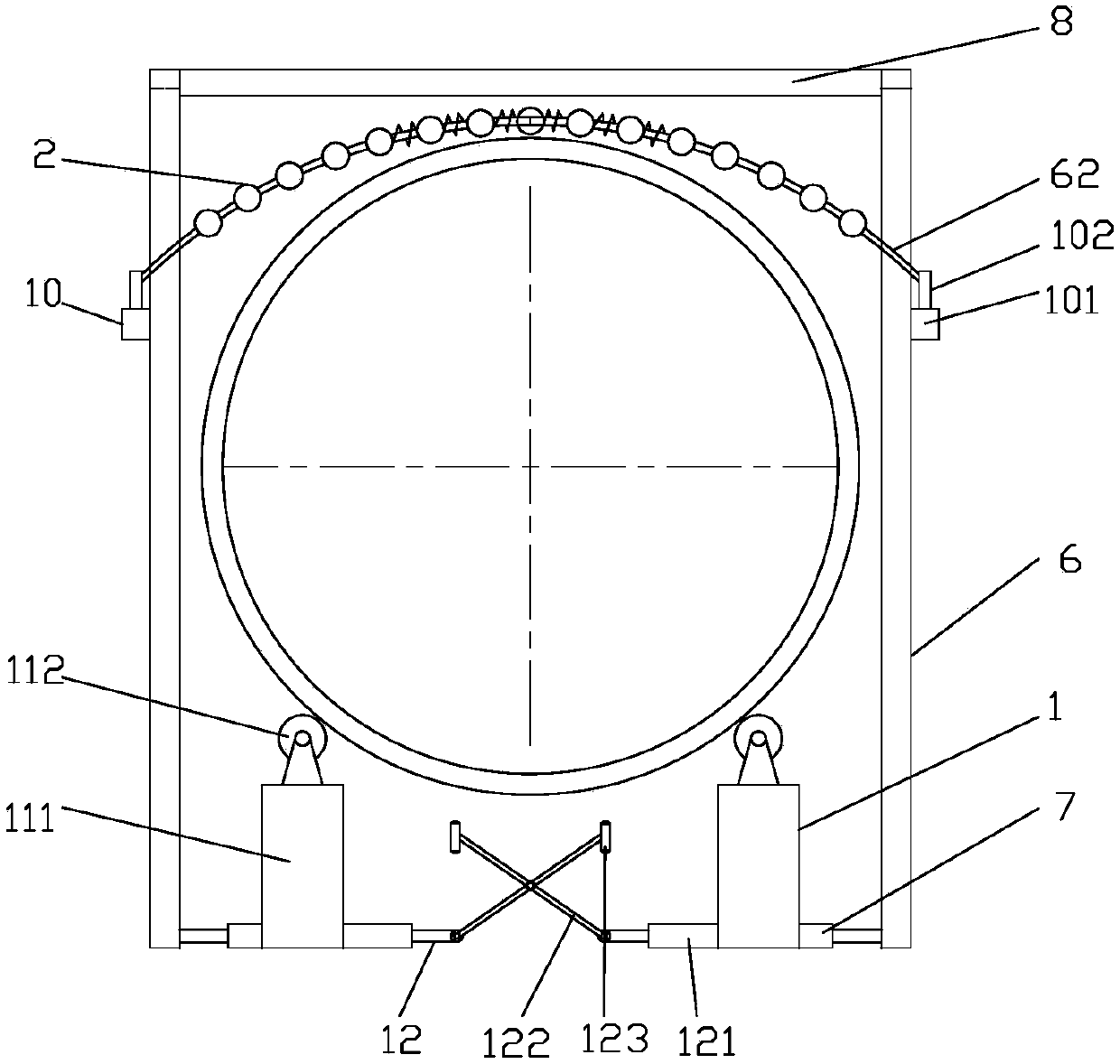

Auxiliary device for large-caliber steel cylinder butt joint

PendingCN107900603AConvenient spot weldingImprove reliabilityWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention discloses an auxiliary device for large-caliber steel cylinder butt joint, and relates to the field of steel cylinder machining, in particular to the auxiliary device for large-caliber steel cylinder butt joint. The auxiliary device for large-caliber steel cylinder butt joint is simple in structure and convenient to adjust and weld, and improves the machining quality. The auxiliary device for large-caliber steel cylinder butt joint comprises a pair of support sets and a pressing mechanism; and the pair of support sets are used for supporting a first steel cylinder and a second steel cylinder correspondingly. The auxiliary device realizes butt joint during sliding of the steel cylinders, achieves a reliable support effect, and improves the welding reliability.

Owner:JIANGSU JUXIN PETROLEUM STEEL PIPE

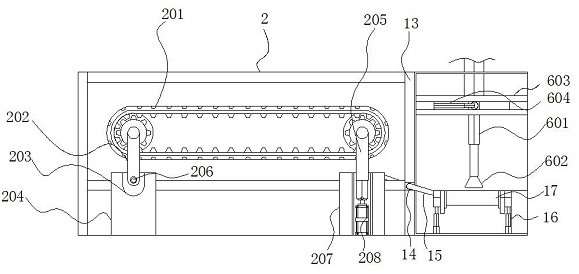

Multi-station full-automatic spot welding machine for tablet personal computer earphone machining

ActiveCN112171037AEasy to useFlexible adjustmentResistance electrode holdersMachine partsEngineering

The invention discloses a multi-station full-automatic spot welding machine for tablet personal computer earphone machining, and relates to the technical field of tablet personal computer earphone machining. The multi-station full-automatic spot welding machine comprises a machined part and a hydraulic air cylinder, a conveying device is arranged outside the machined part, and side plates are installed at the two ends of the outer portion of the conveying device. By arranging the conveying device, the machined part needing spot welding can be placed on a first conveying belt to be subjected tothe unified conveying treatment in a using process, meanwhile, the interaction of a right bottom block and an electric push rod and the mutual cooperation of a left supporting rod, a connecting block, a left bottom block, a right supporting rod and a connecting shaft can be utilized according to the actual using requirement to properly adjust the placing angle of the first conveying belt, so thatmore flexibility is achieved in an article conveying process, conveying guiding can be conducted through the gravity effect of the machined part when the first conveying belt cannot be used, manual operation of a user is not needed, and the user can use conveniently.

Owner:DONGGUAN UNIV OF TECH

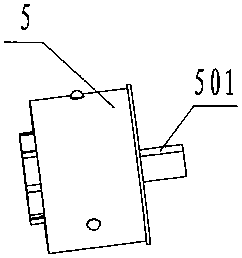

Fixing support of spot welding nickel sheet of mobile battery

ActiveCN110936083AConvenient spot weldingAvoid displacementWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryStructural engineering

The invention relates to a fixing support of a nickel sheet, in particular to a fixing support of a spot welding nickel sheet of a mobile battery. The technical purpose is to provide the fixing support of the spot welding nickel sheet of the mobile battery, and the fixing support provides convenience for spot welding of the nickel sheet of the battery and achieves precise spot welding. The fixingsupport of the spot welding nickel sheet of the mobile battery comprises a first clamping plate, cushion wheels, a battery fixing assembly, a battery positive electrode supporting assembly, a batterynegative electrode supporting assembly, a supporting fixing assembly and the like. The left and right sides of the top and bottom of the first clamping plate are provided with the cushion wheels, andthe rear side of the first clamping plate is provided with the battery fixing assembly for fixing the battery through a rotation mode. According to the fixing support, the battery fixing assembly canfix multiple batteries, in this way, the nickel sheet of the battery can be conveniently subjected to spot welding, and the fixing support can rotate at the same time. In this way, positive and negative electrodes of the battery can be quickly subjected to spot welding, and through a second slide groove and a slide block, the battery can be more stable during spot welding.

Owner:义乌市嘉诗电子科技有限公司

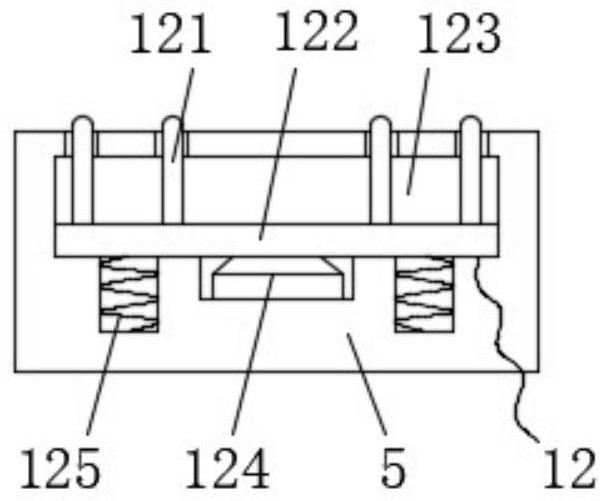

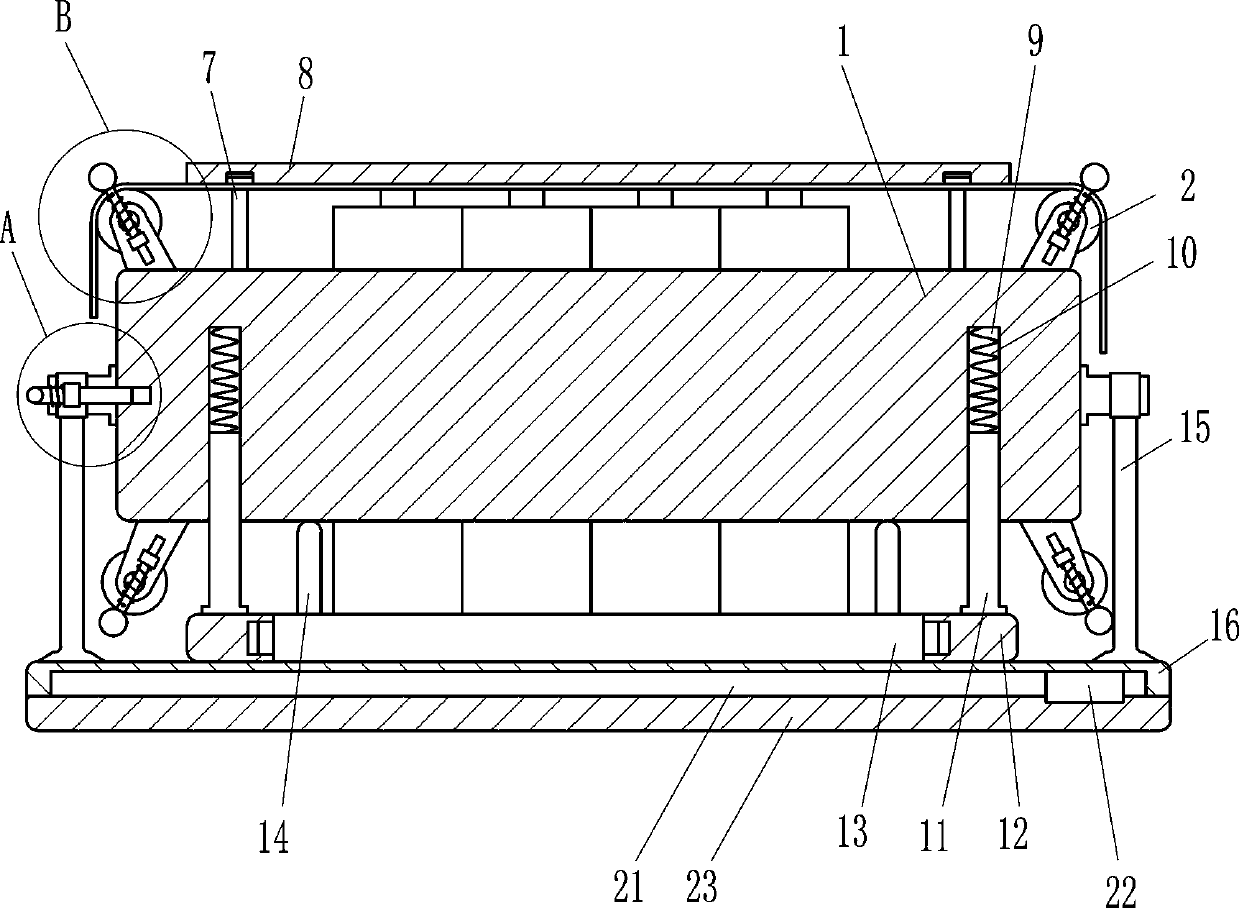

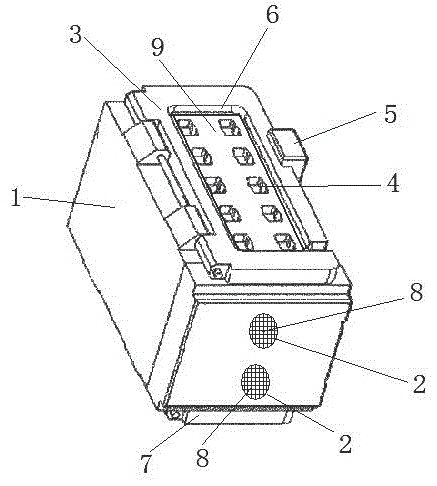

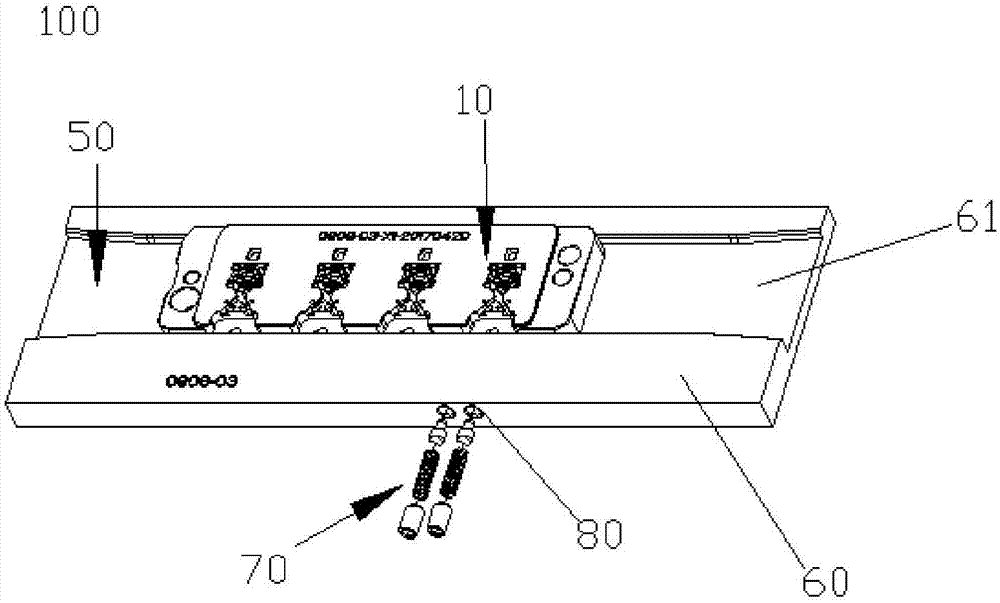

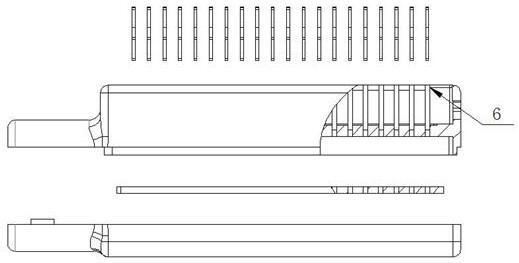

Spot welding jig for lithium battery pack

InactiveCN105127641AConvenient spot weldingSimple structureFinal product manufactureWelding/cutting auxillary devicesEngineeringCopper

The invention discloses a spot welding jig for a lithium battery pack. The spot welding jig comprises a cuboid-shaped jig shell, wherein the lithium battery pack to be subjected to spot welding is placed in the cavity of the jig shell; two ventilation holes used for dissipating heat are formed in each of the two sides of the jig shell up and down; a spot welding cover plate is hinged to one side of the upper surface of the jig shell; a rectangular through hole is formed in the upper surface of the spot welding cover plate; the rectangular through hole is connected with a locating plate in a clamping manner; locating slots used for locating the anodes of lithium battery single bodies in the lithium battery pack are formed in the locating plate at equal intervals; a fixed clamping plate is arranged between the front end of the spot welding cover plate and the jig shell. According to the spot welding jig for the lithium battery pack provided by the invention, lithium battery packs composed of lithium battery single bodies with different numbers can be located and fixed, spot welding for a conductive copper sheet is facilitated, and the spot welding jig is simple in structure, easy to achieve and good in application prospect.

Owner:江苏绿伟锂能有限公司

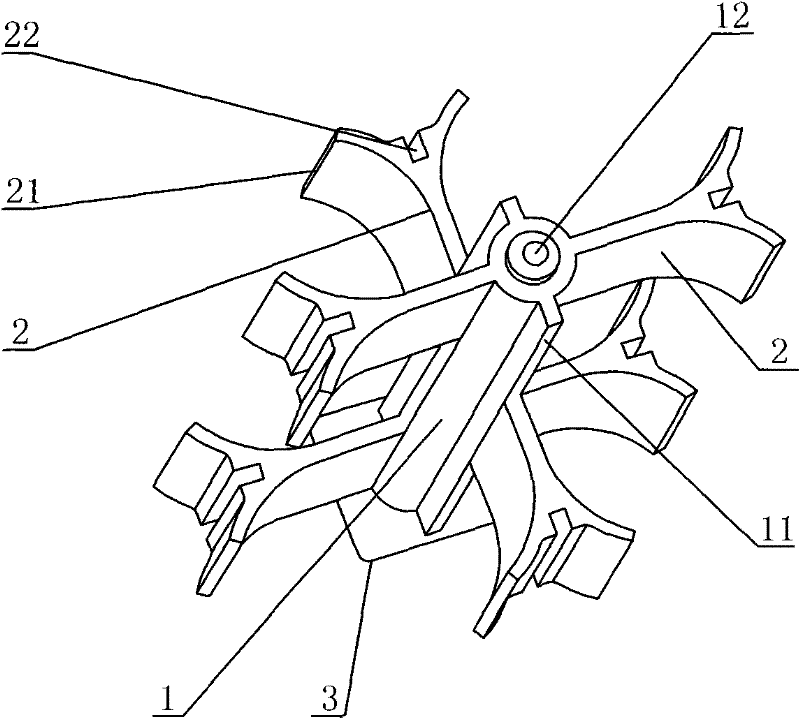

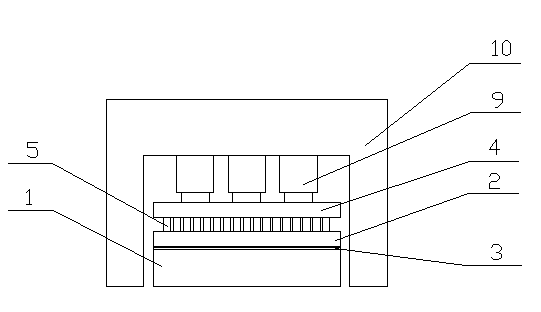

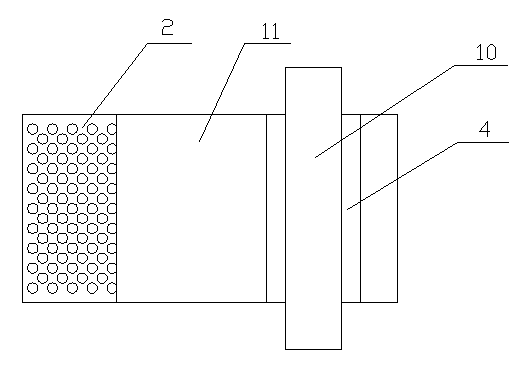

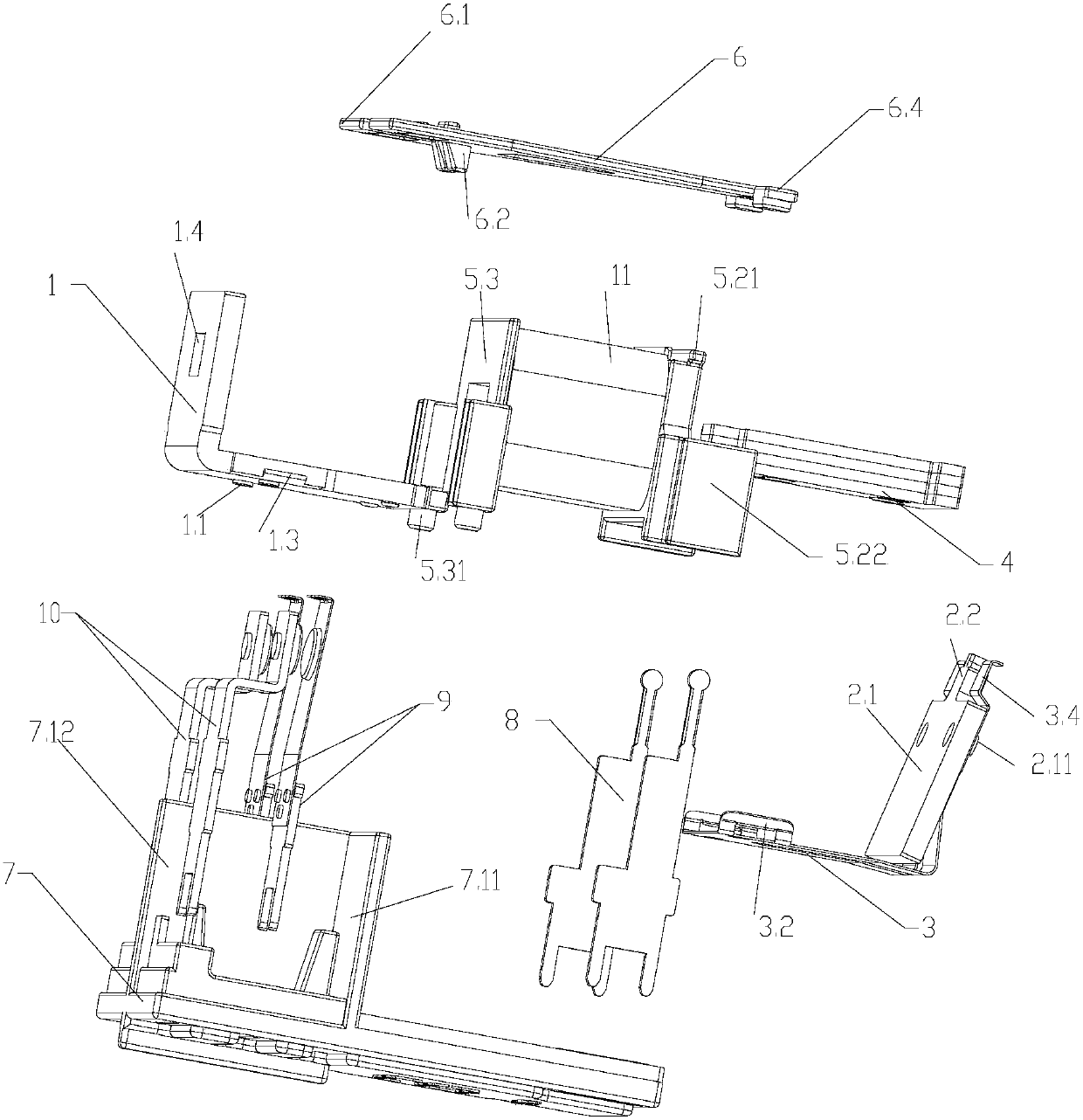

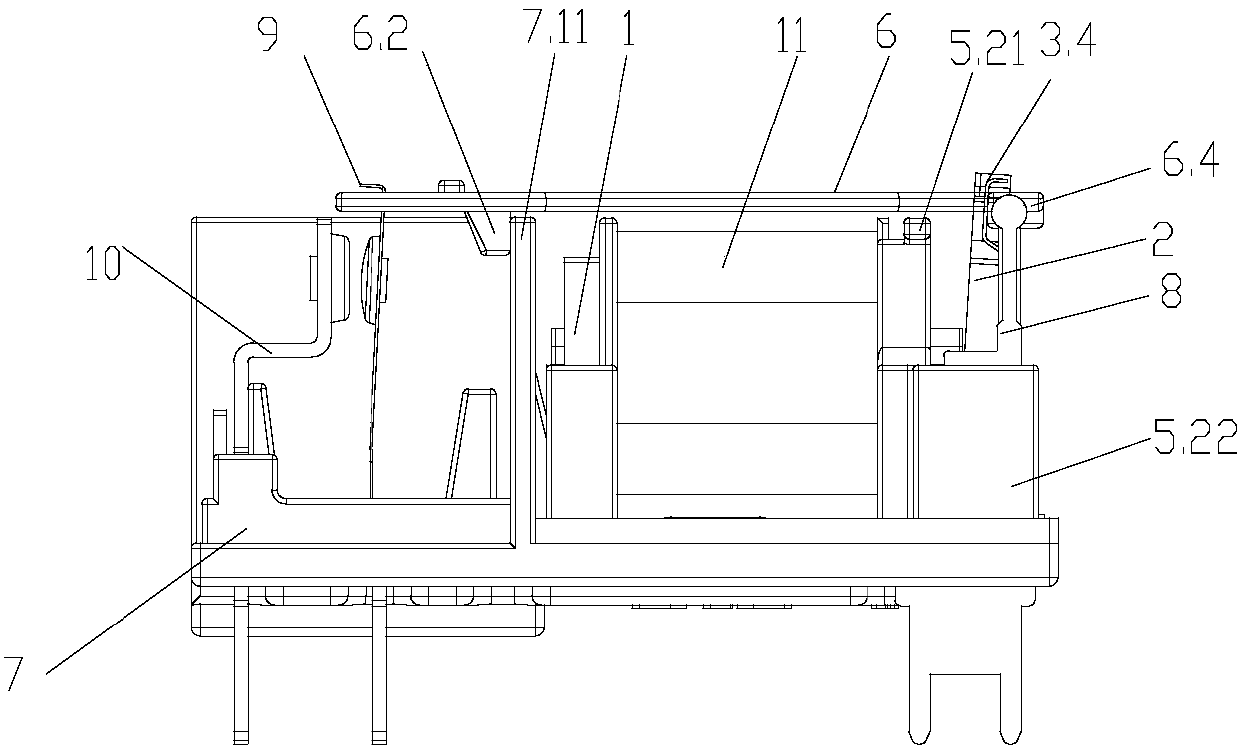

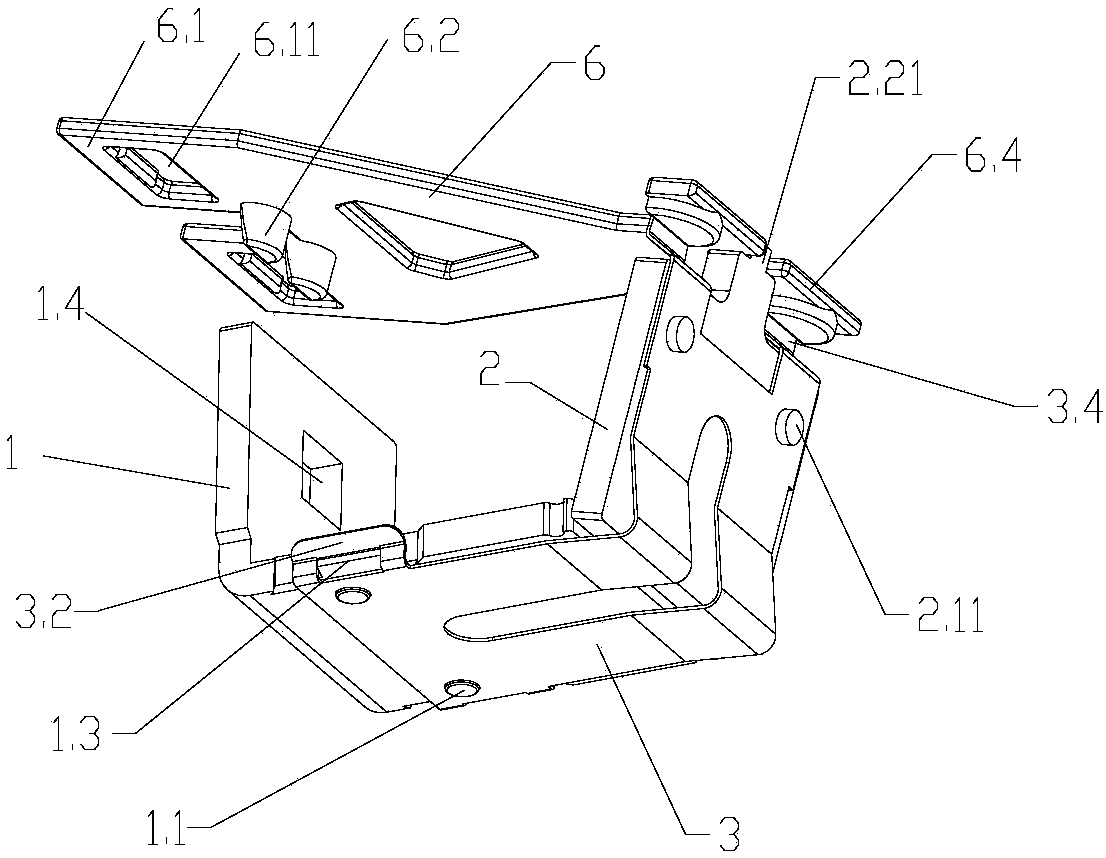

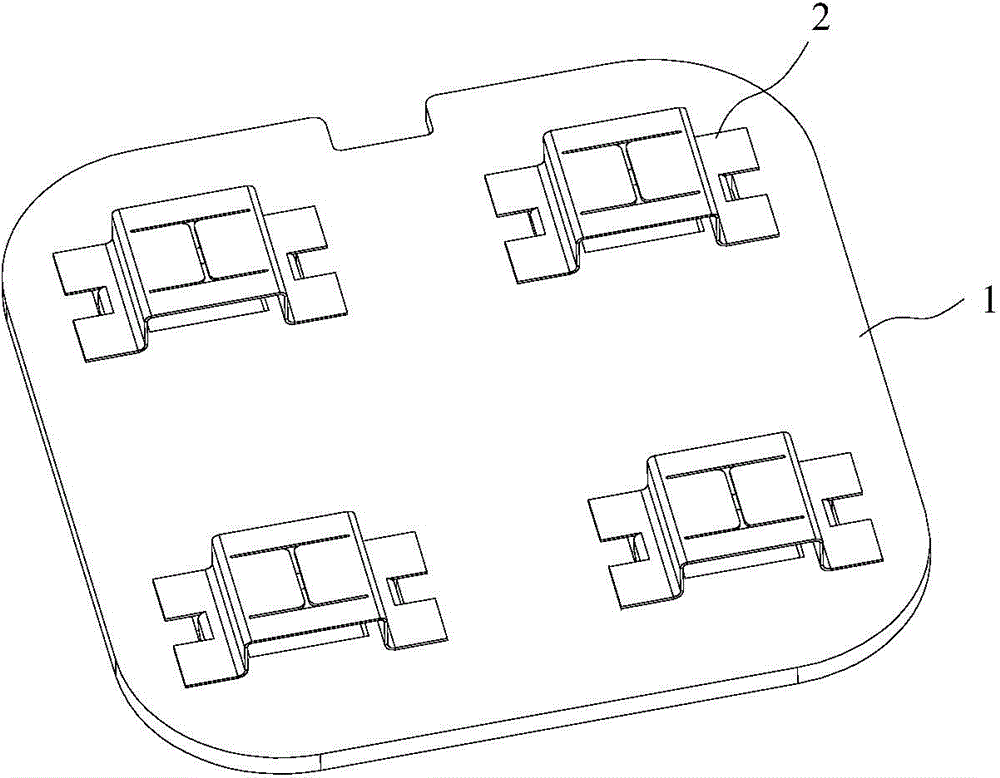

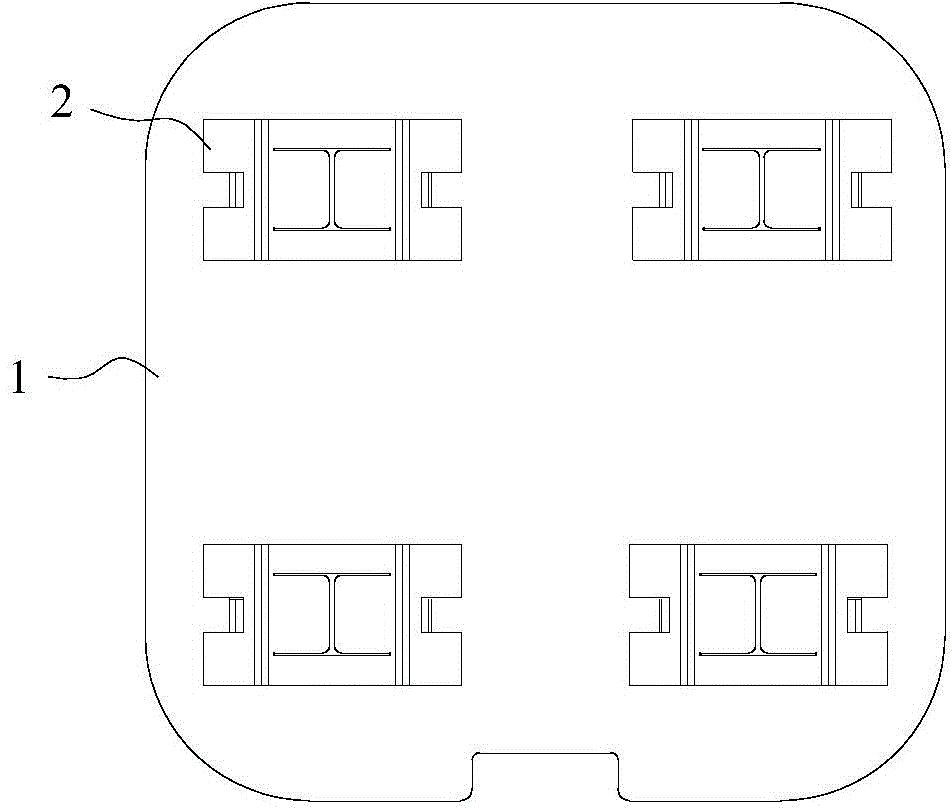

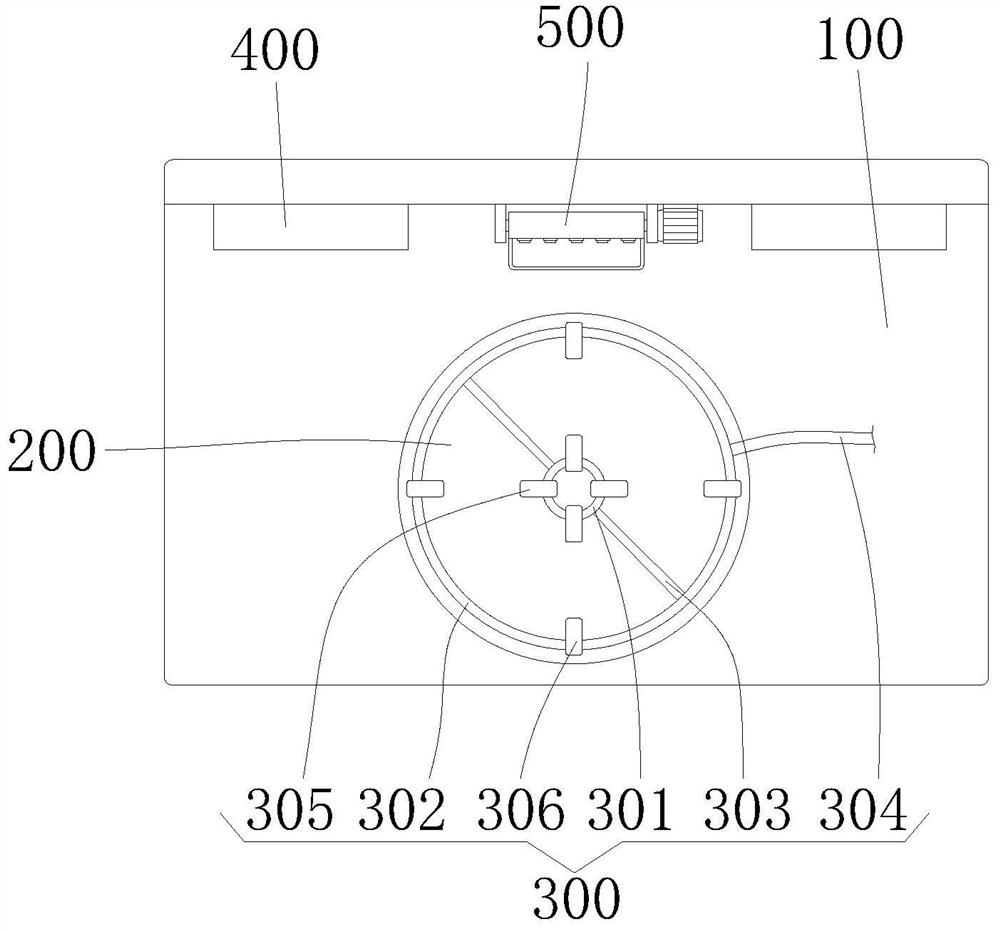

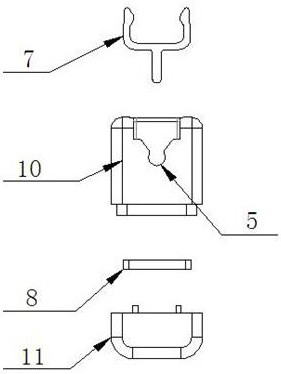

Battery bracket component and multi-section combined public bracket of cylindrical battery cells

ActiveCN102244216AOrderly rowsPrevent shock failureElectric propulsion mountingCell component detailsBattery cellElectrical and Electronics engineering

The invention relates to the technical field of batteries, and particularly discloses a battery bracket component and a multi-section combined public bracket of cylindrical battery cells. The component comprises a central framework; three pairs of side wings and assembly edges are arranged on the upper, middle and lower parts of the central framework respectively; an assembly groove is arranged on each side wing; multiple battery bracket components can be combined through the assembly grooves and assembly edges to form the multi-section combined public bracket of cylindrical battery cells; and the bracket also comprises fixed assembly blocks which are fixedly connected with the battery bracket components through screws. Through the structure disclosed by the invention, the die does not need to be frequently opened according to different numbers of battery cells, thereby saving cost. In the invention, the brackets support one another to realize three-dimensional protection on the battery cells in six directions, thereby effectively preventing impact failure between batteries. By adopting the structure disclosed by the invention, the assembly is convenient, the operation is simple, and the cost of manual assembly is not increased due to the reduction of die expenses.

Owner:SHENZHEN OUSHENG AUTOMATION CO LTD

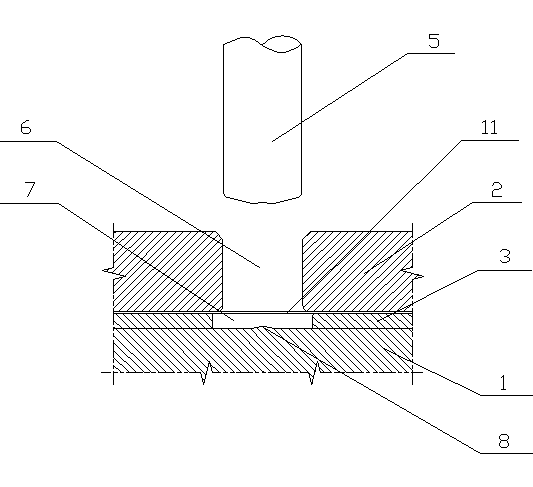

Stamping tool of plate-shell type evaporator plate bundle element

The invention discloses a stamping tool of a plate-shell type evaporator plate bundle element, belonging to the field of punch forming machinery. The stamping tool comprises a bottom platform, an upper die, a lower die, a punch plate bundle, a hydraulic driving device and a portal frame, wherein the hydraulic driving device is fixedly arranged at the lower end of the portal frame, the punch plate bundle is fixedly arranged at the lower end of the hydraulic driving device, the upper die is arranged below the punch plate bundle, and the upper die is provided with a plurality of uniformly distributed upper die through holes; punches of the punch plate bundle are arranged in the upper die through holes, the lower die is arranged on the bottom platform and is provided with a plurality of uniformly distributed lower die through holes, and the lower dies are arranged between the bottom platform and the upper die. The stamping tool of the plate-shell type evaporator plate bundle elementis high in stamping efficiency, reliable in forming and high in finished product rate.

Owner:金沙 +2

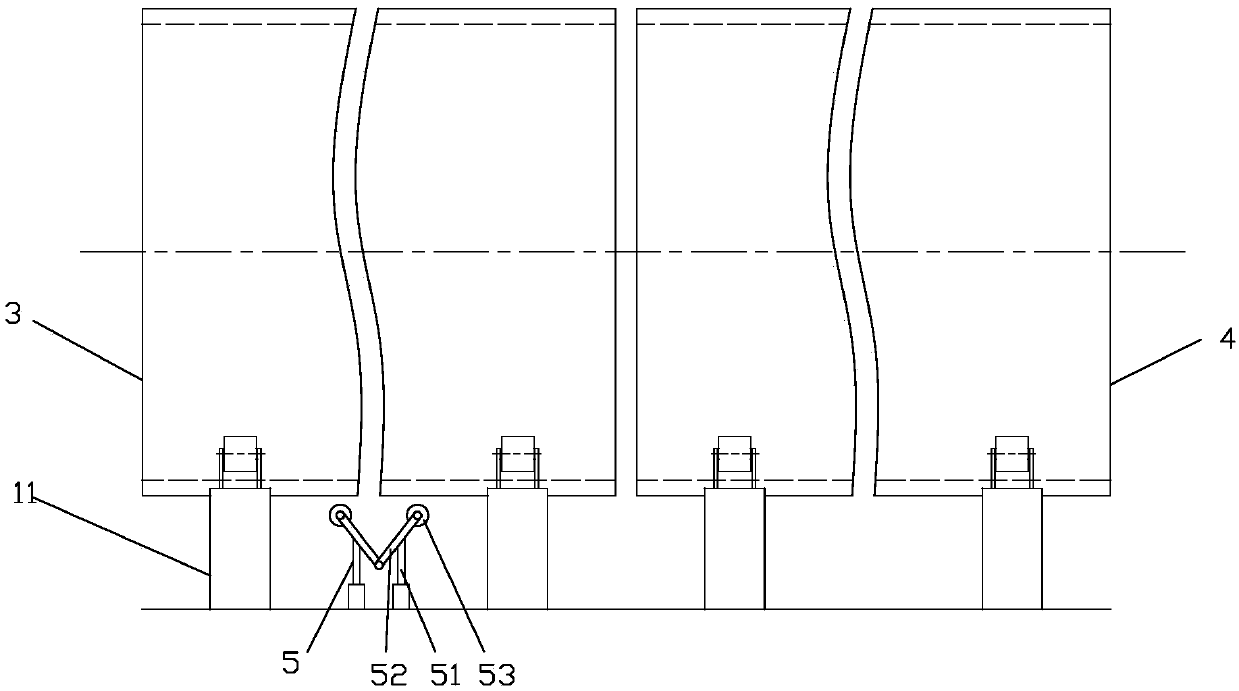

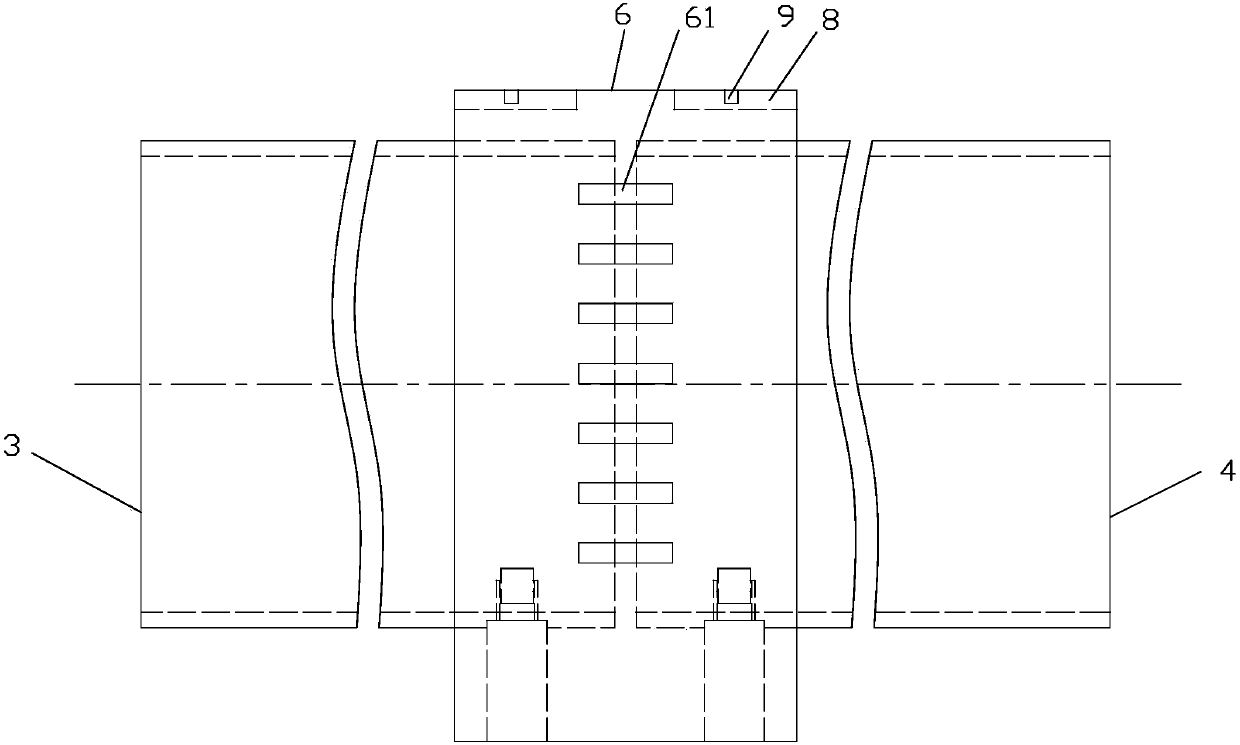

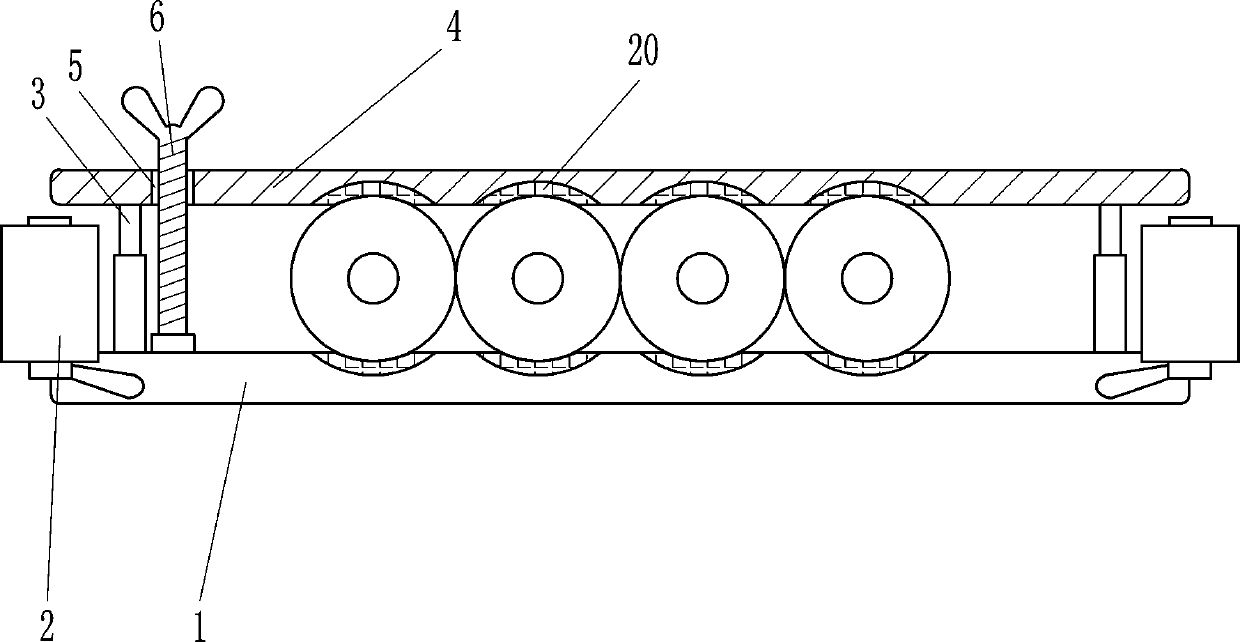

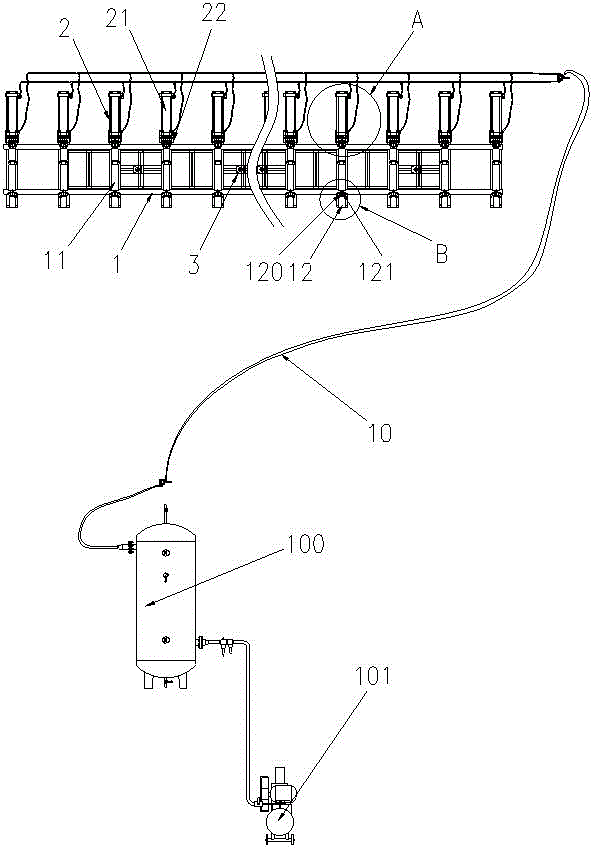

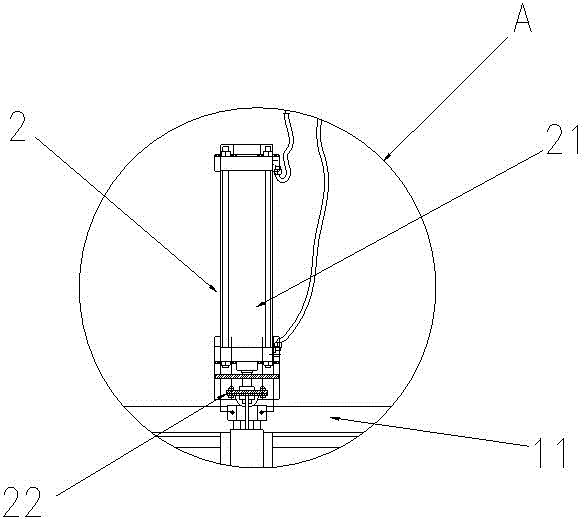

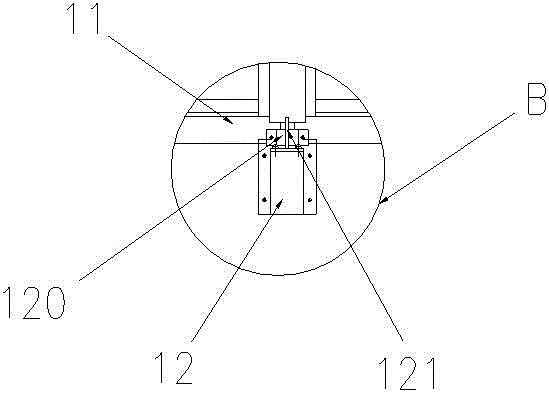

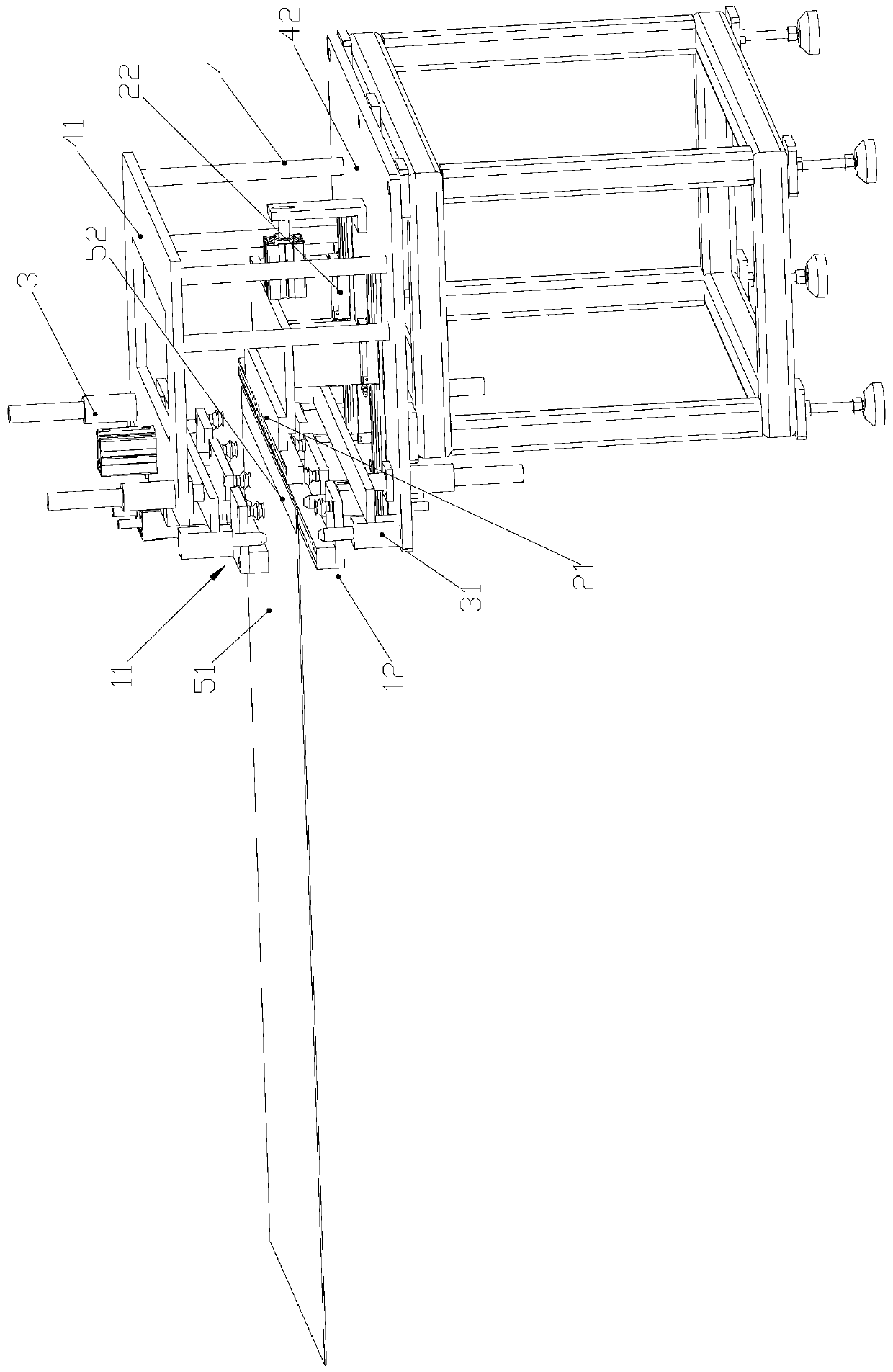

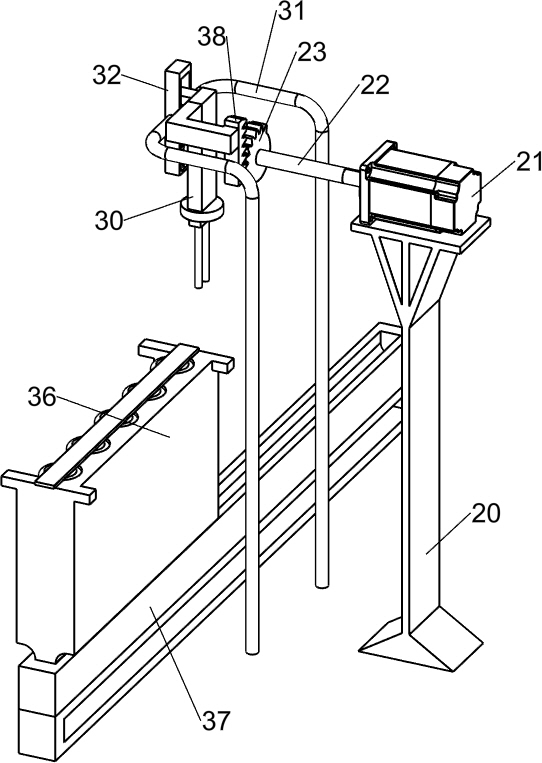

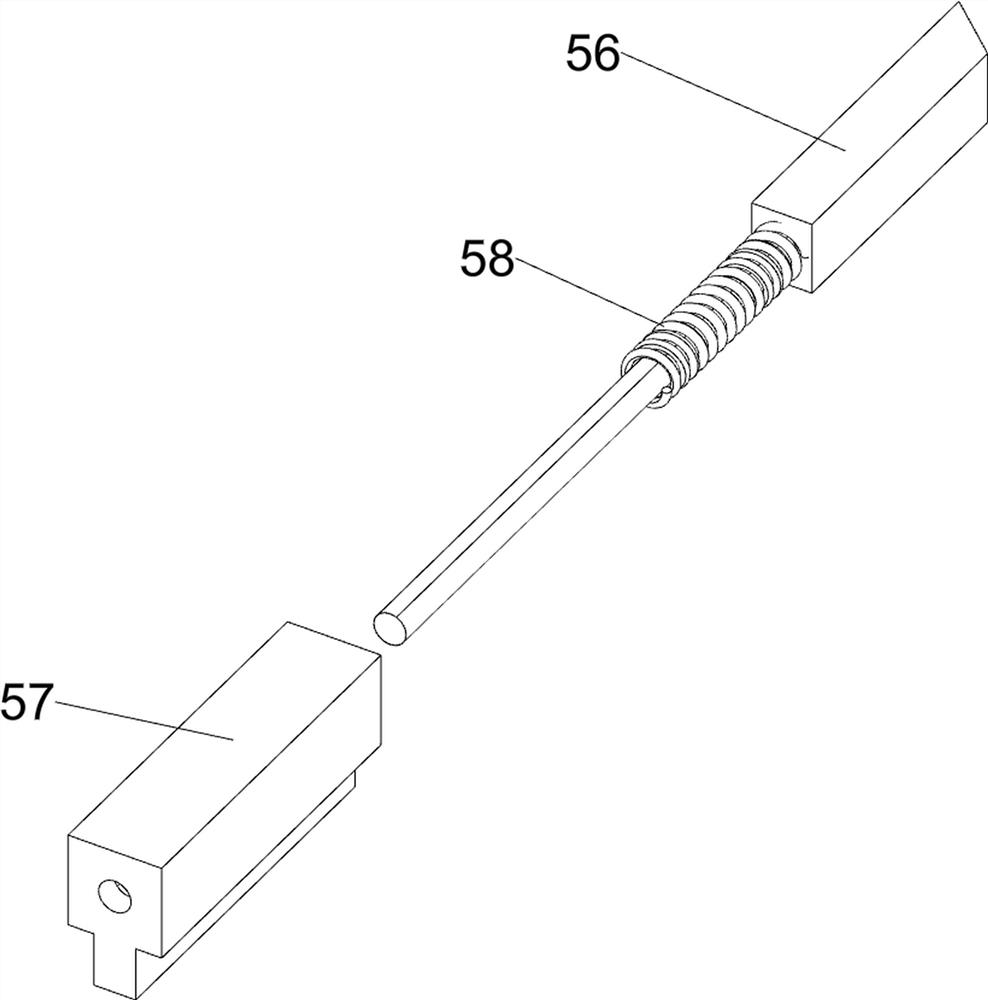

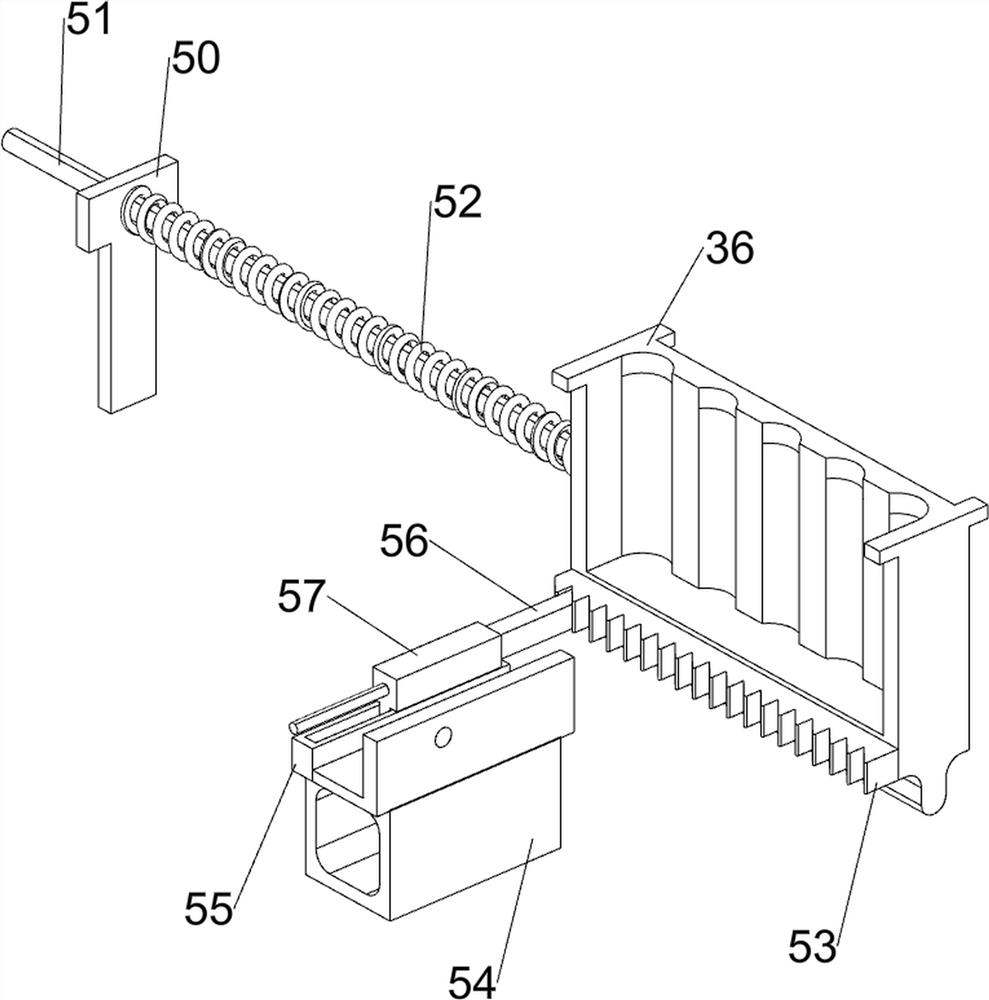

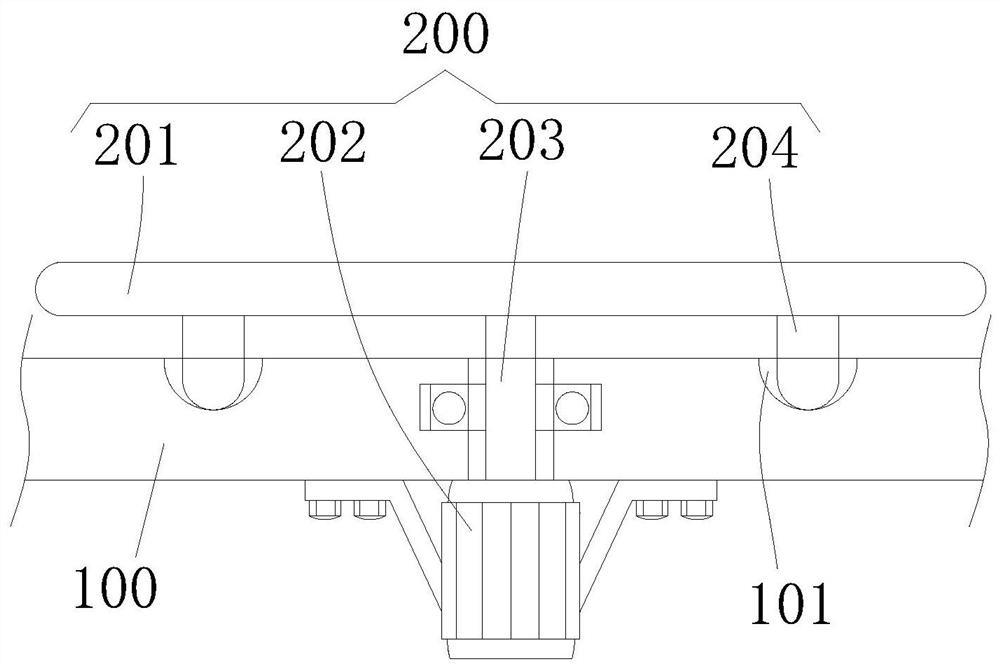

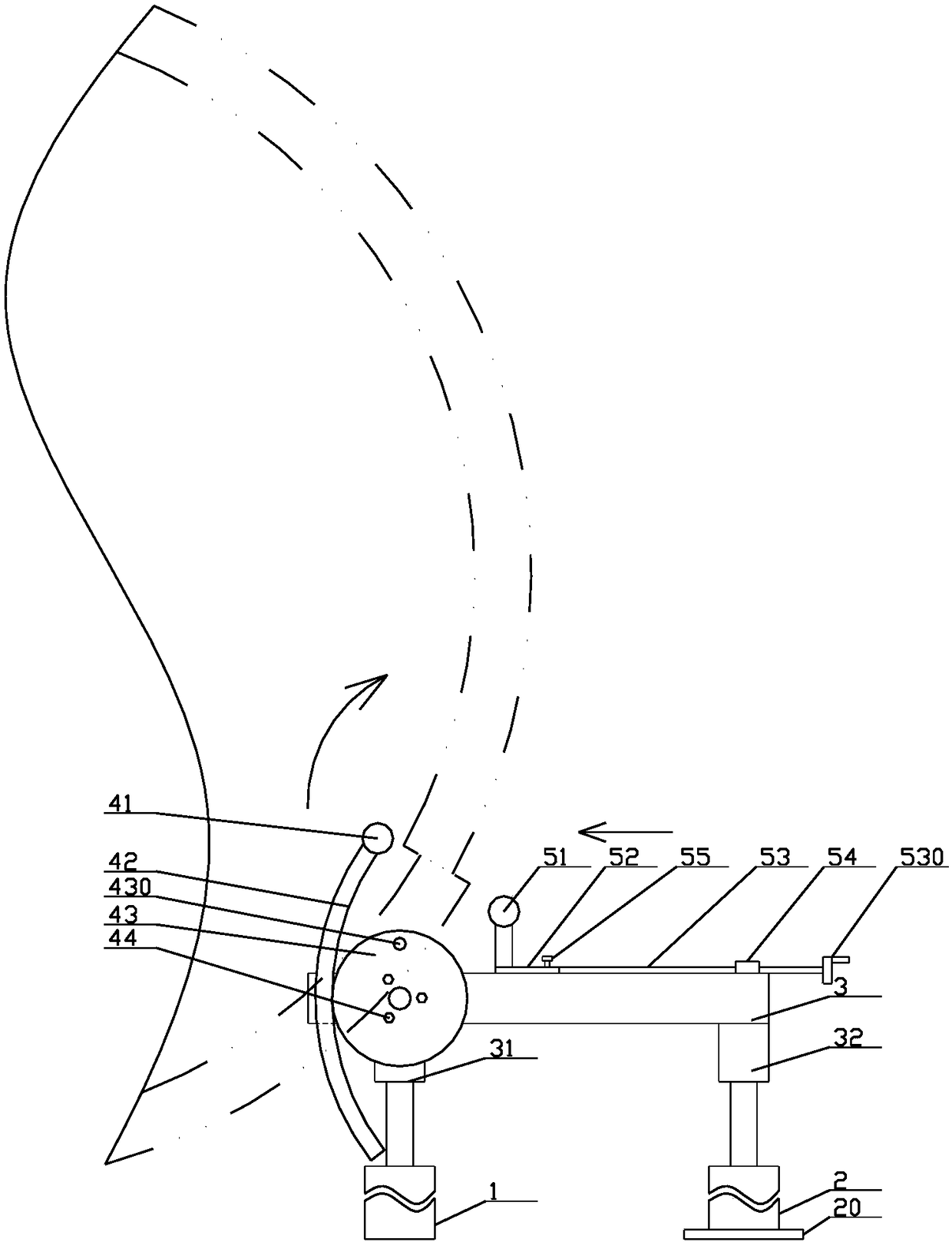

Frame longitudinal beam assembly system

ActiveCN105880879AAdjustable distanceConvenient spot weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a frame longitudinal beam assembly system. The frame longitudinal beam assembly system comprises a frame, multiple sets of air pushing devices and multiple ejecting devices; a conveying roller is mounted on the frame; a fixed stop base is arranged on one side of the frame, and a mounting base of the air pushing devices is mounted on the other side; the ejecting devices are mounted at the bottom of the frame, and are positioned below the conveying roller; the air pushing devices are mounted on the mounting base; each set of air pushing devices includes a cylinder and a pushing mechanism; the pushing mechanisms include pushing bases and guide rod bases; and the pushing bases and the guide rod bases are laminated on cylinder tops, so that the cylinder tops can drive the pushing bases to link. The frame longitudinal beam assembly system uses the air pushing devices for pushing a wing plate on one side to a web plate, and can enable the fixed stop base to assemble a wing plate on the other side with the web plate, so that the adjustment of a distance between the wing plate and the web plate is realized, the primary spot welding is convenient, and the ejecting devices are matched to adjust the height of the web plate to reach the middle of the wing plate.

Owner:GUANGDONG GAODA HEAVY IND MACHINERY IND

Spot welding tool for hose support assembly

InactiveCN112372200APrecise positioningPrevent affecting welding qualityWelding/cutting auxillary devicesAuxillary welding devicesElectric machinerySlide plate

The invention discloses a spot welding tool for a hose support assembly. The spot welding tool comprises two oppositely-arranged supporting seats; a positioning table is fixed to the top ends of the two supporting seats; positioning grooves are formed in the two sides of the top of the positioning table; transverse rods are assembled on the two sides of the inner walls of the positioning grooves;the outer parts of the transverse rods are sleeved with reset springs; one end of each reset spring is fixedly matched with an extrusion plate; upper clamping plates are elastically connected to the sides, close to each other, of the two extrusion plates; extrusion wheels are arranged on the sides, away from each other, of the two extrusion plates in a contact mode; L-shaped plates are assembled on the extrusion wheels; sliding plates are fixed to the two sides of the top of the positioning table; first push rod motors are connected between the positioning table and the L-shaped plates; and electric sliding table sets are assembled at the tops of the two sliding plates. The situation that the welding quality is affected due to the fact that a hose support inclines and slides in the spot welding process is prevented, welding can be smoothly conducted, the spot welding quality of the hose support is improved, operation is easy, the practicability is high, and the spot welding tool is suitable for popularization.

Owner:十堰昌旺工贸有限公司

Machining fixture for turnover bracket

InactiveCN110449808ASimple structureConvenient spot weldingWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention provides a machining fixture for a turnover bracket. The machining fixture for the turnover bracket comprises wiping seats and leaking slots; an installation seat is of a square cavity structure, and an installation plate with installation holes is arranged on the bottom surface of the installation seat; a cocked pressing plate is arranged on the top surface of the installation seat,and the pressing plate is parallel to the top surface of the installation seat; and a middle notch of a kidney circular notch structure is formed in the middle position of the pressing plate, two welded nuts are welded to the middle notch, two lock-pressing bolts are arranged downwards in a screw-thread fit mode through the two welded nuts, a welded notch area corresponding to stand plate clamping slots is arranged, spot welding can be conveniently carried out when stand plates constituting the turnover bracket are in butt joint with a bottom constituting the turnover bracket, the wiping seats are installed on notches of the welded notch structure and clamping slot structure areas, the wiping seats are used for wiping off oxide skin welding slag beat by welding spots when the turnover bracket after spot welding is pulled out outwards, the oxide skin welding slag leaks outwards through the leaking slots, and a functional structure is improved.

Owner:十堰市弘康汽配科技有限公司

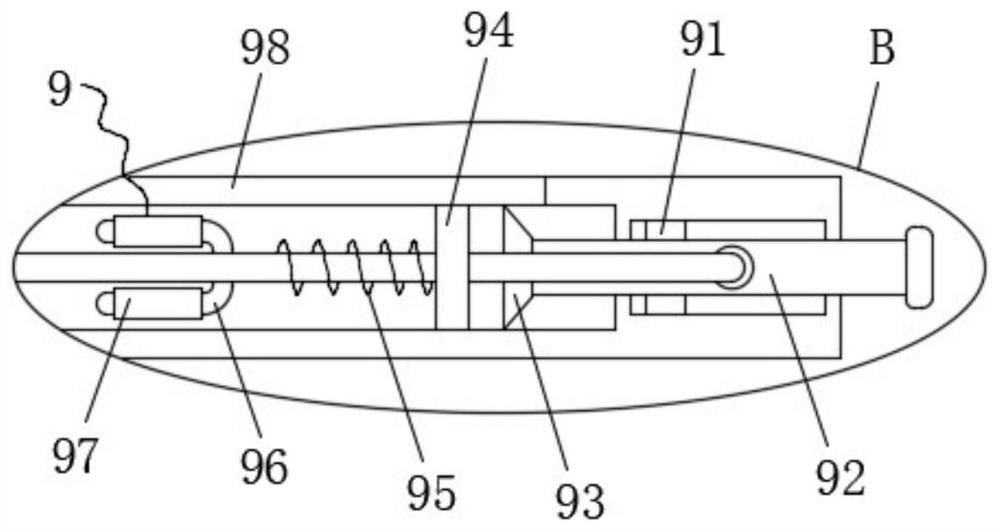

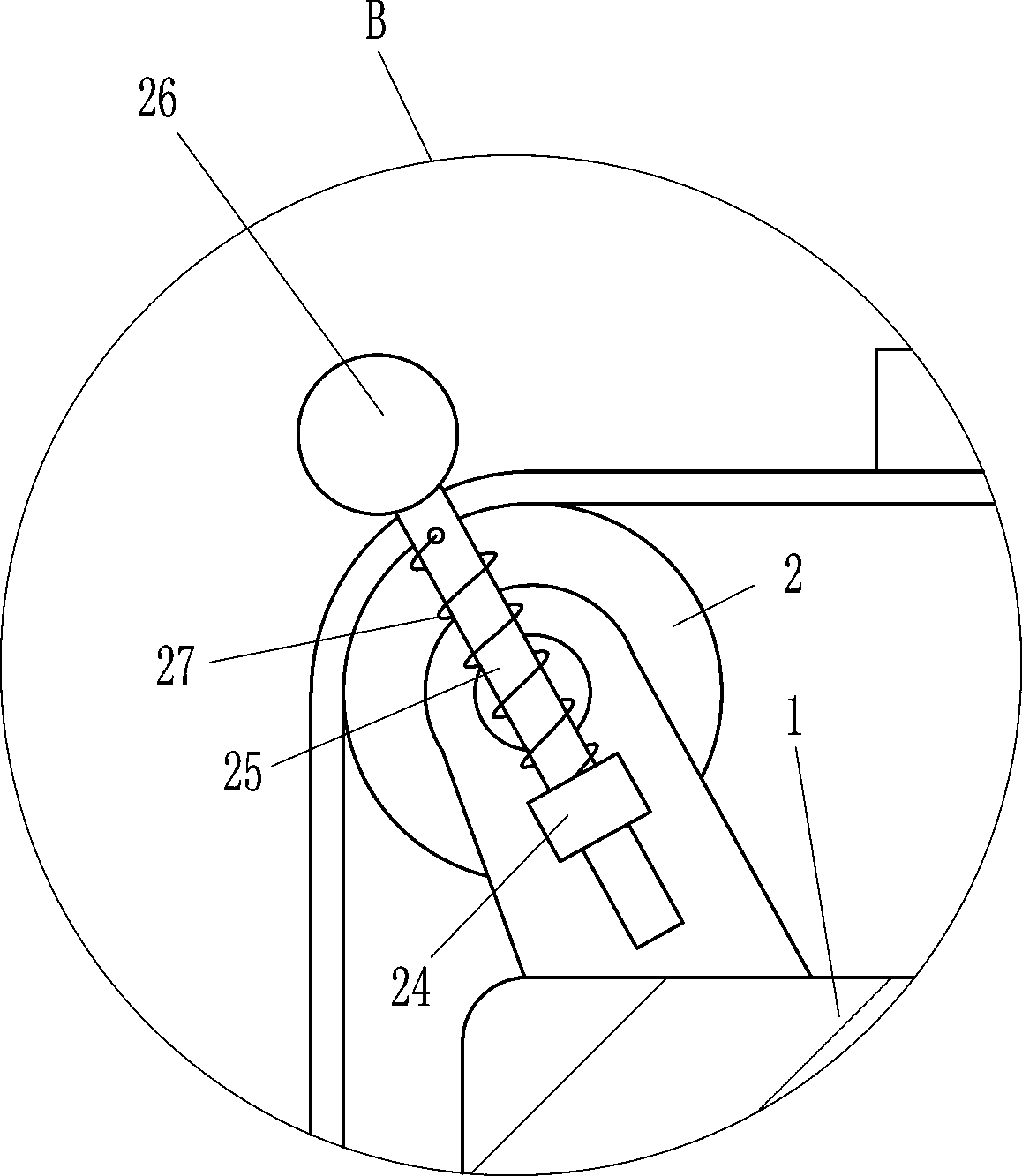

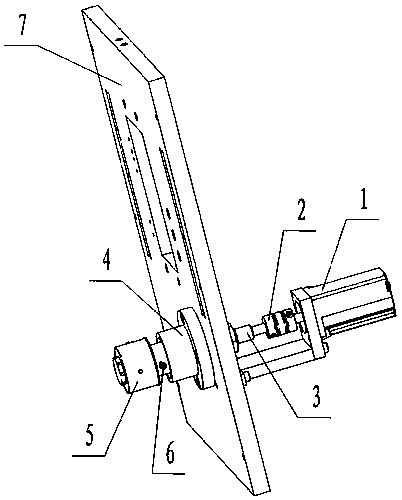

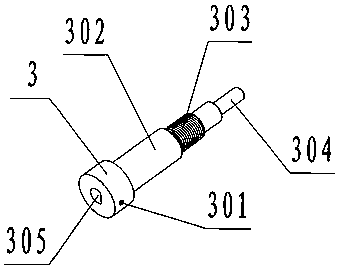

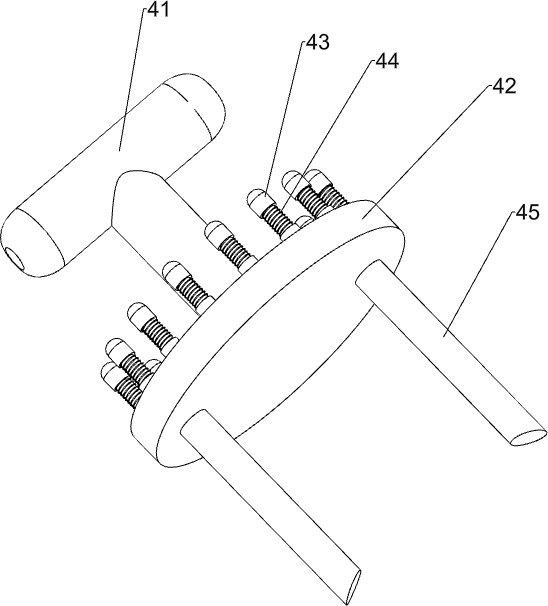

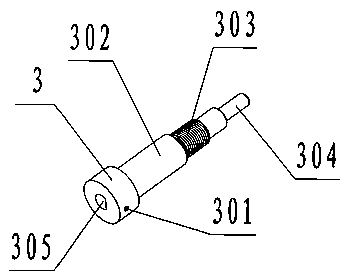

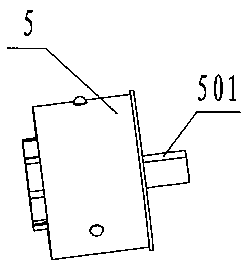

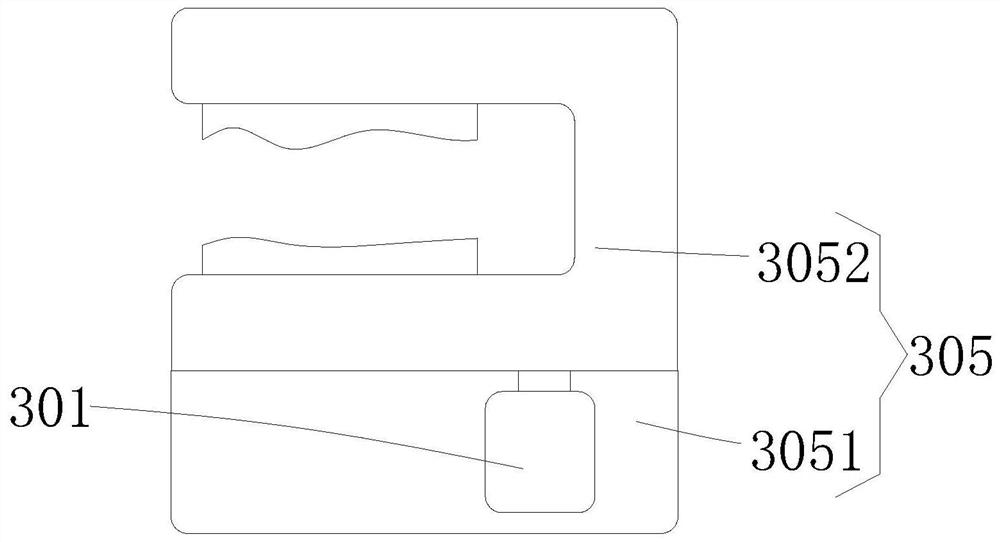

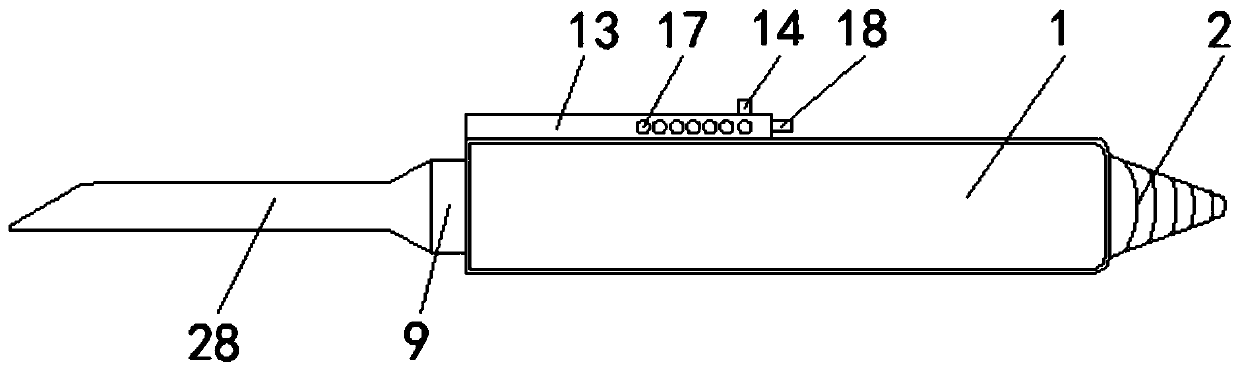

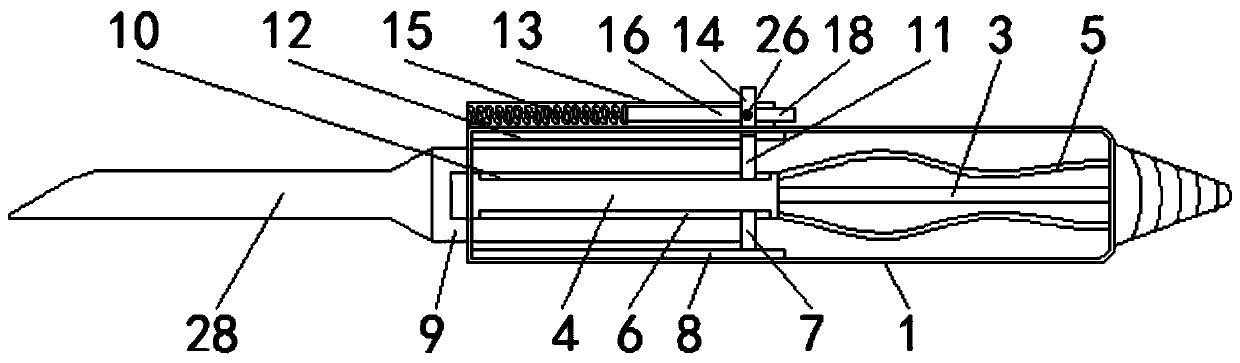

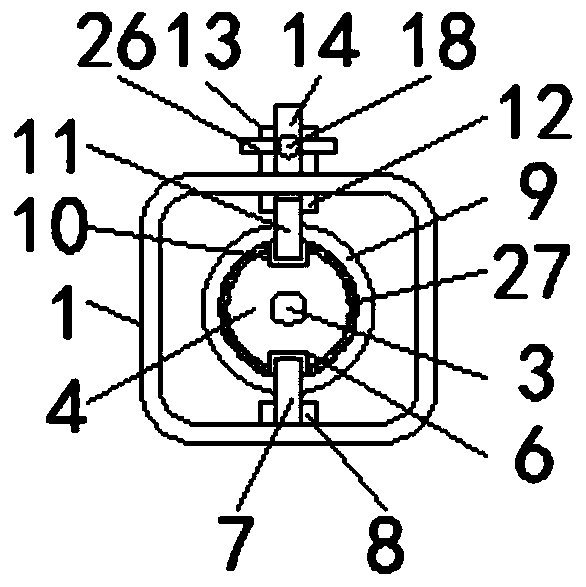

Material incoming tensioning mechanism of circular electric plug spot welding device

ActiveCN108381071AImprove work efficiencyConvenient spot weldingWelding/cutting auxillary devicesAuxillary welding devicesElectricityEngineering

The invention discloses a material incoming tensioning mechanism of a circular electric plug spot welding device. The material incoming tensioning mechanism comprises a tensioning head for tensioningmaterials, and the tensioning head is connected to one end of a conductive mandrel driven to rotate by a stepping motor and rotates synchronously with the conductive mandrel. The tensioning head comprises a cylindrical outer shell body and a fastening core which are sleeved with each other, and holes are uniformly formed in the outer side surface of the outer shell body in the circumferential direction. After the outer shell body and the fastening core are connected in a sleeved mode, cavities for receiving butting columns are formed in the tensioning head. One ends of the butting columns anda tensioning force adjusting mechanism on the tensioning head are installed in a matched mode, and the tensioning force adjusting mechanism applies different force to the butting columns, so that butting column heads on the end portions of the butting columns protrude from the holes on the side surface of an outer shell by different lengths to control the degree of tension of the materials on thetensioning head. The material incoming tensioning mechanism of the circular electric plug spot welding device tension the incoming materials during spot welding and can automatically distribute the rotary indexing within 360 degrees in the circumference to facilitate the spot welding, so that the working efficiency of the circular electric plug spot welding device is greatly improved.

Owner:HENAN UNIV OF SCI & TECH

Long-service small-sized electromagnetic relay

PendingCN108039306AAvoid failureAchieve contactElectromagnetic relay detailsEngineeringFailure causes

The invention discloses a long-service small-sized electromagnetic relay. The long-service small-sized electromagnetic relay comprises a yoke iron, an armature, an elastic piece, an iron core assembly, a coil frame, a push rod and a base, wherein the iron core in a nesting structure penetrates through an iron core hole of the coil frame and is riveted to a vertical section of the yoke iron, the yoke iron and the armature are steadily combined by virtue of a ''reverse L-shaped'' elastic piece, the coil is electrified to work, the armature is actuated, an armature clamp block and an elastic piece baffle block push the tail of the push rod to drive a movable spring to work, and then a movable contact is in contact with static contact; when the yoke iron and the elastic piece are reset, a limiting rod of the push rod props against an insulation wall of the base, so that the situation that the relay is disabled due to a too-large counter force of the elastic piece is avoided; the coil frameis precisely mounted in the base through a positioning column, and a varnished wire between the coil and a terminal pin is always located on the top surface of a right base plate between two wire clamping bolts, so that the steady wiring is realized. The long-service small-sized electromagnetic relay is compact in structure, stable in performance and good in insulativity, the working failure caused due to over-large actuation voltage can be effectively avoided, the position is precise, and the automatic assembling is easily realized.

Owner:YUEQING MEISHUO ELECTRIC

New energy automobile part shell welding device

InactiveCN112355640AConvenient spot weldingEasy spot welding deviceOther manufacturing equipments/toolsMaintainance and safety accessoriesPhysicsMotor vehicle part

The invention relates to the technical field of welding, in particular to a new energy automobile part shell welding device which comprises a workbench, two sets of fixed rotating devices, a spot welding device, a polishing device and a cleaning device. The workbench is arranged on the horizontal plane; the two sets of fixed rotating devices are symmetrically arranged on the surface of the workbench; the spot welding device is arranged on the workbench; the polishing device is arranged on the workbench and located on the side right opposite to the spot welding device; the cleaning device is arranged on the workbench; the cleaning end of the cleaning device is located over the two sets of fixed rotating devices; a new energy automobile part shell is placed on the two sets of fixed rotatingdevices so as to be fixed; the spot welding device is used for welding the new energy automobile part machine shell; the polishing device polishes a whole pipeline; and the cleaning device cleans andcools the new energy automobile part machine shell subjected to polishing and sport welding and the polishing device, so that the cleanliness of the device and the new energy automobile part machine shell is improved.

Owner:李登进

PCB welding device

PendingCN113977138ANo manpower requiredImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses a PCB (printed circuit board) welding device, which relates to the field of circuit board welding and comprises a worktable, a spot welding device is arranged on the surface of the worktable and movably connected with the worktable, a movable clamp is arranged at the front end of the spot welding device and slidably connected with the worktable, a fixed clamp is arranged at one side of the movable clamp, the fixed clamp is fixed to the surface of the worktable, the fixed clamp and the movable clamp are the same in structure, a feeding table is fixedly connected to the side wall of the worktable, a storage groove is formed in the rear end of the feeding table, and a lifting device is arranged in the storage groove. According to the invention, the feeding table is arranged, PCBs are stacked in the storage groove, the PCBs are pushed by a pushing device, the PCBs at the top are made to be tightly attached to a fixed baffle, then the PCBs at the uppermost end are pushed into the clamp through the pushing device to be clamped, and after spot welding, and the PCBs are attracted to a conveying belt through a traction plate and conveyed through the conveying belt; and operation is convenient and rapid, and manpower is not needed.

Owner:广德王氏智能电路科技有限公司

Surface-mounted protecting plate and battery pack with same

ActiveCN104681759AThe overall structure is simple and reliableSimple structureCell component detailsBrickElectrical battery

The invention discloses a surface-mounted protecting plate and a battery pack with the protecting plate. The surface-mounted protecting plate comprises a protecting plate base material and a plurality of patch nickel straps arranged at the upper side of the protecting plate base material, wherein an opening is formed in one side, opposite to a welding part, of the protecting plate base material, and a plurality of nickel bricks are arranged at the lower side, near to the edge, of the protecting plate base material. Cylindrical batteries are connected with the patch nickel straps of the surface-mounted protecting plate of the battery pack in a spot welding manner, wherein electrodes on the top end of each cylindrical battery are led to the protecting plate by being in connection with the nickel straps and are connected with the nickel bricks arranged at the bottom side of the protecting plate in the spot welding manner, and internal circuits which are connected with the patch nickel straps and the nickel bricks are arranged on the protecting plate base material so as to connect the cylindrical batteries in sequence and in series. The surface-mounted protecting plate has the advantages that a battery production technology is simplified, the multi-station spot welding is combined, the spot welding frequency is reduced, the spot welding defect rate is greatly reduced, the production and operation are simple, the structure stability is relatively high, the battery production efficiency is improved to a large extent, simultaneously the automatic production can be realized, and the high-efficiency, high-quality and low-cost product delivery is ensured.

Owner:SHENZHEN AMPOWER NEW ENERGY CO LTD +3

Full-automatic inner container woven bag inner folding edge winding pre-welding device

PendingCN110450457AConvenient spot weldingReduce the failure rateBag making operationsPaper-makingEngineeringSpot welding

The invention discloses a full-automatic inner container woven bag inner folding edge winding pre-welding device. An upper suction cover assembly comprises an upper guide rod cylinder, an upper suction plate and an upper suction cup, a lower suction cover assembly comprises a lower guide rod cylinder, a lower suction plate and a lower suction cup, an air suction positioning assembly comprises an air suction plate, a linear guide slider, a double-position cylinder and a mounting supporting frame, a ultrasonic spot welding assembly comprises two groups of upper and lower ultrasonic spot weldingmachines, an air cylinder, a linear bearing and a guide rod, a packaging woven bag comprises a woven bag outer bag and a woven bag inner container, the upper suction assembly and the lower suction assembly respectively perform opposite movement and back movement, the air suction plate moves towards the woven bag inner container along the linear guide rail slide block under the driving of the double-position air cylinder, and the upper ultrasonic spot welding machine and the lower ultrasonic spot welding machine carry out opposite movement and finish spot welding on packaging woven bags. According to the full-automatic inner container woven bag inner folding edge winding pre-welding device, the reject ratio is greatly reduced, the automation degree is high, the positioning is accurate, andthe rate of finished products and the welding efficiency are greatly improved.

Owner:CHANGZHOU JINPU AUTOMATION EQUIP CO LTD

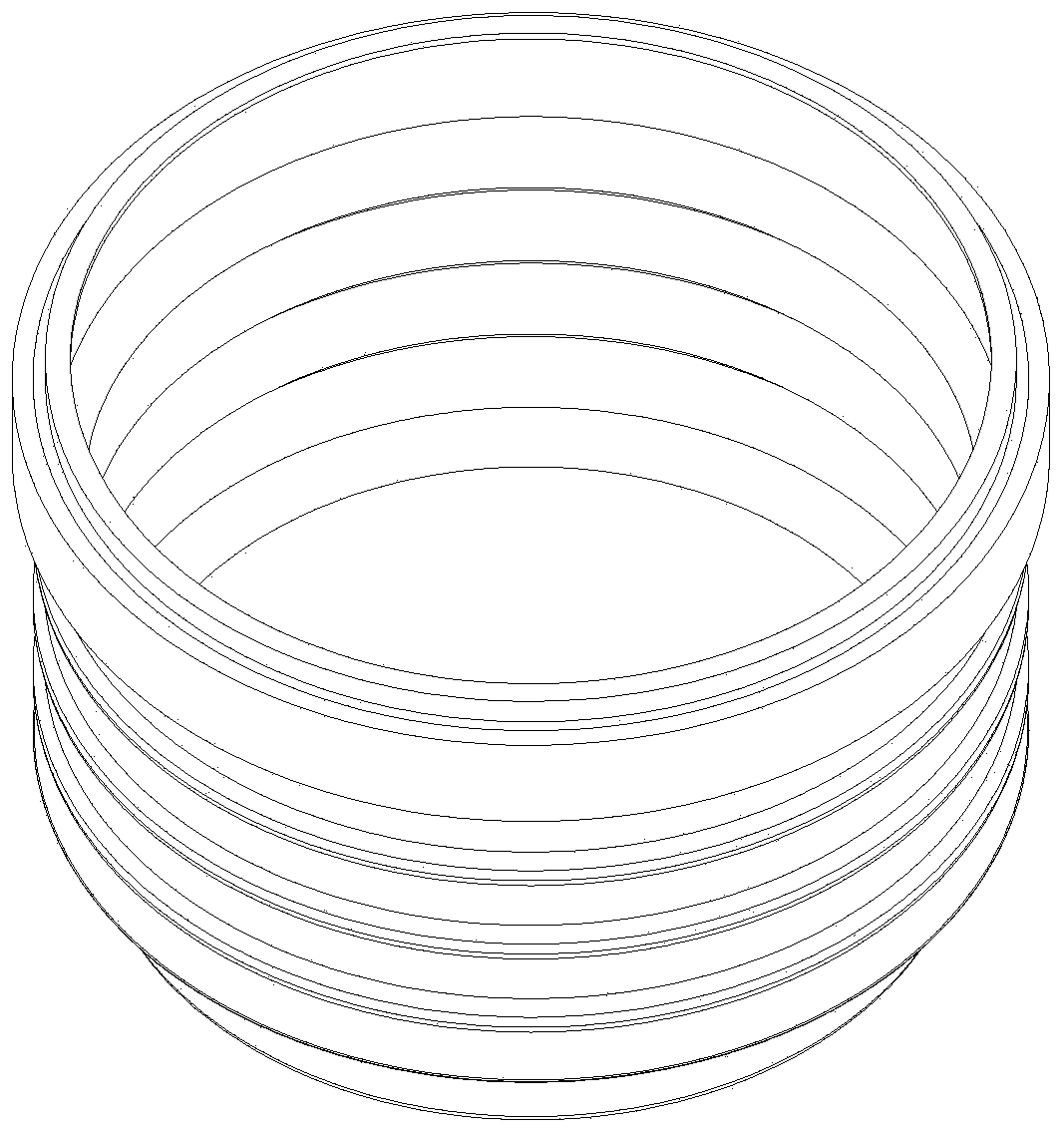

Automatic winding spot welding machine

ActiveCN112809150AHigh speedCreativeFinal product manufactureResistance welding apparatusWinding machineCircular disc

The invention relates to the technical field of spot welding machines, and discloses an automatic winding spot welding machine. The automatic winding spot welding machine comprises a box body, a workbench is fixedly connected to the upper surface of the box body, and an automatic feeding mechanism, an automatic winding mechanism, a wire cutting mechanism, a wire arranging mechanism, a wire cutting mechanism and a spot welding mechanism are arranged on the upper surface of the workbench; the automatic feeding mechanism comprises a first mounting plate, a vibrator, a vibration disc, a straight vibration strip, a vertical plate, a first servo motor, a vacuum pump, a suction cup and a collecting box; and the first mounting plate is fixed to the upper surface of the workbench through bolts, the vibrator is fixedly connected to the first mounting plate, the vibration disc is fixedly connected to one side of the vibrator, and one end of the straight vibration strip is fixedly connected to the vibration disc. Compared with manual discharging, the automatic winding spot welding machine has the advantages that the speed is higher and more accurate, the later winding efficiency can be improved while the feeding efficiency is improved, the problems of unevenness and compactness of manual winding displacement and low manual winding efficiency are solved, and the winding efficiency can be improved to a great extent.

Owner:佛山市宇特自动化科技有限公司

Spot welding equipment for lithium battery gasket

ActiveCN112589246AAchieve driveEasy to fixFinal product manufactureElectrolyte accumulators manufactureGear wheelEngineering

The invention relates to spot welding equipment, in particular to spot welding equipment for a lithium battery gasket. According to the spot welding equipment for the lithium battery gasket, a lithiumbattery can be effectively clamped, the defective rate of spot welding is reduced, and the practicability of the equipment is improved. According to the technical scheme, the spot welding equipment for the lithium battery gasket is characterized by comprising a driving mechanism and a spot welding mechanism, wherein the driving mechanism is connected to one side of the top of a base; and the spotwelding mechanism is connected to the side, close to the driving mechanism, of the top of the base. According to the equipment, through cooperation of a servo motor, a first rotating shaft and a first teeth-uncompleted gear, the purpose of providing driving force for the equipment is achieved.

Owner:湖北林锂新能源有限公司

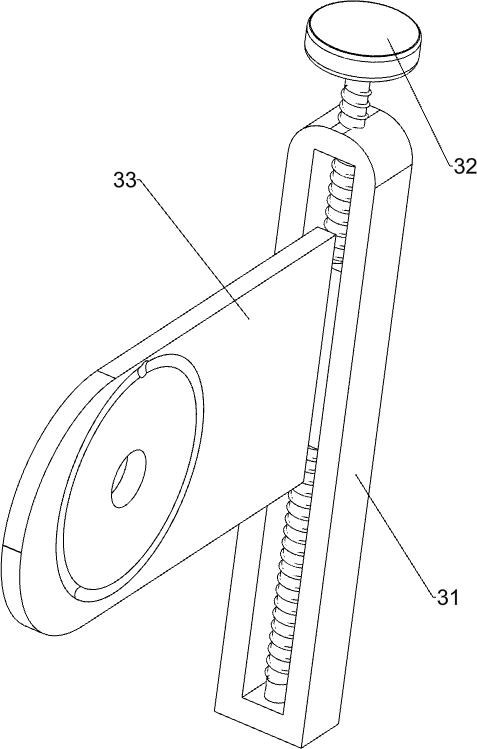

Workbench for iron ring spot welding

ActiveCN111843332AConvenient spot weldingPrevent movementWelding/cutting auxillary devicesAuxillary welding devicesCircular discProtecting eye

The invention relates to a workbench, in particular to a workbench for iron ring spot welding. According to the technical aim, the workbench for iron ring spot welding can protect eyes of workers. Inorder to achieve the technical aim, the workbench for iron ring spot welding comprises a rack connected with a mounting plate, a height adjusting device arranged on the top of the mounting plate, an angle adjusting device installed on the height adjusting device, and a positioning disc connected to the inner top of the mounting plate. The height adjusting device can adjust the height of goggles, and the angle adjusting device can adjust the angle of the goggles, so that workers can conveniently perform spot welding on an iron ring through the goggles, the goggles can protect the eyes of the workers, and the workers do not need to wear glasses when performing spot welding on the iron ring.

Owner:陈泉有

Incoming material tensioning mechanism of a circular electric plug spot welding device

ActiveCN108381071BImprove work efficiencyConvenient spot weldingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineClassical mechanics

An incoming material tensioning mechanism of a circular electric plug spot welding device, including a tensioning head for tensioning materials, the tensioning head is connected to one end of a conductive mandrel driven by a stepping motor, and moves along with the conductive mandrel Rotating synchronously, the tensioning head includes a cylindrical outer casing and a fastening core that are nested in each other. Holes are evenly distributed on the side of the outer casing. After the outer casing and the fastening core are sleeved and connected, a The cavity for holding the top tension column, one end of the top tension column and the tension adjustment mechanism on the tension head are installed together, and the tension adjustment mechanism applies different forces to the top tension column, so that the end of the top tension column The top tensioning studs protrude different lengths from the holes on the side of the outer casing to control the tension of the material on the tensioning head. The present invention can tension the incoming material during spot welding and can automatically evenly distribute and rotate the index within 360° of the circumference to facilitate spot welding, and greatly improves the working efficiency of the spot welding device of the circular electric plug.

Owner:HENAN UNIV OF SCI & TECH

Spot welding jig and device with automatic positioning function

ActiveCN107225355APlay the role of automatic positioningLimit movement directionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention provides a spot welding jig with an automatic positioning function. The spot welding jig comprises a voice soil placement seat and a welding base, wherein the welding base comprises a body and at least one elastic assembly, a sliding groove is formed in the surface of the body, and a first through hole of the at least one elastic assembly is formed in the side wall of the sliding groove; the voice coil placement seat is glidingly arranged in the sliding groove and equipped with at least one group of clamp slots used for accommodating voice coils and voice coil supports; each clamp slot is correspondingly provided with an arc-shaped groove, the arc-shaped grooves are in clamping matching with clamping pieces, and arc-shaped transition is formed between the arc-shaped grooves and a second surface, so that the clamping pieces can enter the arc-shaped grooves and can be discharged from the arc-shaped grooves in a sliding manner. According to the spot welding jig with the automatic positioning function, the clamp slots can be positioned through the at least one elastic assembly and the arc-shaped grooves, so that the position of a spot welding point is determined automatically; the at least one elastic assembly can be elastically clamped with the arc-shaped grooves in the sliding direction sequentially by moving the voice coil placement seat, and the great convenience is brought to the spot welding process of the voice coils. The invention further provides a spot welding device with the automatic positioning function.

Owner:重庆市冠音泰科技有限公司

Auxiliary equipment for spot welding of electronic elements

InactiveCN113059309APrevent crushingImprove work efficiencyLighting elementsWelding/cutting auxillary devicesSpot weldingElectronic component

The invention discloses auxiliary equipment for spot welding of electronic elements, and relates to the technical field of electronic element machining. The auxiliary equipment comprises a spot welding table, a rotating assembly, a fixing assembly, and a lighting assembly; the rotating assembly and the lighting assembly are both fixed to the spot welding table; the side, away from the spot welding table, of the rotating assembly is fixedly connected with the fixing assembly; the fixing assembly comprises an inner annular pipe, an outer annular pipe, first fasteners and second fasteners; the first fasteners are fixed to the inner annular pipe; and the second fasteners are fixed on the outer annular pipe. Air can be fed into airbag clamping blocks of the first fasteners and airbag clamping blocks of the second fasteners through the inner annular pipe and the outer annular pipe by an air compressor, the airbag clamping blocks can expand after being fed, and a circuit board can be clamped; the airbag clamping blocks are soft to prevent the circuit board from being crushed; and meanwhile, due to the fact that the number of the first fasteners and the number of the second fasteners are both four, four circuit boards can be simultaneously fixed, so that the working efficiency is greatly improved, and time and labor are saved.

Owner:伊依

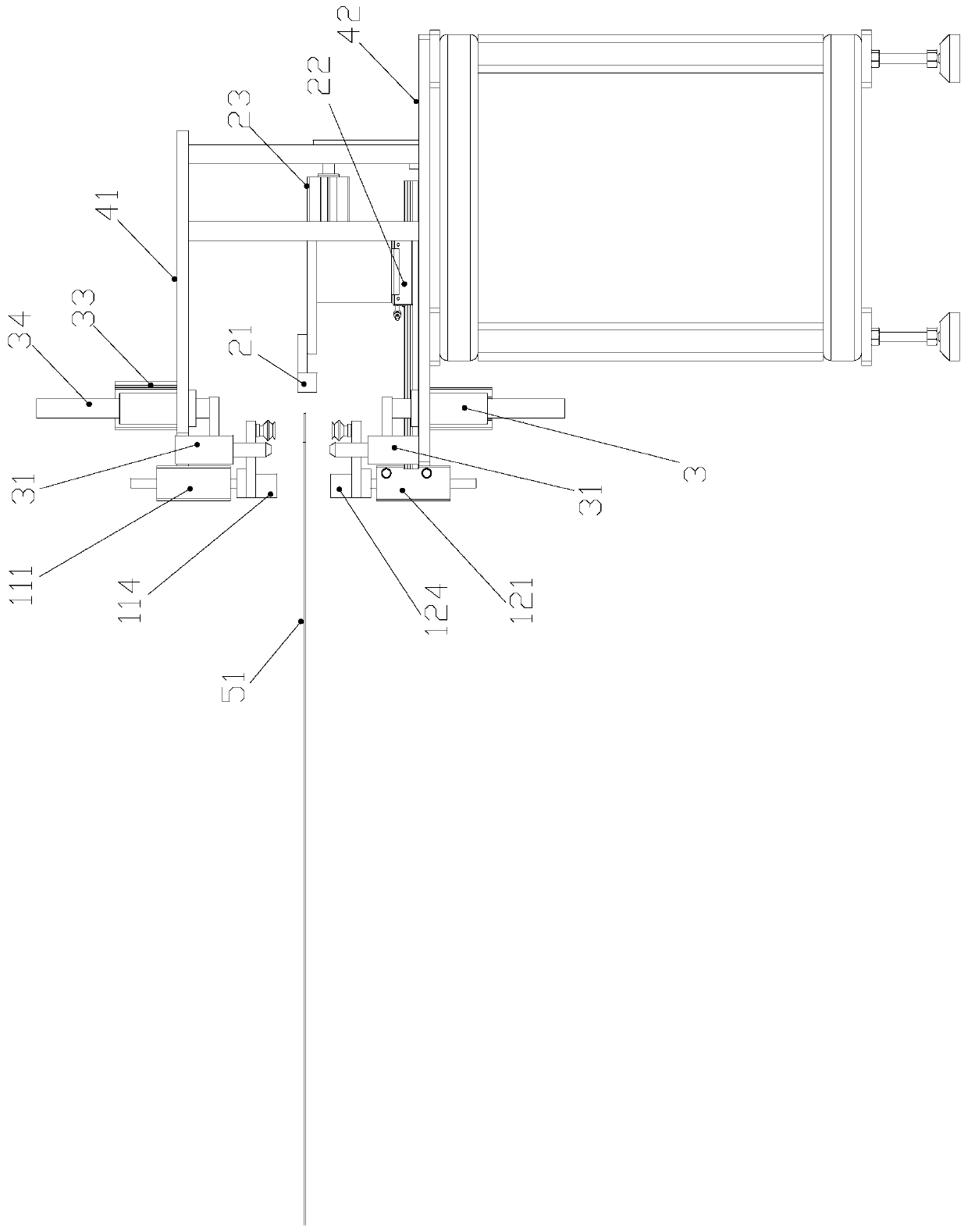

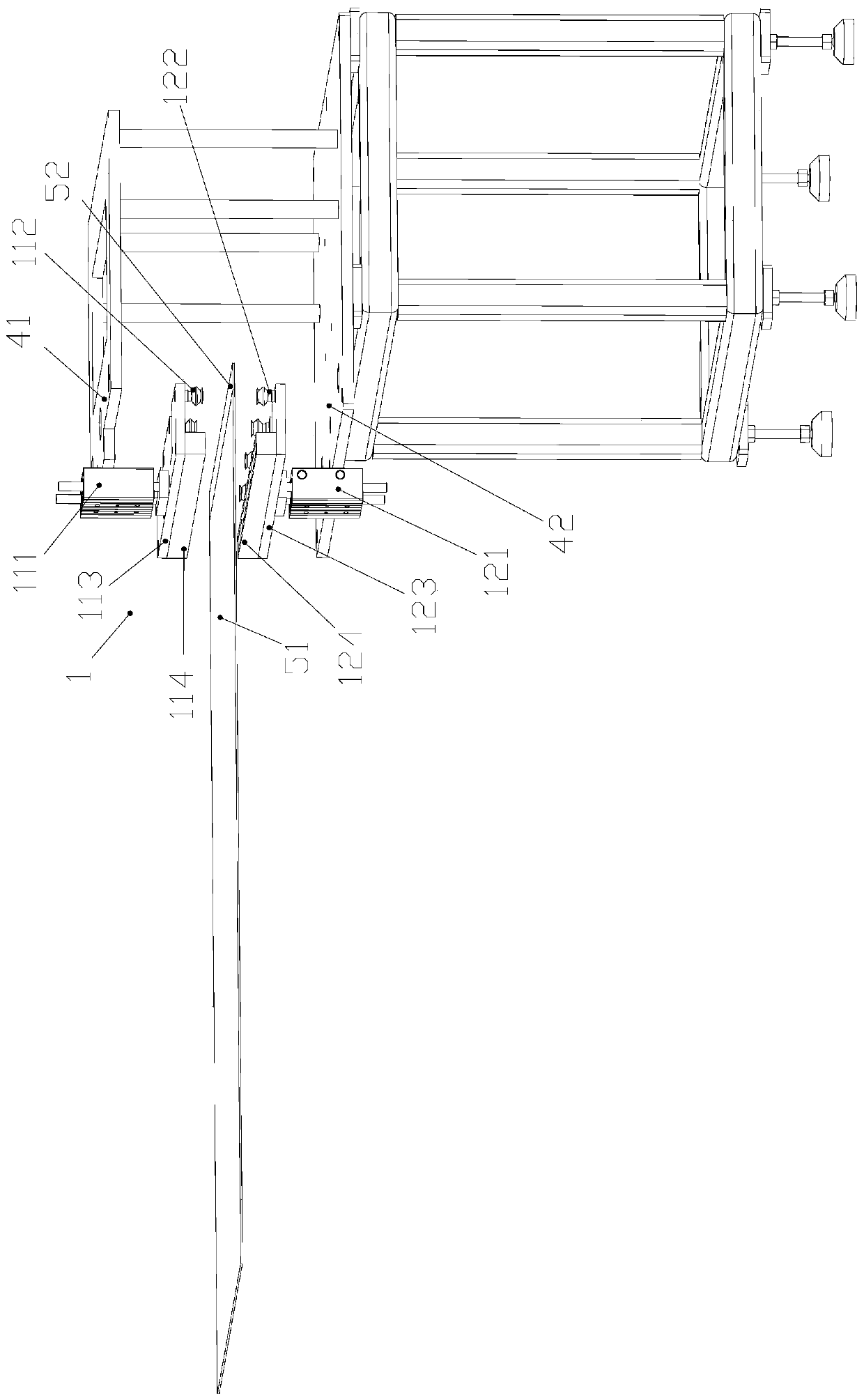

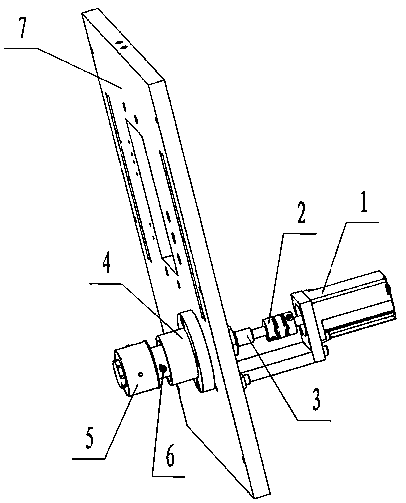

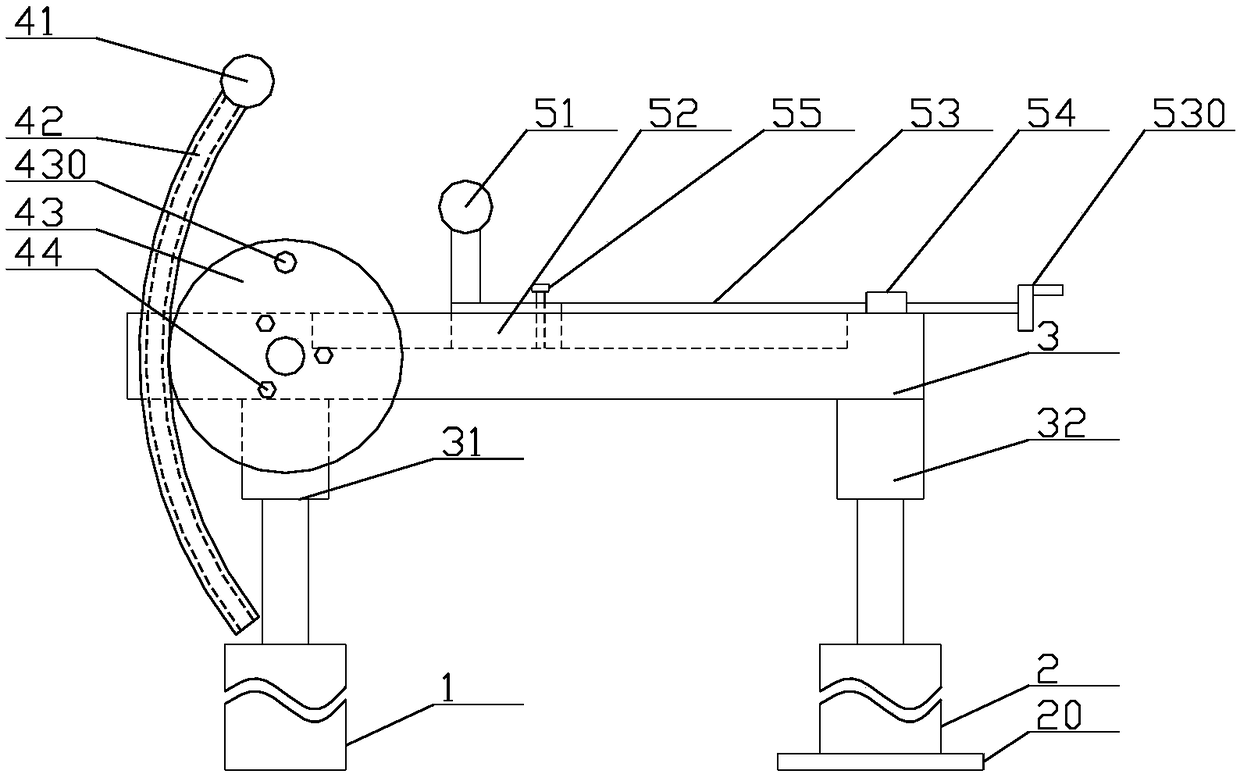

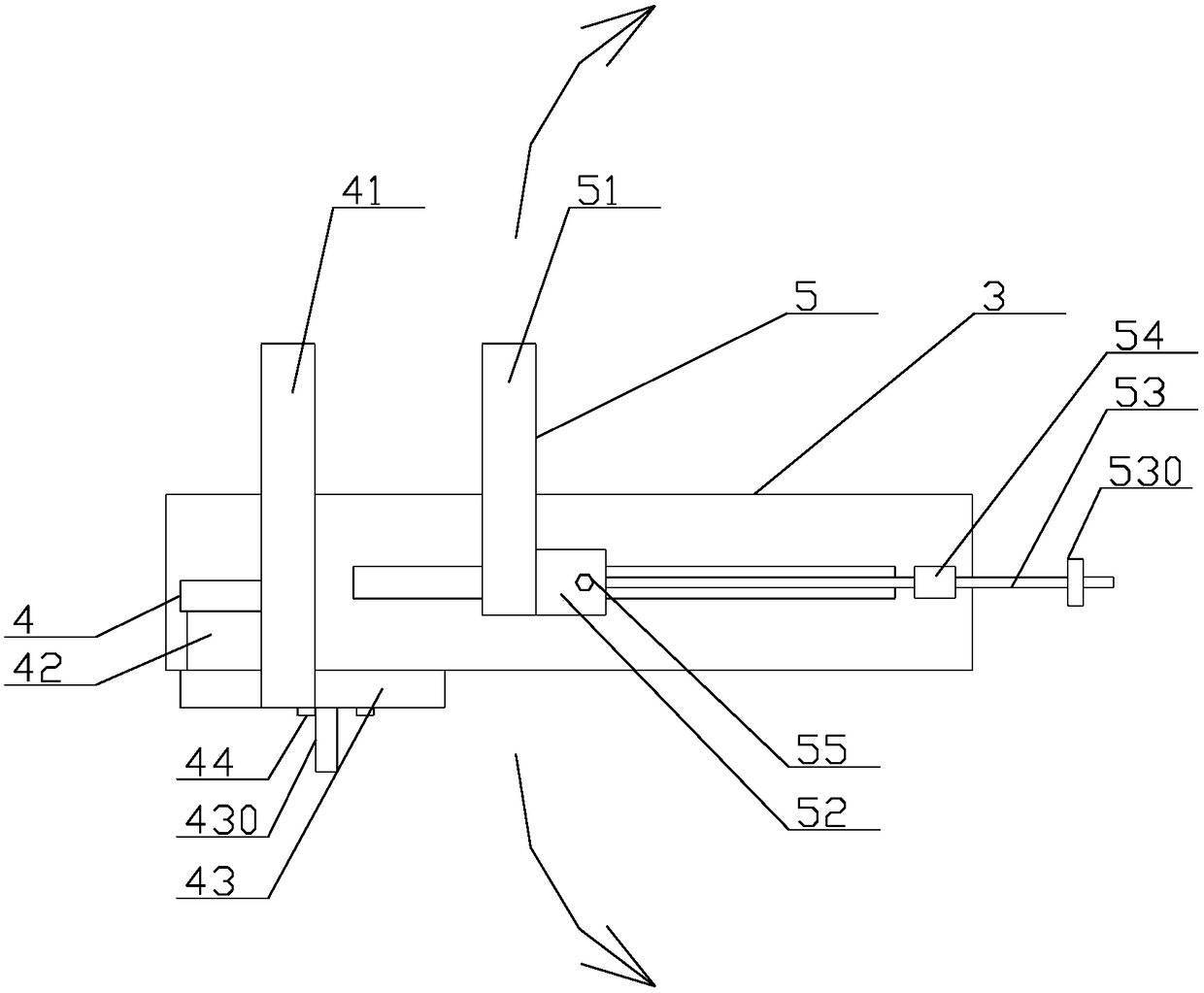

A spot welding station for auxiliary steel cylinder forming

ActiveCN106624587BExquisite structureImprove securityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

The invention relates to the field of machining equipment for coiling a steel plate, and discloses a spot welding table for assisting steel cylinder forming. The spot welding table for assisting steel cylinder forming is exquisite in structure, convenient to operate and good in stability, does not make direct contact with workers in use, and is very high in safety performance. The spot welding table comprises a first linear driving mechanism, a second linear driving mechanism, a worktable, an inner supporting assembly and an outer supporting assembly. The worktable is horizontally arranged, the bottom face of the work table is provided with a first connection cylinder and a second connection cylinder, the top end of the second linear driving mechanism penetrates into the second connection cylinder and is movably connected with the second connection cylinder, and the bottom end of the second linear driving mechanism is fixedly connected with the ground; bottom wheels are hinged to the bottom end of the first liner driving mechanism, a chassis is fixedly connected with the bottom end of the second linear driving mechanism, and the chassis is fixedly connected with the ground. The spot welding table has the advantages that operation is convenient, stability is good, and the safety performance is very high because the workers do not make contact with the spot welding table as a whole.

Owner:扬州鼎运电气设备有限公司

Brain electrode connector

InactiveCN113612052AModerate clamping forceEasy to plug and unplugSecuring/insulating coupling contact membersCoupling contact membersSpot weldingTitanium alloy

The invention relates to the technical field of medical instruments, in particular to a brain electrode connector. The brain electrode connector comprises an electrode shell connected with an electrode and a cable shell connected with a cable, a plurality of terminal grooves used for clamping terminals are formed in the electrode shell, and a circuit board and a card are arranged in the cable shell; the card is arranged in a card groove in the cable shell and comprises an open clamping end and a connecting end connected with the circuit board, and the opening clamping end of the card has certain elasticity and clamps at the two sides of the terminal. The brain electrode connector is suitable for the transmission of tiny signals and has the effects of moderate clamping force, convenience in plugging and unplugging and stable contact; a multichannel wire can control the distance between the adjacent card and the terminal through the clamping groove of the shell, and the requirement for smaller-size connection of the multichannel electrode can be met; meanwhile, the terminal can be made of stainless steel, titanium alloy and other materials, and spot welding is facilitated; and the terminal also can be made of the materials, such as copper alloy, etc., and adopts the tin soldering; and the card is made of beryllium copper and is good in elasticity and long in service life.

Owner:CHANGZHOU RUISHENAN MEDICAL DEVICES

An electric soldering iron device that facilitates the installation of electronic components

ActiveCN108044219BEasy to installDoes not slow down joinsSoldering ironElectronic componentMachining

The invention relates to the technical field of electronic component machining, and discloses an electric soldering iron device for convenient installation of electronic components. The electric soldering iron device includes a shell body, a wiring tube is fixedly connected at the right side of the shell body, and a fixing column is fixedly connected at the right side of an inner cavity of the shell body; and the left side of the fixing column is provided with a soldering iron core which penetrates through and extends out of the left side of the shell body in a connecting mode, the right sideof the inner cavity of the shell body is fixedly provided with connecting wires which are located at the upper and lower sides of the fixing column in a connecting mode, and the left side of the connecting wires and the right side of the soldering iron core are fixedly connected. According to the electric soldering iron device for convenient installation of the electronic components, by arranginga first sliding rod, a second sliding rod, a first sliding groove, a second sliding groove, a first support rod, a second support rod, a pushing plate and a heater band and by moving the pushing plateto the left or right to enable a soldering iron body to move to the left or right, the position of a soldering iron bit can be regulated, and further the welding spot can be convenient when the electric components are installed to meet the dead angle position.

Owner:南通西东电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com