Metal sheet grounding three lead surface mount quartz resonator and production technology thereof

A quartz resonator and production process technology, applied in electrical components, impedance networks, etc., can solve problems such as IC damage and crystal failure to work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

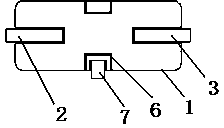

[0037] In the surface-mounted quartz resonator with three lead wires grounded by metal sheets in this embodiment, the third lead wire is the metal sheet 7 , and the metal sheet 7 does not pass through the insulating spacer 4 . The production process of the quartz resonator is as follows:

[0038] (1) Making sheet metal parts:

[0039] Both sides of the metal sheet are jagged, the end of the metal sheet is the part to be spot welded, the thickness is 0.4mm, which is less than the thickness of the insulating gasket, the connection between the metal sheet and the material is the punching position, the thickness is 0.1mm, chemical plating Finally, put it into the corresponding position of the spot welding metal sheet jig.

[0040] (2) Make insulating gaskets different from the prior art structure, such as Figure 3-5 shown.

[0041] The insulating spacer 4 is rectangular, and its two ends are provided with grooves 5 adapted to the first lead 2 and the second lead 3 in the brack...

Embodiment 2

[0047] The metal sheet grounded three-lead surface-mounted quartz resonator of this embodiment is basically the same in structure and production process as in Example 1, the difference being that in step (5), the metal sheet material is placed on the spot welding metal sheet jig , the end of the metal sheet is placed in the notch of the insulating gasket. Cover the pressure plate, dispense the metal sheet material on the bottom plate of the quartz crystal resonator, and put it in an oven or tunnel furnace to dry.

[0048] From the perspective of saving production costs, on the basis of the above embodiments, the distance between the metal sheets on the metal sheet material can be 1 / 2 of the distance between the notches of adjacent insulating spacers in the spot welding metal sheet jig. This spacing design can make the metal sheet separate from the metal sheet material, and the metal sheet material can be put into the spot welding metal sheet jig for secondary use, which maximi...

Embodiment 3

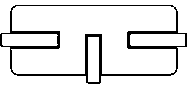

[0050]The structure of the metal sheet grounded three-lead surface-mounted quartz resonator of this embodiment is basically the same as that of Embodiment 1, but the structure of the metal sheet in this embodiment is different from the linear metal sheet structure in Embodiment 1 and Embodiment 2. The sheet is z-shaped, such as Figure 8-9 shown. The production process is basically the same as that in Example 1, the difference is that in step (1) a metal sheet material compatible with the metal sheet structure is made, and in step (5) the z-shaped upper plane end of the metal sheet is spot-welded or glued Fixed on the shell of the surface mount quartz resonator, the z-shaped lower plane is located on the same plane as the bottom surface of the insulating gasket 4, and cut along the connection between the metal sheet and its material to form a three-lead surface mount quartz crystal resonator.

[0051] Preferably, a metal sheet is fixed on the surface-mounted quartz resonator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com