A spot welding station for auxiliary steel cylinder forming

A spot welding and steel cylinder technology, applied in auxiliary welding equipment, auxiliary devices, welding/cutting auxiliary equipment, etc., can solve the problems of inability to complete butt joint, hidden safety hazards, difficulty in operation and increased labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

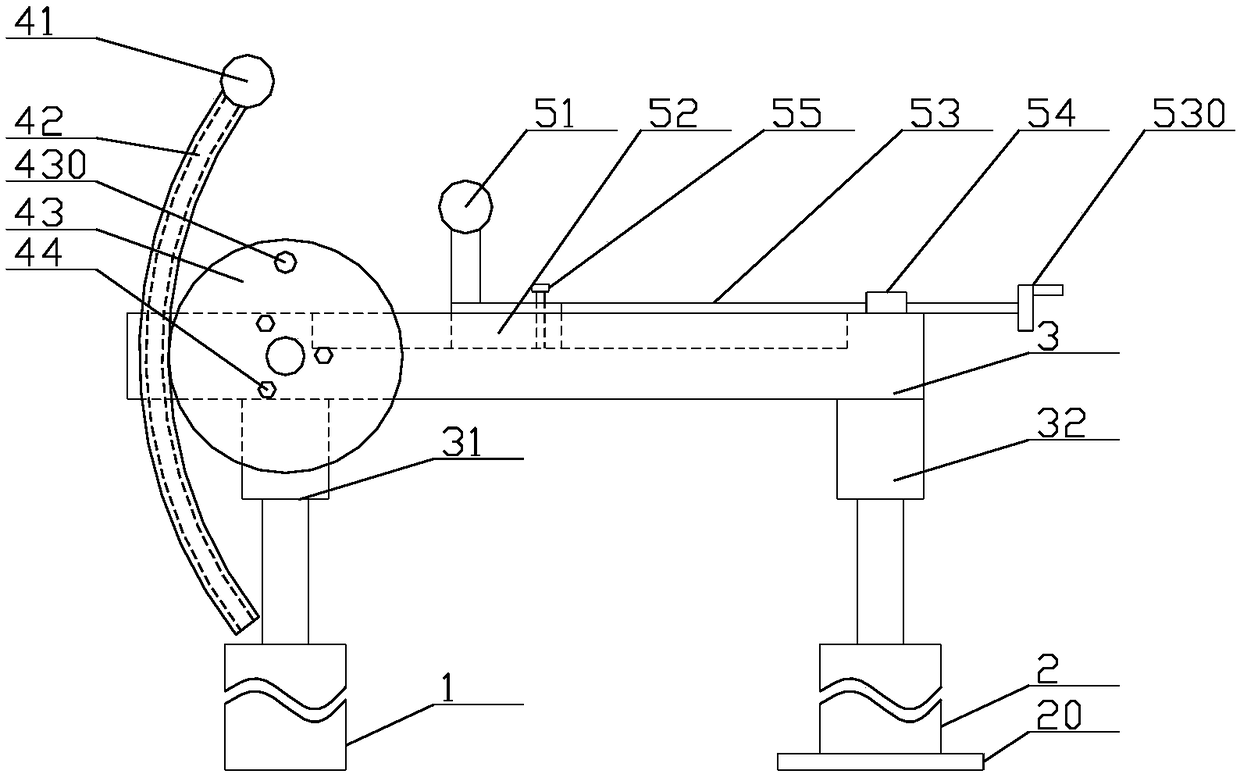

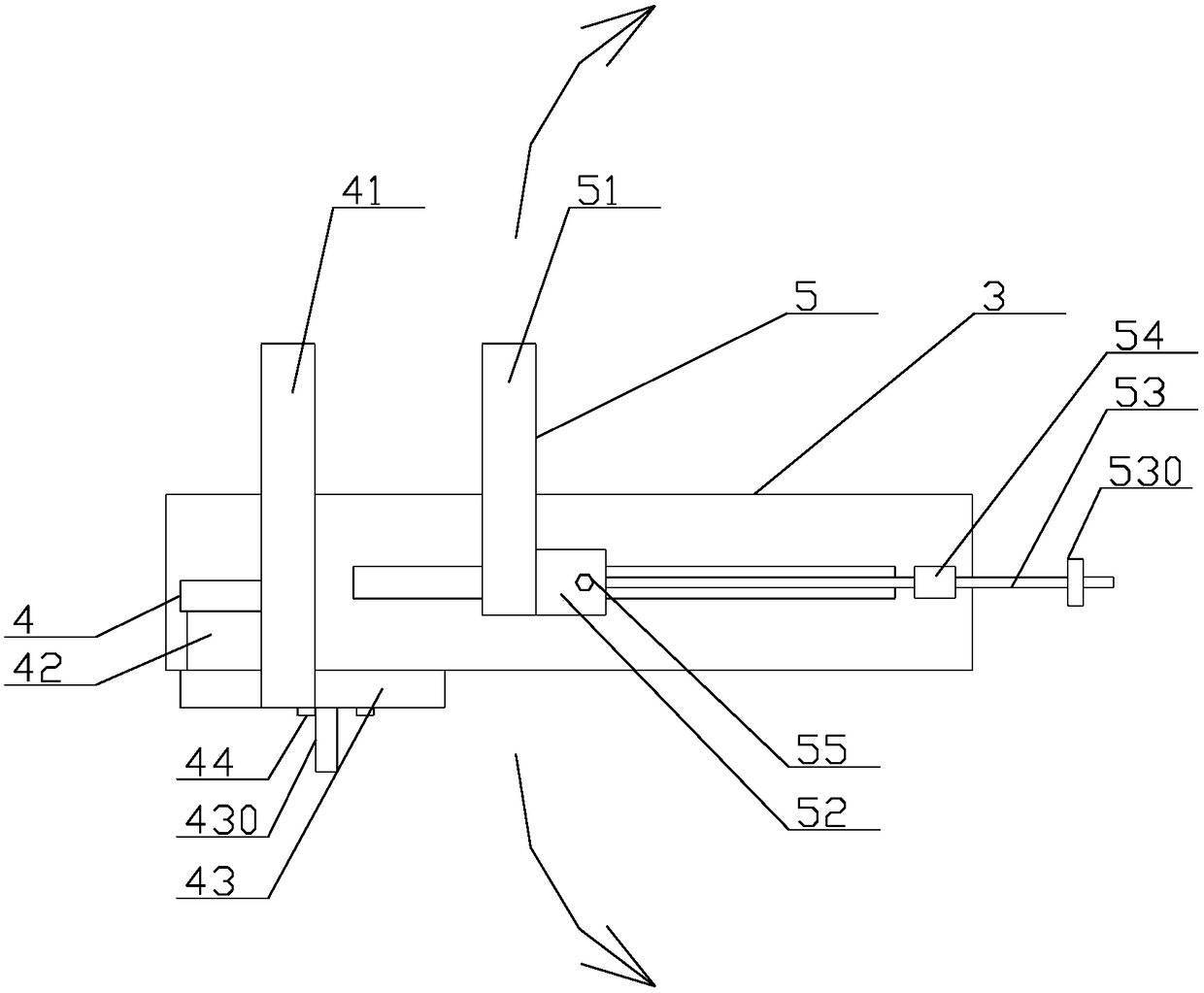

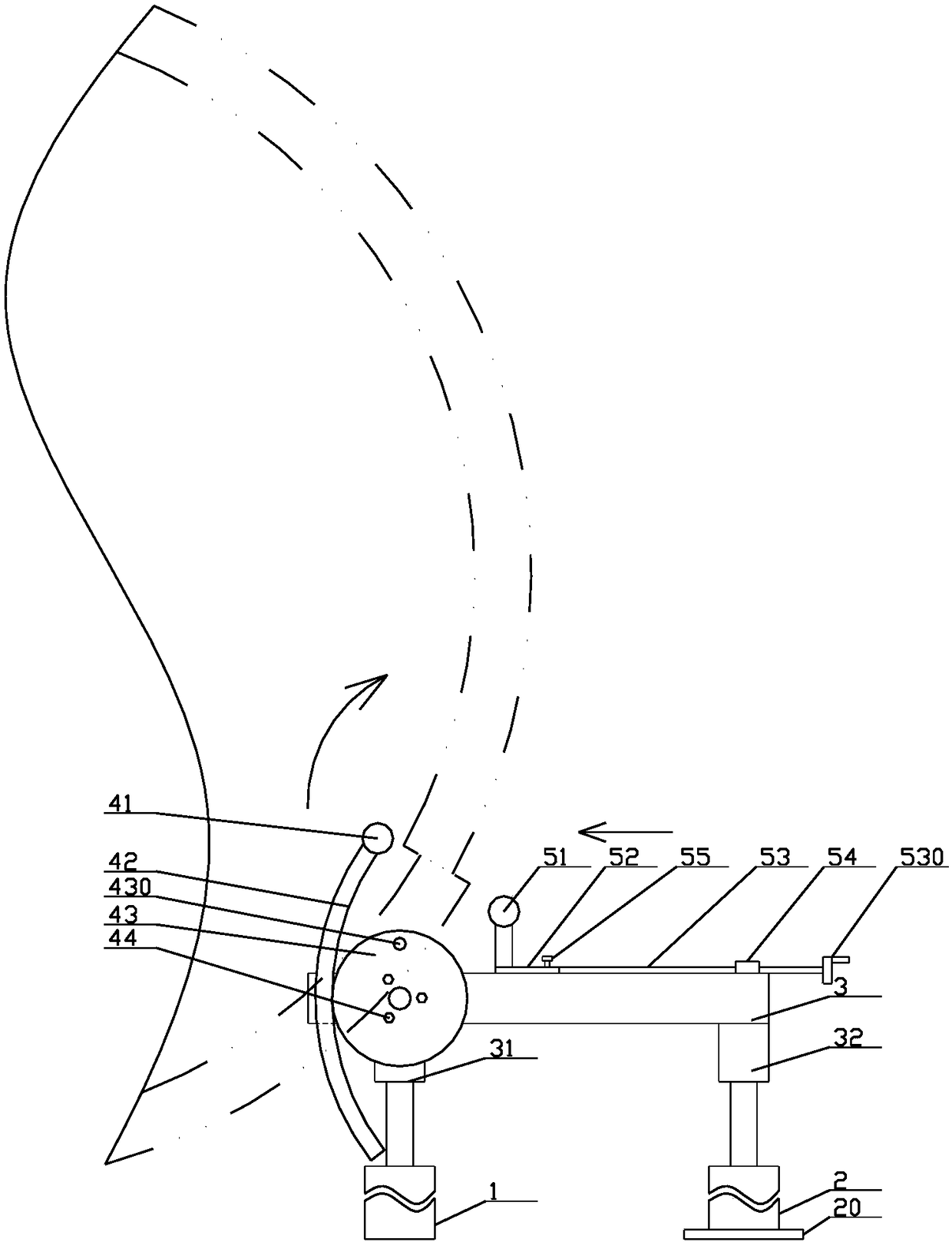

[0023] The present invention as Figure 1-4 As shown, it includes a linear drive mechanism 1, a linear drive mechanism 2, a workbench 3, an inner support assembly 4 and an outer support assembly 5. The workbench 3 is horizontally arranged, and its bottom surface is provided with a connecting cylinder 1 31 and a connection Cylinder two 32, the top end of the linear drive mechanism two 2 is pierced in the connecting cylinder two 32, and is movably connected with the connecting cylinder two 32, the top end of the linear driving mechanism one 1 is pierced in the connecting cylinder one 31, and is fixedly connected with the connecting cylinder 1 31, the bottom end of the linear drive mechanism 2 2 is fixedly connected with the ground; when in use, the inner support assembly can enter or exit the steel cylinder through the rotating workbench;

[0024] The inner support assembly 4 includes an inner support roller 41, an arc guide rail 42, a drive plate 43, a hinge shaft and at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com