Auxiliary equipment for spot welding of electronic elements

A technology of auxiliary equipment and electronic components, applied in welding/cutting auxiliary equipment, auxiliary welding equipment, welding equipment, etc. The effect of stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

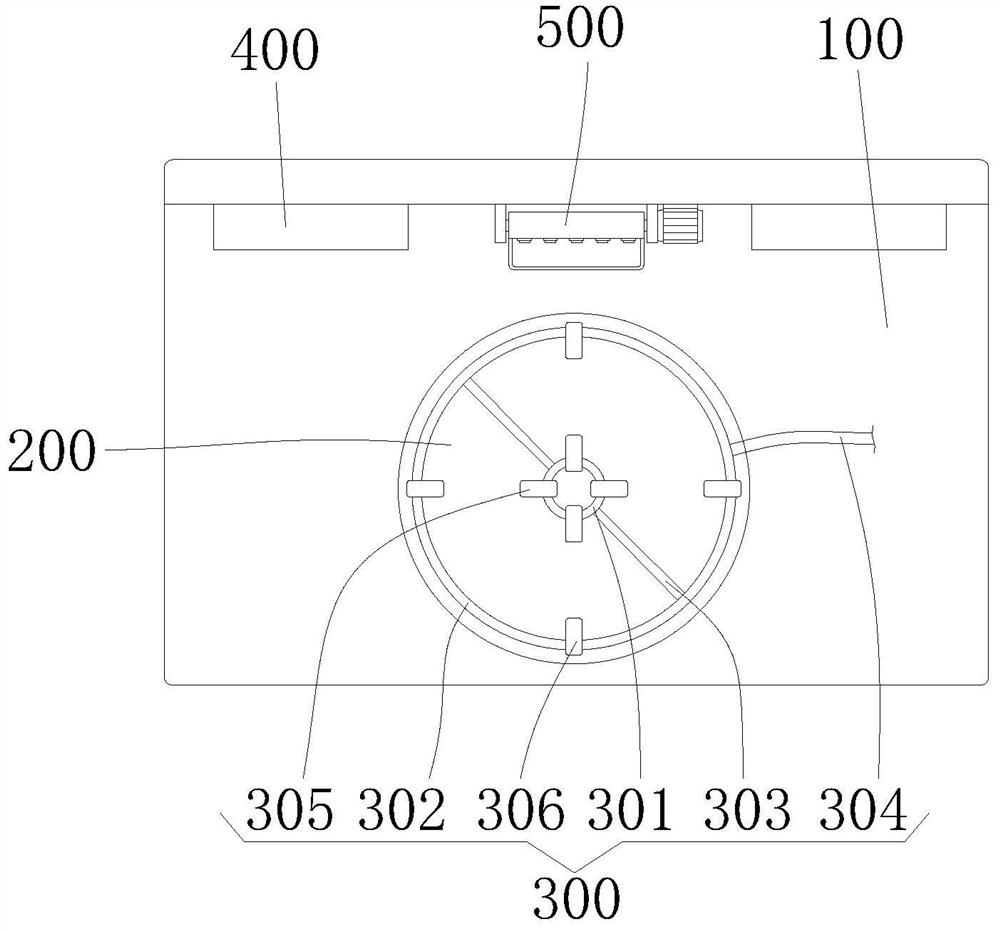

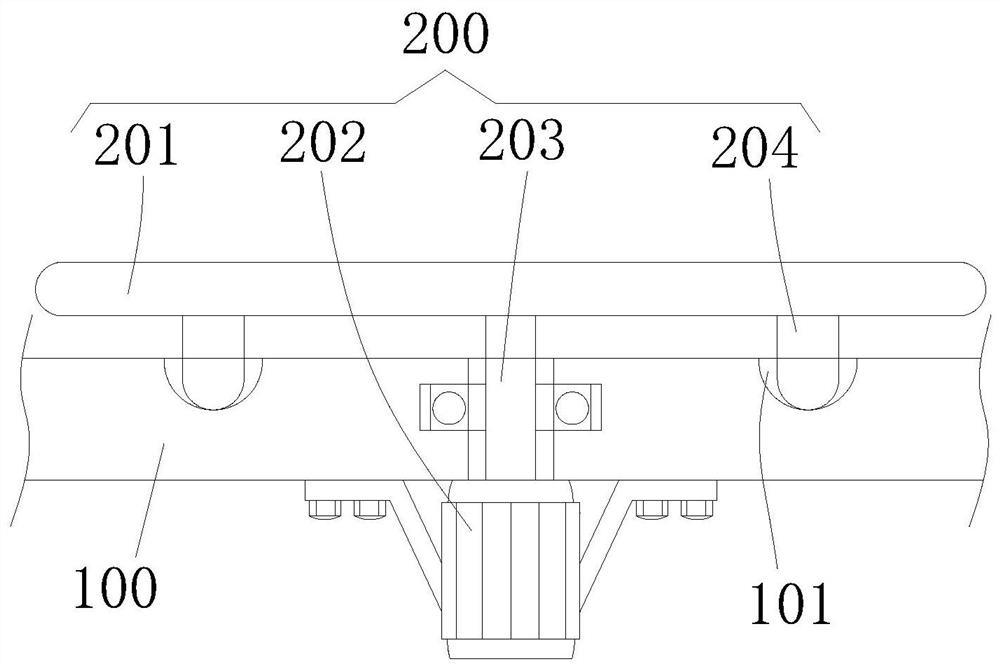

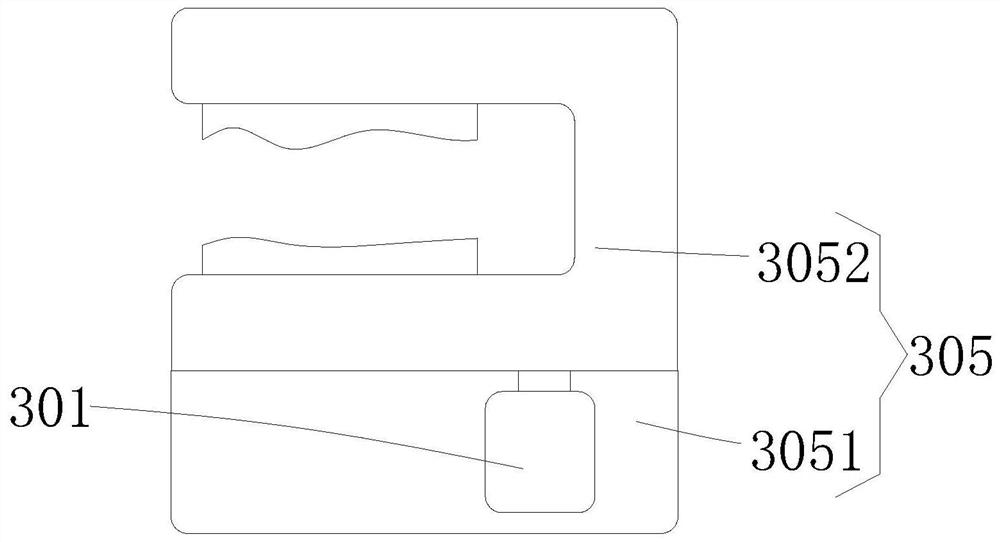

[0026] see figure 1 , the present invention is an auxiliary equipment for spot welding of electronic components, comprising a spot welding station 100, a rotating assembly 200, a fixed assembly 300 and a lighting assembly 500, the rotating assembly 200 and the lighting assembly 500 are fixed on the spot welding station 100, and rotate The side of the assembly 200 away from the spot welding station 100 is fixedly connected to the fixing assembly 300 , and the spot welding station 100 is symmetrically fixed with a shelf 400 through which spot welding tools can be stored.

[0027] Among them such as figure 1 and 2 As shown, the rotating assembly 200 includes a turntable 201, a first motor 202 and a first rotating shaft 203, the first motor 202 is fixed on the spot welding table 100, and the output end of the first motor 202 is rotationally connected with the turntable 201 through the first rotating shaft 203, The first motor 202 can drive the turntable 201 to rotate through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com