Spot welding equipment for lithium battery gasket

A technology of spot welding equipment and lithium batteries, which is applied in the direction of resistance welding equipment, welding equipment, secondary batteries, etc., can solve the problems of high defective rate, low practicability, poor clamping effect, etc., and achieve firm fixation , The effect of convenient spot welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

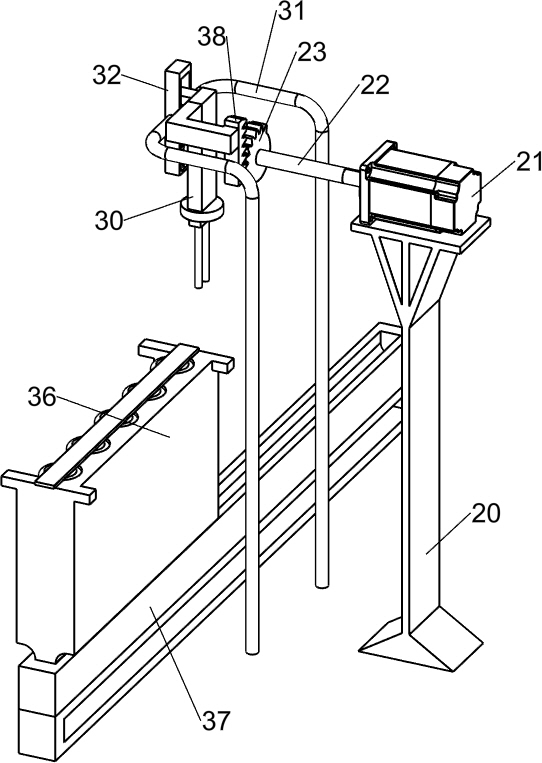

[0087] A kind of spot welding equipment for lithium battery gasket, such as figure 1 As shown, a base 1, a driving mechanism 2 and a spot welding mechanism 3 are included, the driving mechanism 2 is connected to the upper rear side of the base 1, and the spot welding mechanism 3 is connected to the upper rear side of the base 1.

[0088] When the device needs to be used, the user can evenly place multiple batteries in the spot welding mechanism 3, place the welding rod on the upper side of the spot welding mechanism 3, start the driving mechanism 2, and when the driving mechanism 2 forwards to the spot welding mechanism When the three phases are in contact, the spot welding mechanism 3 is driven to move downward to achieve the purpose of spot welding the lithium battery gasket. Under the action of resetting, the spot welding mechanism 3 is driven to move upwards to the original position. After the operation is finished, the driving mechanism 2 is closed, and when used again, t...

Embodiment 2

[0090] On the basis of Example 1, such as figure 2 As shown, the driving mechanism 2 includes a support base 20, a servo motor 21, a first rotating shaft 22 and a first missing gear 23, the support base 20 is connected to the upper rear side of the base 1, and the servo motor 21 is connected to the top side of the support base 20. The output shaft of the motor 21 is connected with a first rotating shaft 22 , and the front end of the first rotating shaft 22 is connected with a first missing gear 23 .

[0091] When the user places the welding rod on the upper side of the spot welding mechanism 3, start the servo motor 21, the forward rotation of the servo motor 21 drives the first rotating shaft 22 forward rotation, and the forward rotation of the first rotating shaft 22 drives the first missing gear 23 forward rotation, to achieve For the purpose of providing driving force for the equipment, when the first missing gear 23 rotates forward to contact with the spot welding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com