Fixing support of spot welding nickel sheet of mobile battery

A mobile battery, battery fixing technology, applied in resistance welding equipment, battery pack components, circuits, etc., can solve the problems of inconvenient welding methods and easily affected spot welding accuracy, and achieve precise spot welding and spot welding accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

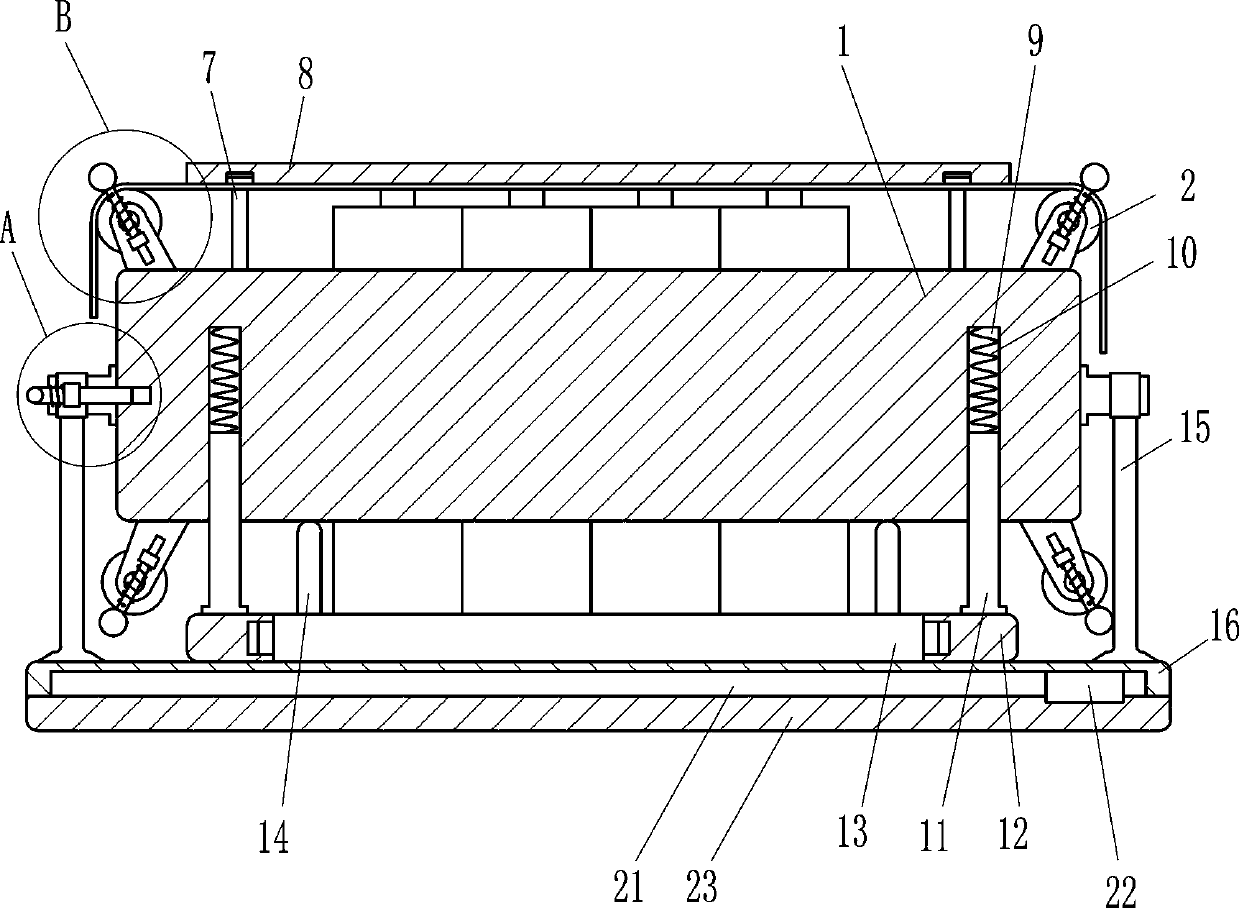

[0022] A mobile battery spot welding nickel sheet fixing frame, such as figure 1 , 2 , 3 and 4, including a first splint 1, a backing wheel 2, a battery fixing assembly, a battery positive support assembly, a battery negative support assembly, and a support fixing assembly, and pads are provided on the top and bottom left and right sides of the first splint 1 Wheel 2, the rear side of the first splint 1 is provided with a battery fixing assembly that fixes the battery through rotation. A battery negative pole supporting assembly is installed to support the negative pole of the battery in a supporting manner, and a supporting and fixing assembly is provided in the middle of the first splint 1 for supporting by rotating and fixing by sliding.

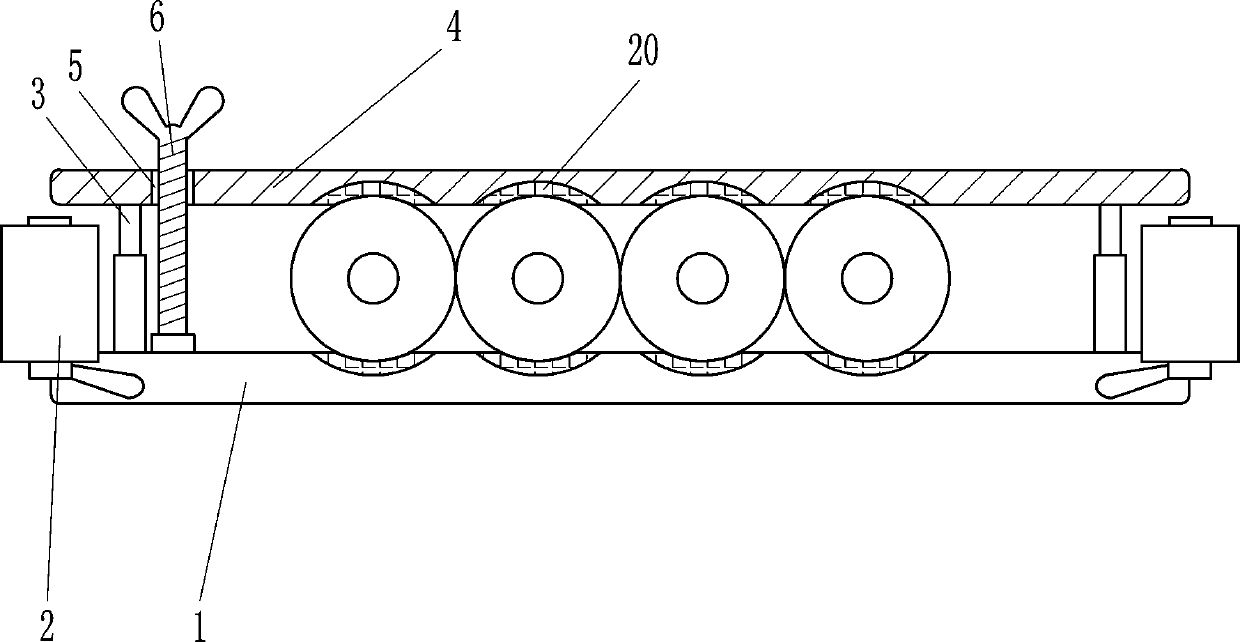

[0023] like figure 2 As shown, the battery fixing assembly includes a telescopic rod 3, a second splint 4 and a bolt 6, the rear side of the first splint 1 is welded with a telescopic rod 3 on both sides, and the rear end of the telesc...

Embodiment 2

[0033] On the basis of Example 1, such as figure 2 As shown, in order to better protect the battery, rubber pads 20 are also included, and four rubber pads 20 are provided on the rear side of the first splint 1 and the front side of the second splint 4 .

[0034] like figure 1 and 2As shown, in order to better use the device, it also includes a slider 22 and a support plate 23, a second chute 21 is opened at the bottom of the base 16, and a slider 22 is slidably connected to the second chute 21, and the slider 22 The bottom is fixedly connected with a support plate 23 by screws.

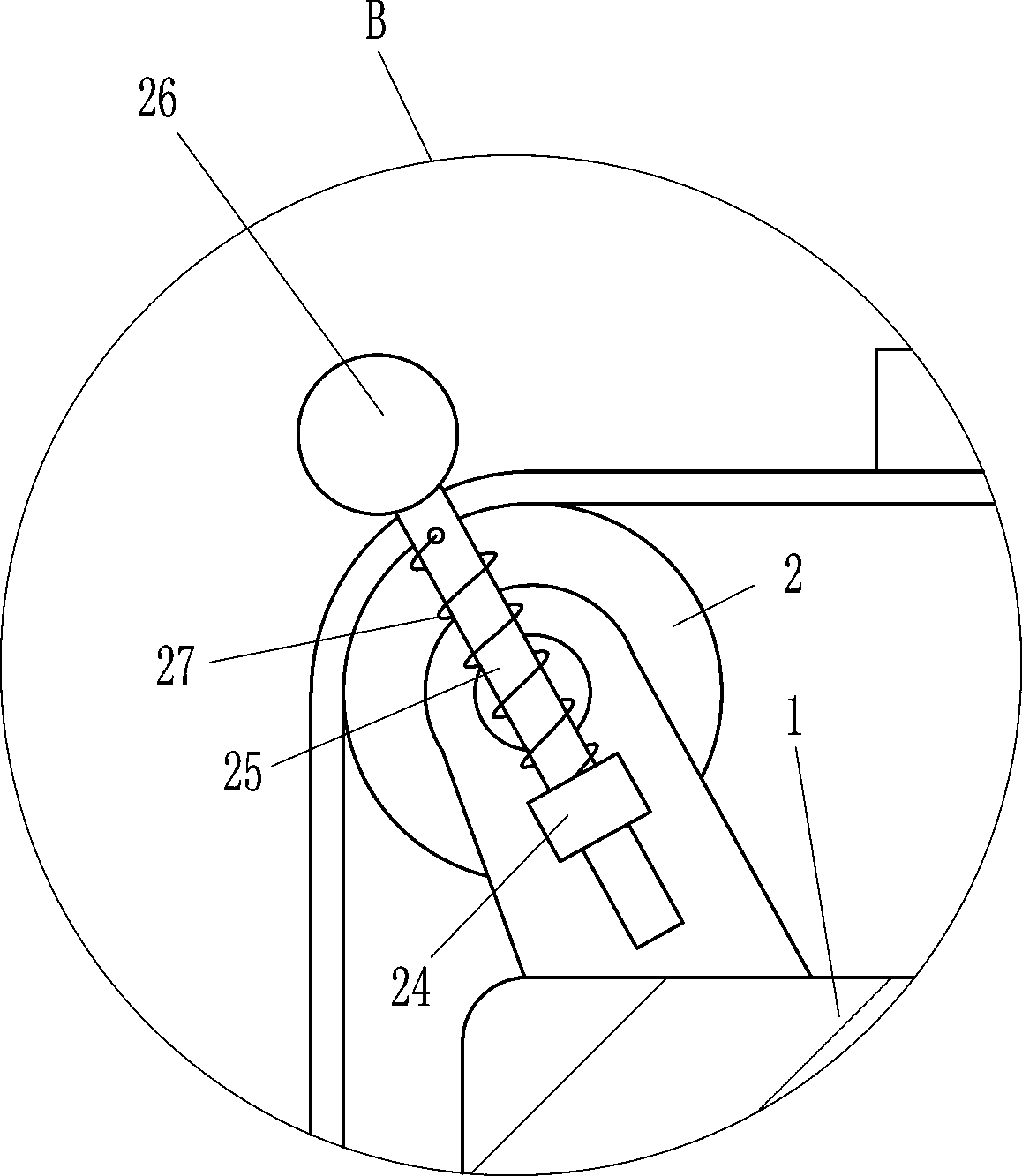

[0035] like figure 1 , 3 As shown in and 5, in order to carry out spot welding to battery nickel sheet more accurately, also comprise guide sleeve 24, guide rod 25, pressure bar 26 and the 3rd spring 27, backing wheel 2 front sides are all provided with guide sleeve 24, guide All sliding type is connected with guide rod 25 in the cover 24, and guide rod 25 outer ends are connected with depressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com