Long-service small-sized electromagnetic relay

An electromagnetic relay, long-life technology, applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., can solve the problems of many production organization procedures, low work efficiency, unfavorable automatic assembly, etc., to improve creepage distance and insulation, Improve processing quality and efficiency, and facilitate automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The long-life small electromagnetic relay provided by the embodiment of the present invention has a compact product structure, clearer functional area separation, stable performance, and good insulation, can effectively avoid relay failure caused by excessive pull-in voltage, and has high assembly positioning accuracy. And easy to realize automated assembly.

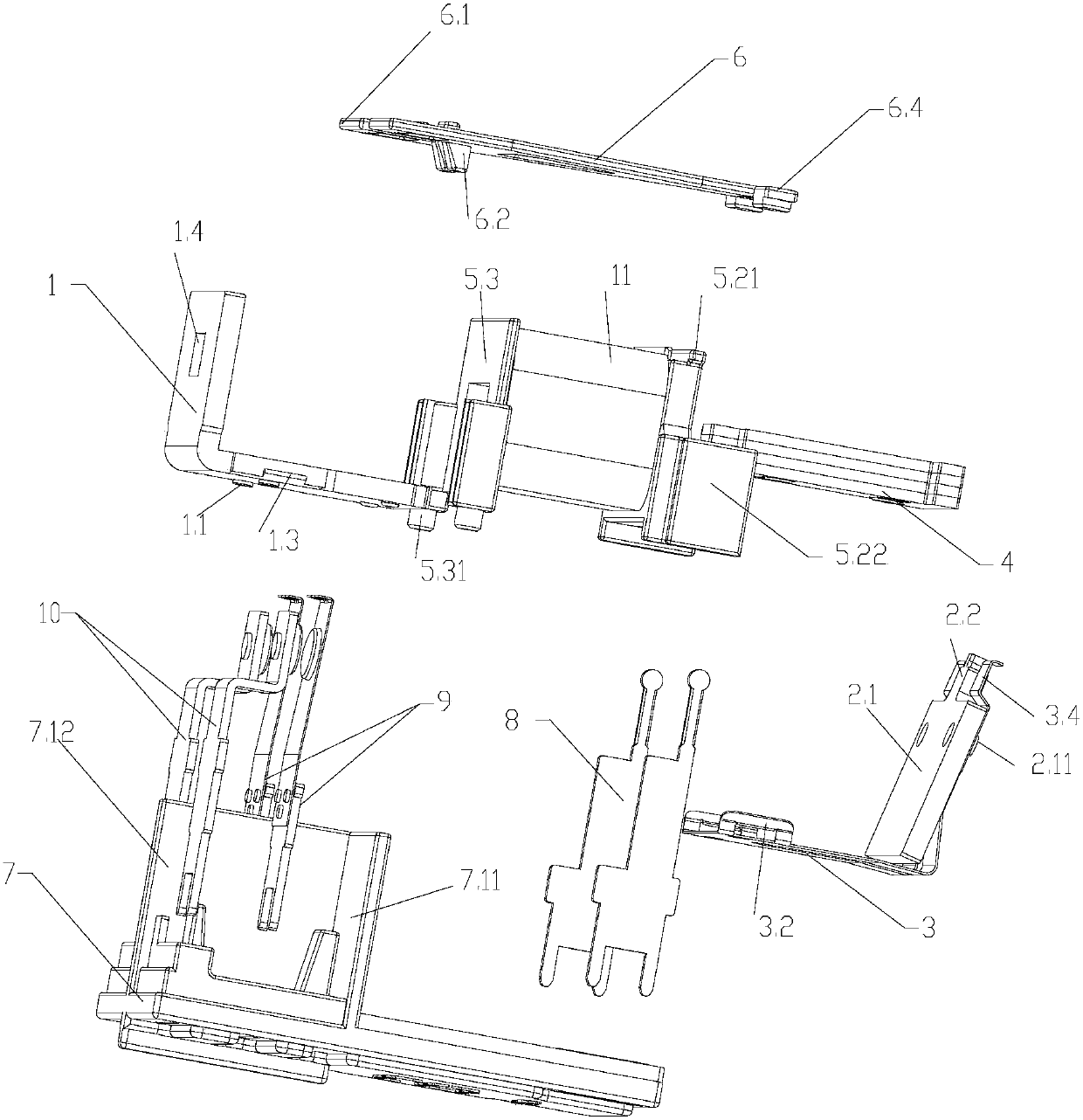

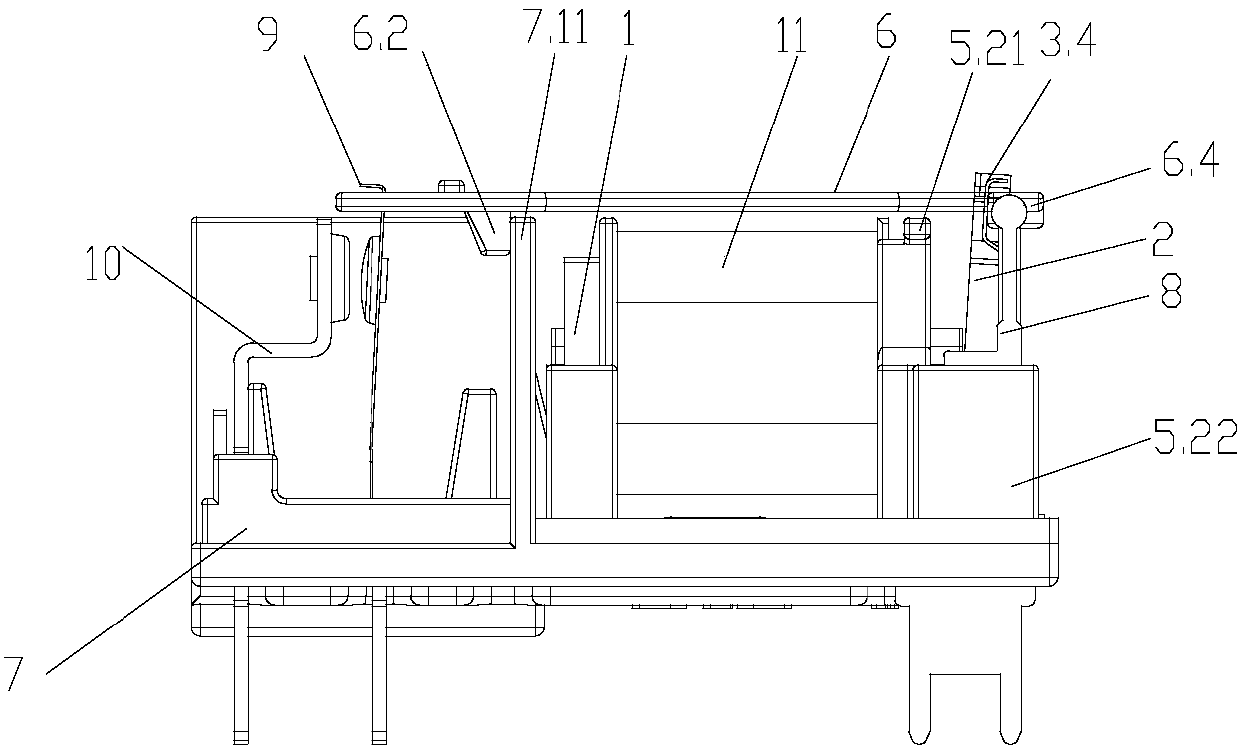

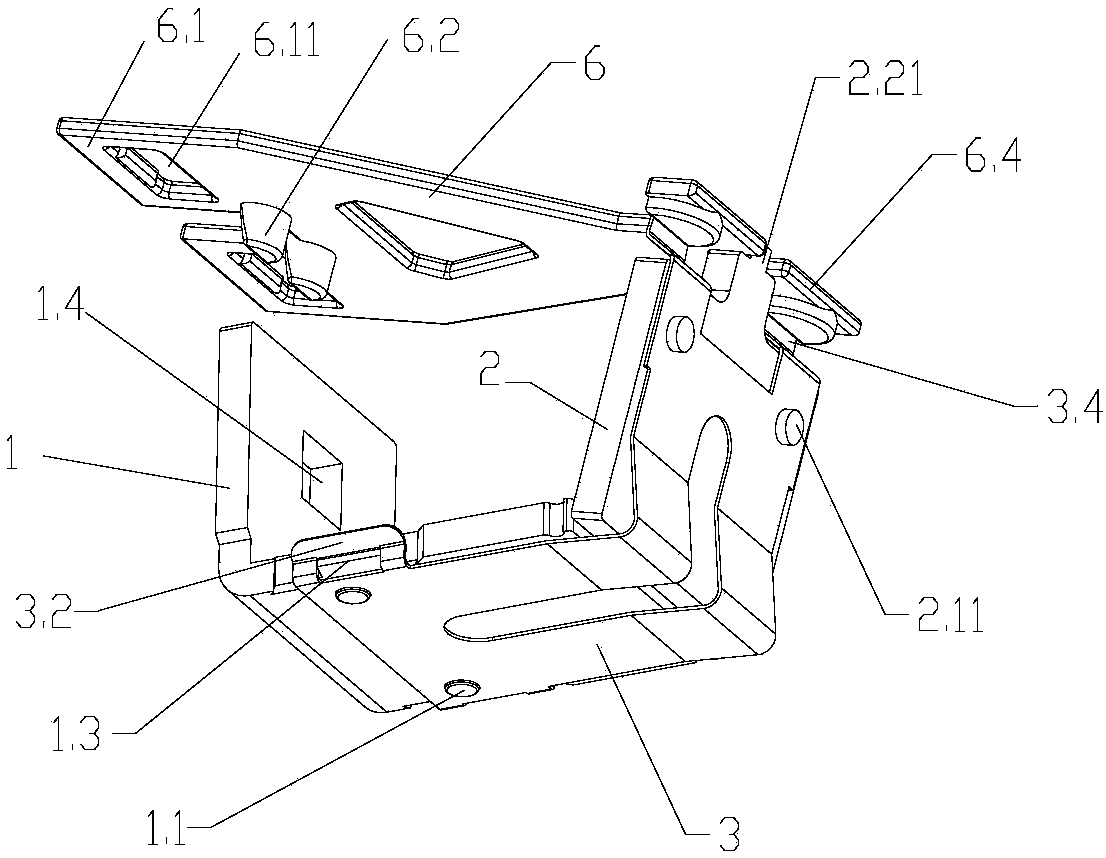

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a long-life small electromagnetic relay includes a yoke 1, an armature 2, a shrapnel 3, an iron core assembly 4, a coil frame 5, a push rod 6 and a base 7, wherein the base 7 is provided with a "T-shaped" insulating wall 7.1. Divide the base into the conductive system area and the magnetic circuit system area. The "reverse L-shaped" shrapnel 3 is an integrated front and rear symmetrical structure, in which the two armature riveting holes 3.1 in the vertical section and the two protruding outer walls of the armature 2 The shrapnel riveting terminal 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com