Machining fixture for turnover bracket

A technology for flipping brackets and fixtures, applied in the directions of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of lack of welding fixtures and inaccurate positioning in welding workshops, and achieve improved functional structure, simple device structure, and improved functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

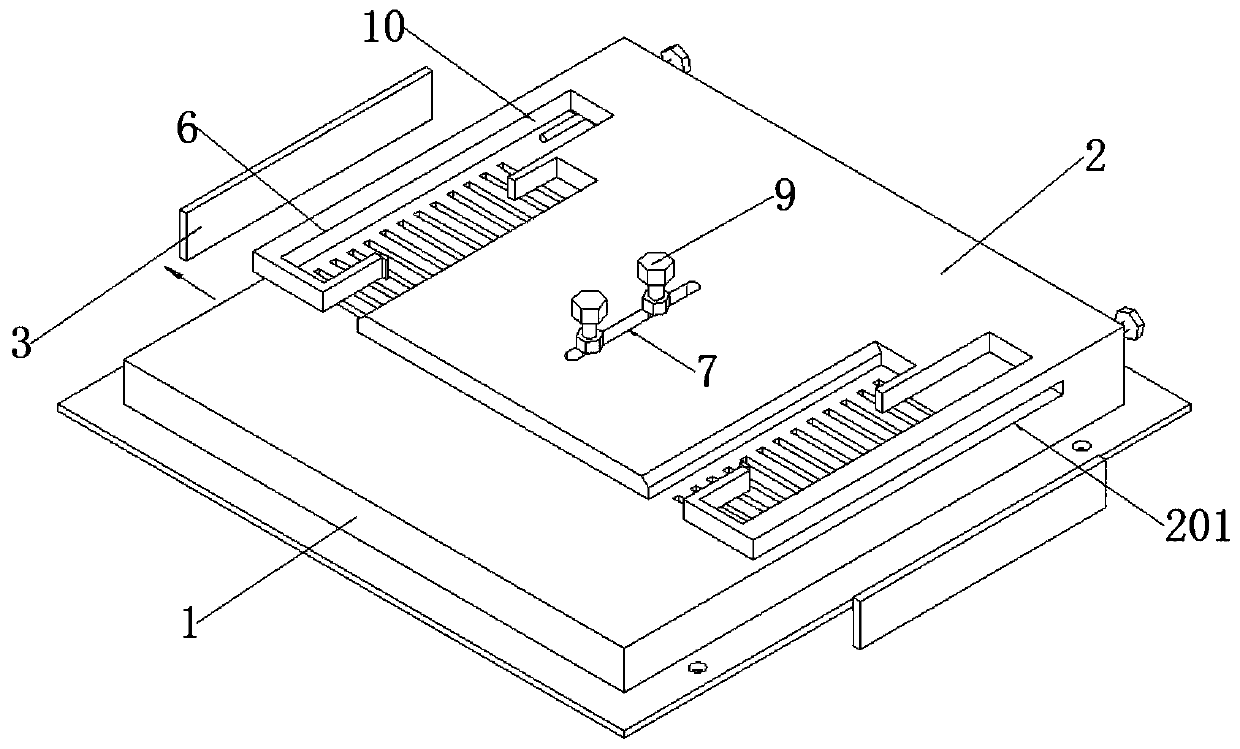

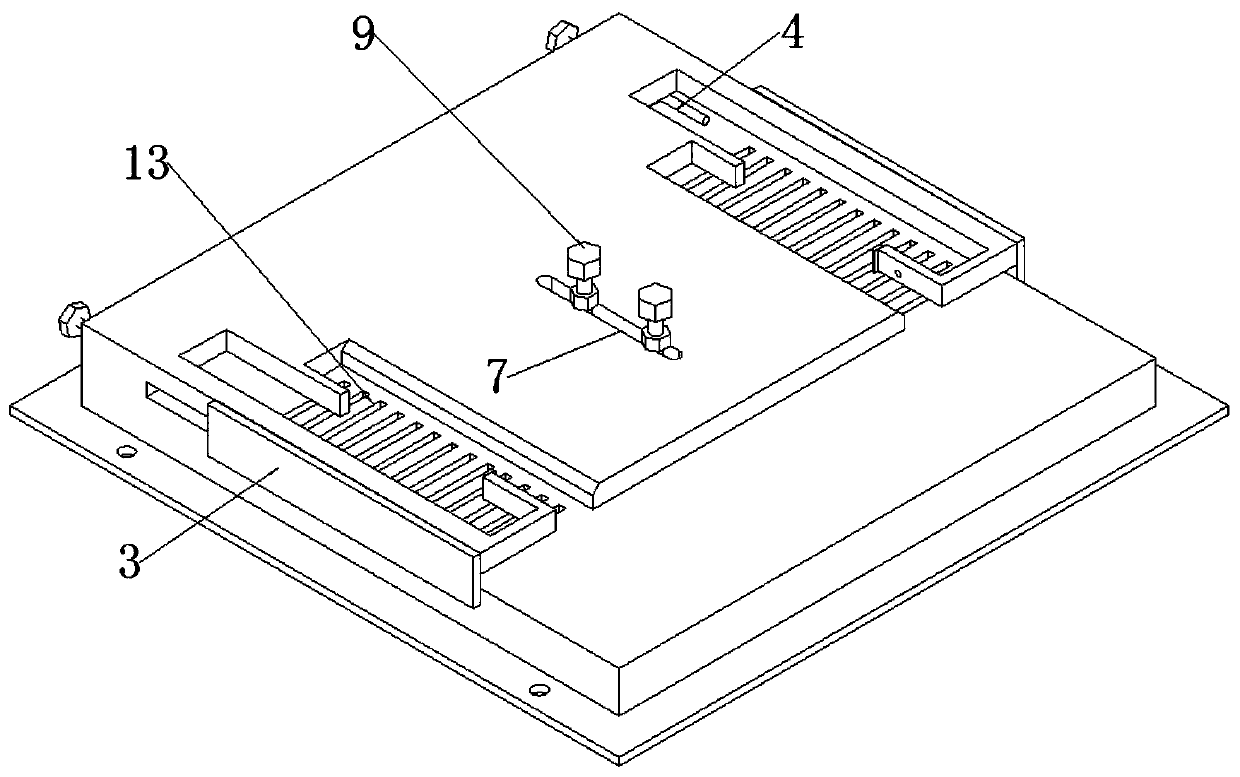

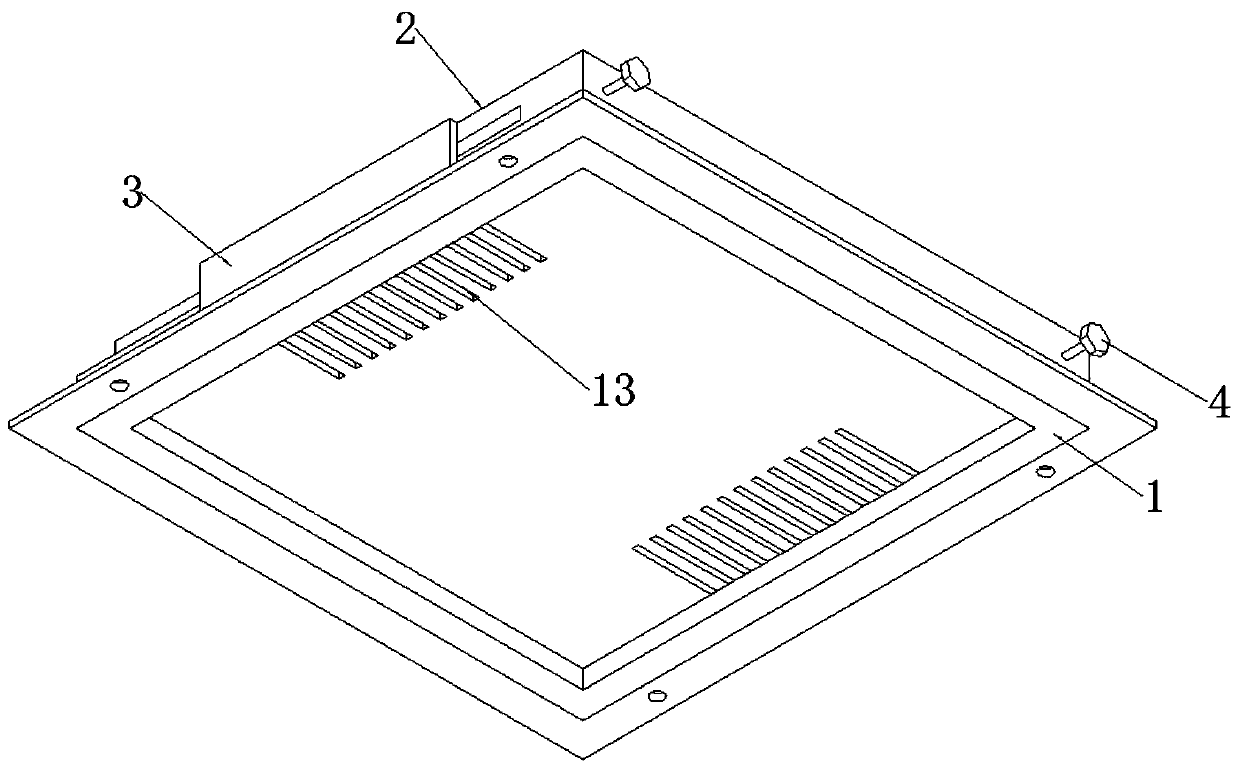

[0029] as attached figure 1 to attach Figure 7 Shown:

[0030] The invention provides a processing jig for a flip bracket, which includes a mounting base 1, a pressure plate 2, a pressure groove 201, a limit plate 3, a top bolt 4, a notch 5 in the left welding area, a notch 6 in the right welding area, and a middle notch 7 , welding nut 8, locking bolt 9, left vertical plate welding limit groove 10, right vertical plate welding limit groove 11, wipe seat 12 and drain groove 13; the mounting seat 1 is a square cavity structure, and its bottom surface has The mounting plate of the mounting hole; the top surface of the mounting seat 1 is provided with an upwardly tilted pressure plate 2, and the pressure plate 2 is parallel to the top surface of the mounting seat 1; the middle position of the pressure plate 2 is provided with a waist circular notch structure The middle notch 7, and two welding nuts 8 are welded on the middle notch 7, and two locking bolts 9 are threaded downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com