Battery bracket component and multi-section combined public bracket of cylindrical battery cells

A technology for battery brackets and components, which is applied to battery pack parts, electrical components, circuits, etc. It can solve the problems of weak battery integrity, high mold precision requirements, and a large number of brackets, so as to increase the cost of manual assembly, Quick assembly and disassembly, the effect of reducing mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

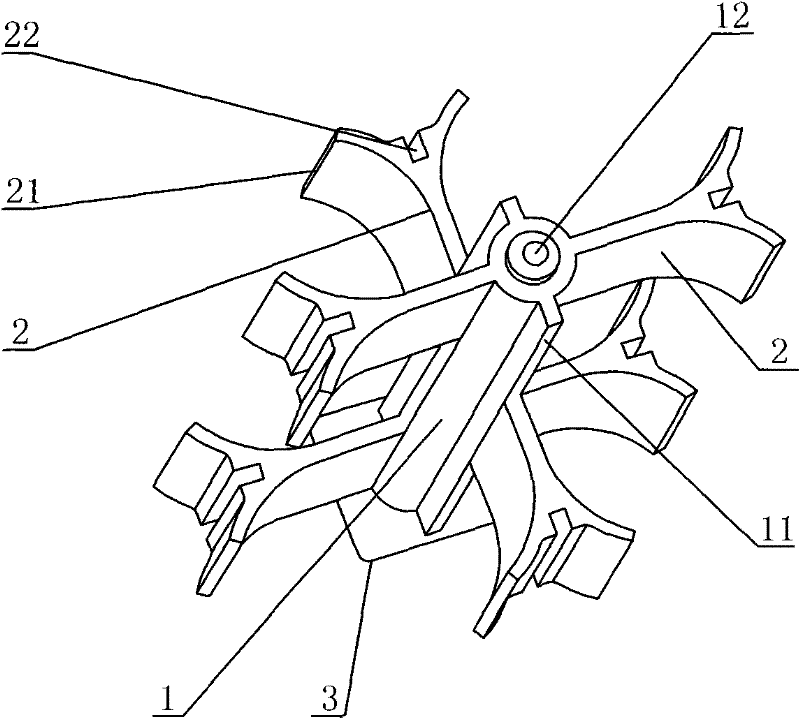

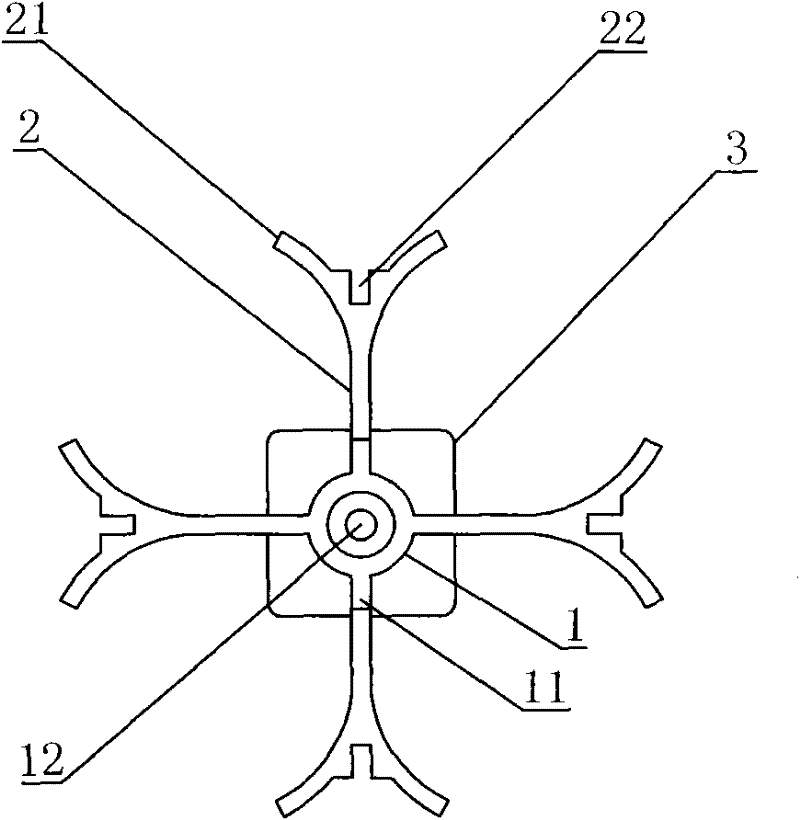

[0035] Such as figure 1 As shown, this embodiment discloses a battery support assembly, the assembly includes a central frame 1, the height of the central frame 1 is the same as that of the battery, so that the battery installed in it will not shake up and down, affecting its working state and use life. A pair of side wings 2 are respectively arranged on the upper, middle and lower parts of the central frame 1, and each pair of side wings 2 is arranged symmetrically on both sides of the central frame 1; Two protective forks 21 are provided at the ends of the side wings 2; an assembly groove 22 is provided at the intersection of the two protective forks 21; a pair of assembly edges 11 are respectively provided at the upper, middle and lower parts of the central frame 1, The pairs of assembling edges 11 are arranged symmetrically on both sides of the central frame 1, and the assembling edges 11 and the three pairs of side wings 2 are intersected in a "ten" shape; the shape and ...

Embodiment 2

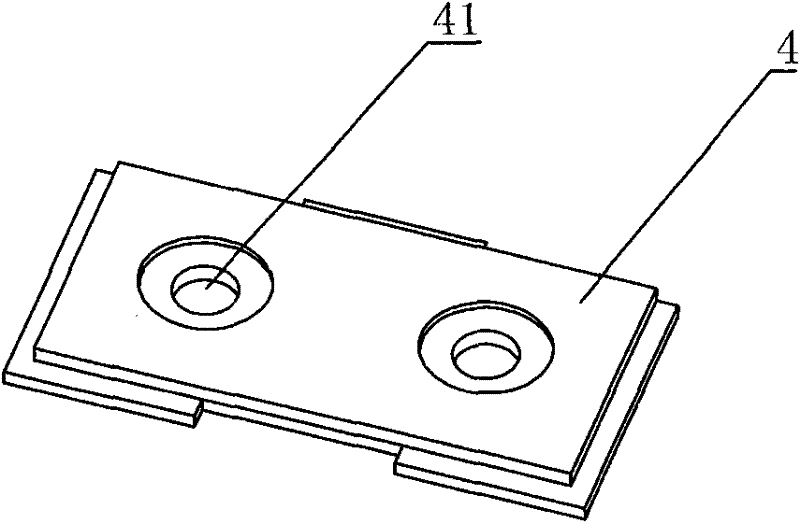

[0041] Such as image 3 As shown, this embodiment discloses a multi-section combined common support for cylindrical batteries made of battery support components. The sides 11 are connected together; the bracket also includes a fixed assembly block 4, on which a counterbore 41 is arranged, and the fixed assembly block 4 is fixedly connected with the battery support assembly by screws.

[0042] Such as image 3 As shown, when the present invention is used, first assemble the battery bracket assembly, then install the battery 5 into the cylindrical battery cavity, and finally cover the fixed assembly block 4 and fix it with screws.

[0043] It should be noted that the figure of this embodiment only schematically shows the combination of 8 battery holder assemblies, and more batteries can be assembled according to different numbers of batteries in the actual assembly process.

[0044] Such as Figure 4 As shown, the fixed assembly block 4 is provided with two counterbores 41 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com