Auxiliary device for large-caliber steel cylinder butt joint

An auxiliary device and large-diameter technology, which is applied in the field of steel cylinder processing, can solve the problems of staggered butt surfaces and the impact of labor intensity and operation safety of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

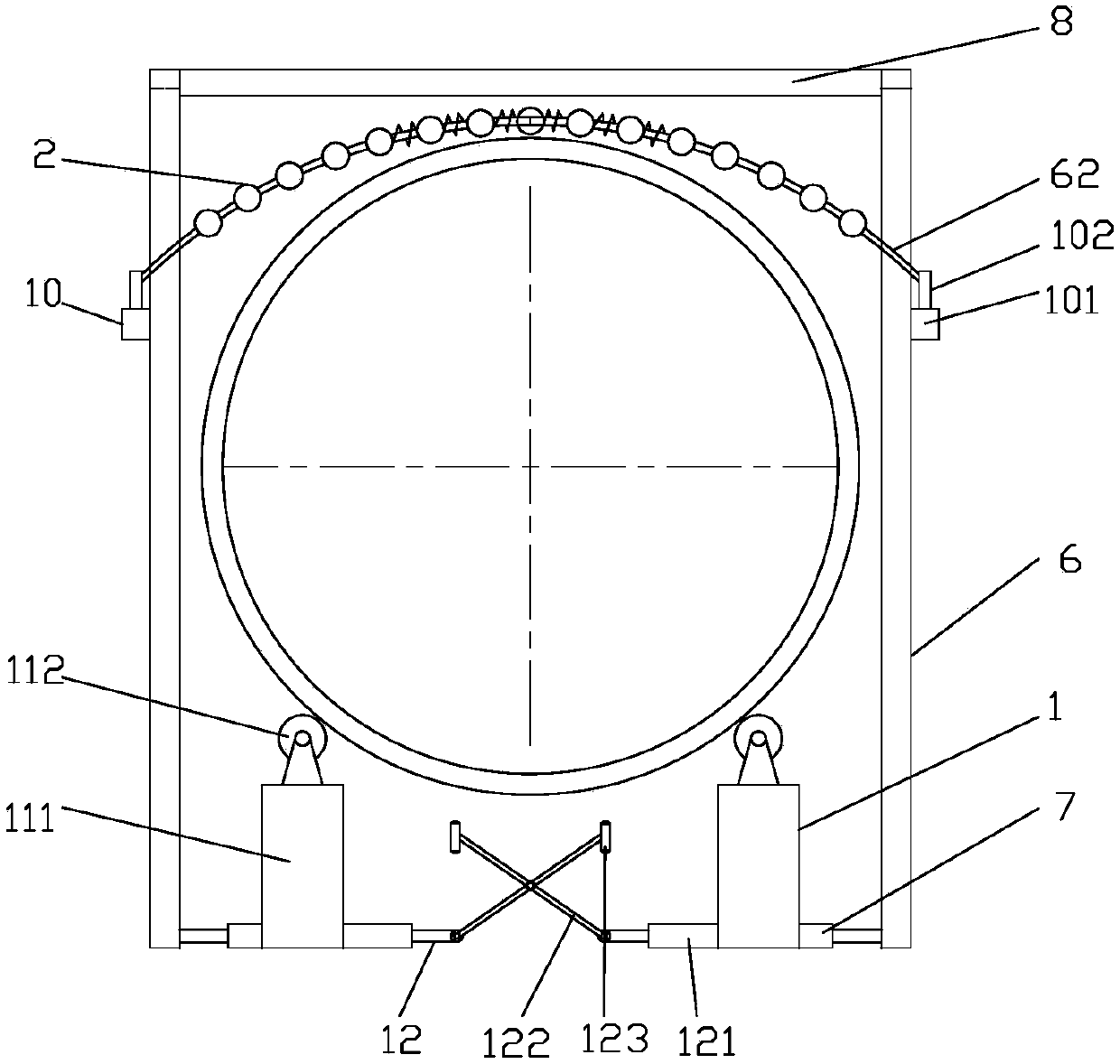

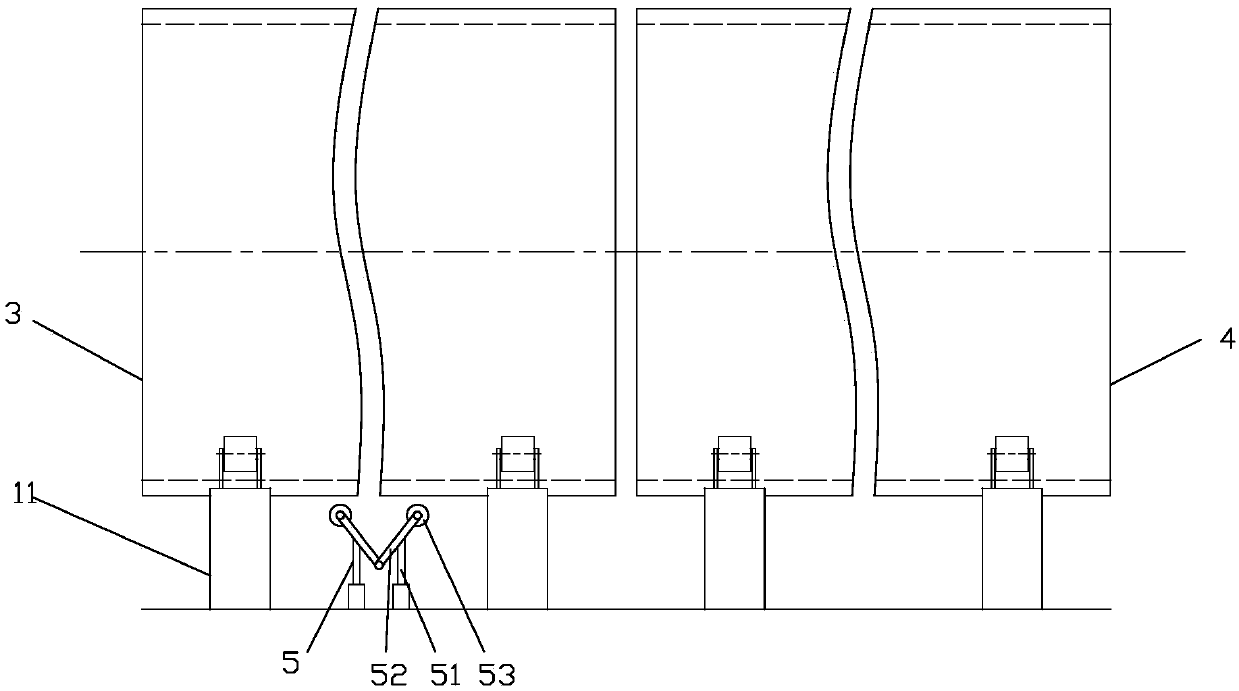

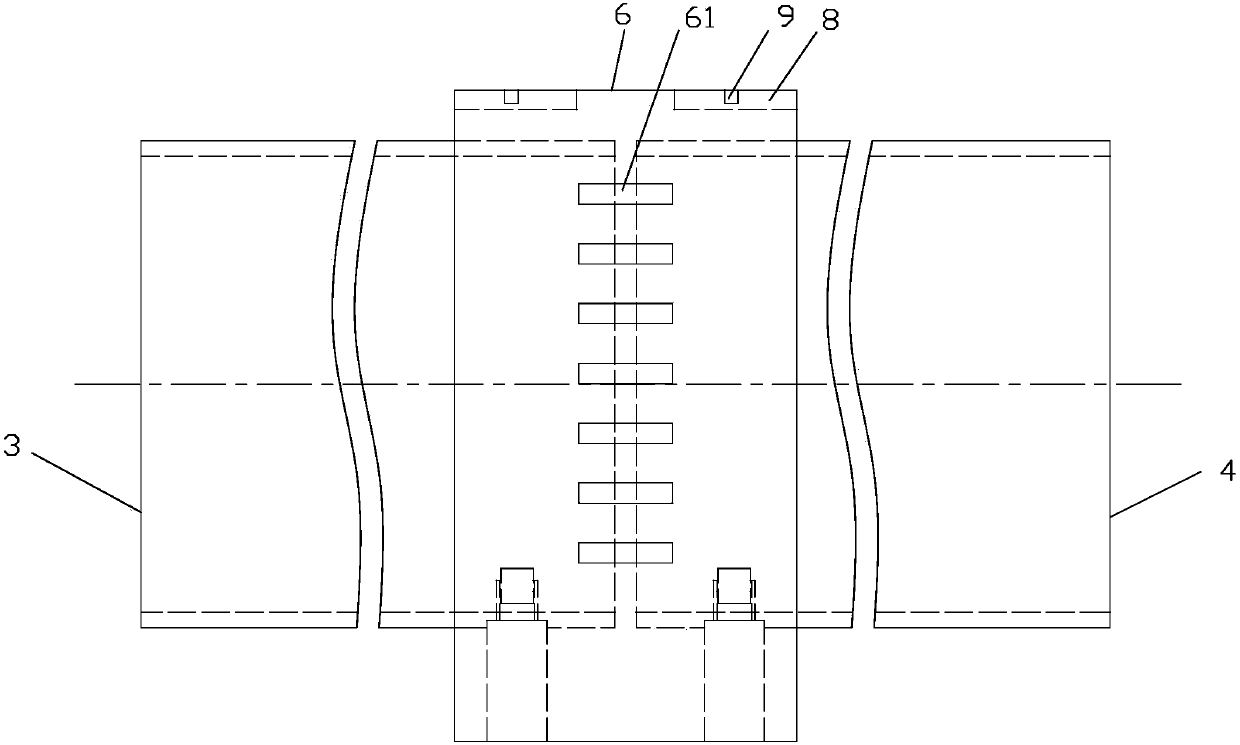

[0030] The present invention as Figure 1-4 As shown, it includes a pair of supporting groups 1 and a pressing mechanism 2,

[0031] A pair of supporting groups are respectively used to support steel cylinder one 3 and steel cylinder two 4,

[0032] The support group includes a pair of parallel brace sets, the brace set includes a rotation support assembly 11 and a translation support assembly 12, the rotation support assembly 11 includes a pair of parallel bases 111, the base A support roller 112 is arranged on the top, and the centerline of the support roller is parallel to the centerline of the steel cylinder;

[0033] The translation support assembly 12 is arranged in a pair of bases, and the translation support assembly includes a pair of hydraulic cylinders 121, a pair of support rods 122 and a pair of rollers 123, and a pair of hydraulic cylinders 12 are respectively arranged on the corresponding bases. On the inner side, a pair of support rods are hingedly arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com