Workbench for iron ring spot welding

A workbench and spot welding technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as eye deformation, glasses that easily compress the bridge of the nose, and adverse eye blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

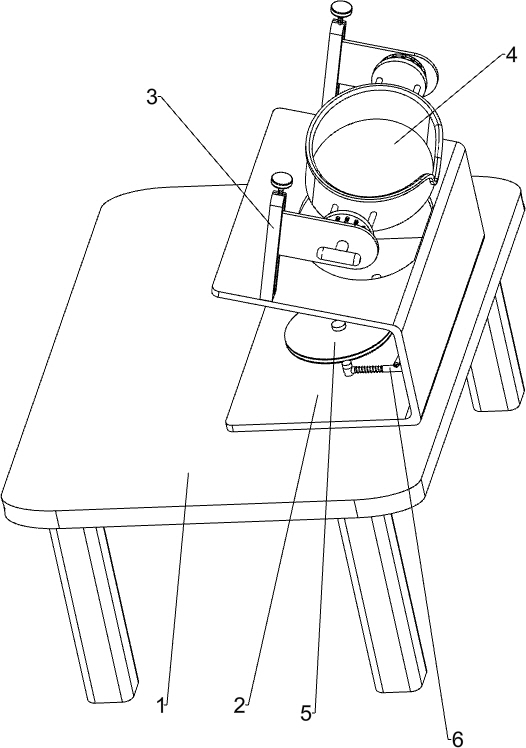

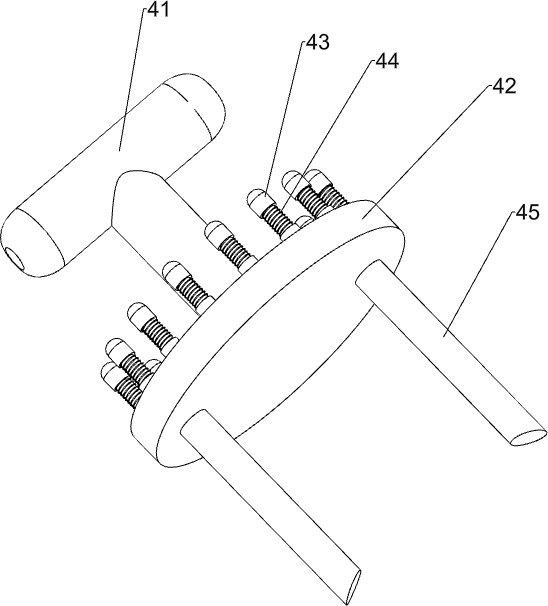

[0023] A workbench for iron ring spot welding, such as Figure 1-4 As shown, it includes a stand 1, a mounting plate 2, a height adjustment device 3, an angle adjustment device 4 and a positioning disc 5. The top right side of the stand 1 is connected with a mounting plate 2, and the top of the mounting plate 2 is equipped with a height adjustment In the device 3, an angle adjustment device 4 is installed on the height adjustment device 3, and a positioning disc 5 is connected to the inner top of the mounting plate 2.

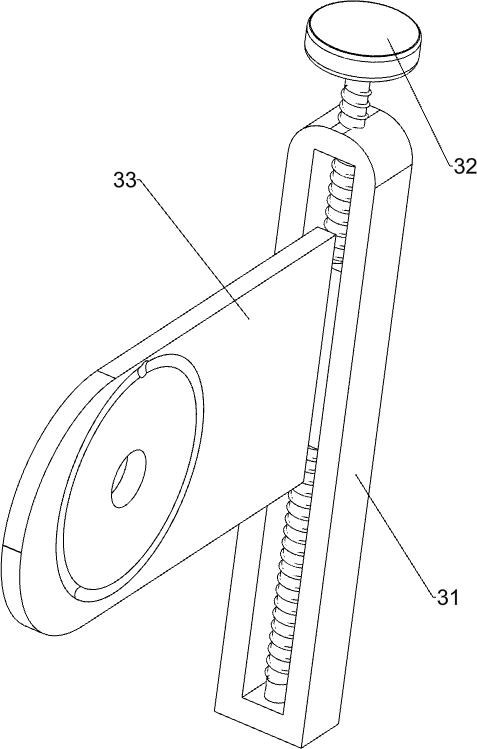

[0024] The height adjustment device 3 includes a slide rail 31, a screw rod 32 and a slide plate 33, the front and rear sides of the mounting plate 2 top are connected with a slide rail 31, the slide rail 31 is slidably connected with a slide block, and the top of the slide rail 31 rotates Type is connected with screw rod 32, and the bottom end of screw rod 32 passes slide block, and screw rod 32 is connected with slide block by the mode of screw connection, an...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 and Figure 5 As shown, a fixing device 6 is also included, and the fixing device 6 includes a second rotating handle 61, a second rotating disk 62, a connecting plate 63, a clamp block 64, a second spring 65 and a second telescopic rod 66, and the positioning disk 5 right The inner top of the mounting plate 2 on the side is rotatably connected with a second turntable 62, the middle of the top of the second turntable 62 is connected with a second rotating handle 61, and the inner top of the mounting plate 2 on the front and rear sides of the second turntable 62 is rotatably connected with a second turntable. Two telescopic rods 66, the inner telescopic rod left end of the second telescopic rod 66 is connected with clip block 64, the inner telescopic rod outer wall of the second telescopic rod 66 is covered with second spring 65, and the left end of second spring 65 is connected with clip block 64, The right end of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com