Mine underground automatic coal mixing system

A technology of coal blending system and mine, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased sales cost, inaccurate proportioning, low coal blending efficiency, etc. The effect of low labor intensity and reduction of equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

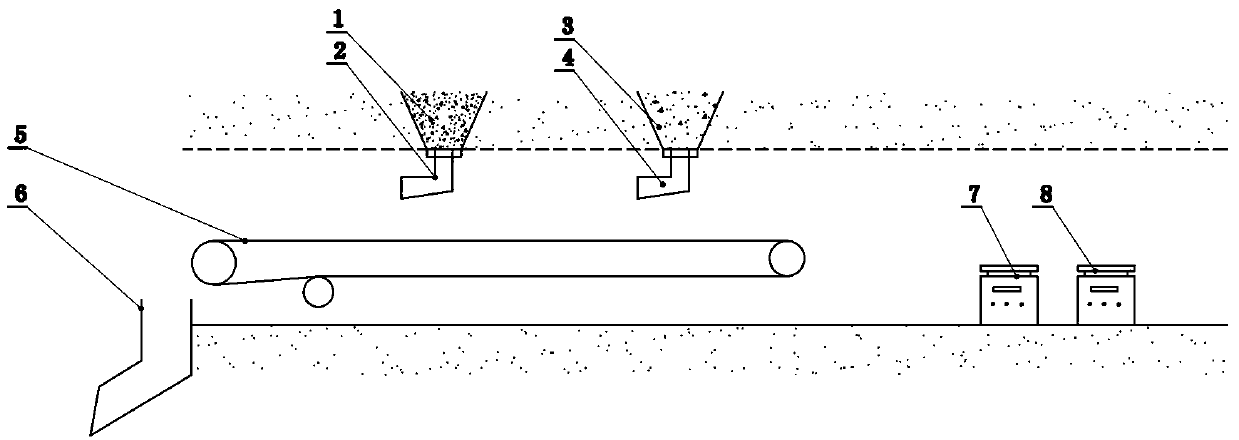

[0018] The main purpose of the mine automatic coal blending system is to control the amount of coal fed by multiple coal feeders in proportion, and then transport it to the metering hopper through the same belt conveyor, and then unload it to the skip after being weighed by the metering hopper 6 , and then lifted to the surface coal bunker through the main shaft hoist. During this series of reloading and lifting processes, raw coals of different coal qualities are evenly blended according to the set ratio to meet the needs of different customers and maximize the mine's benefits. The underground automatic coal blending system of this mine can realize automatic coal blending of raw coal with different coal qualities while loading in the main shaft.

[0019] design principle

[0020] Usually, the raw coal from different mining areas is transported to the main shaft for loading through multiple main transport belt conveyors, and put into two or more coal bunkers above. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com