Novel trolley driving steel wire rope balancing mode and device of bucket-wheel even mixing reclaimer

A balancing device and wire rope technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of uneven force on wire ropes, trolleys slipping, and intertwining, so as to reduce wear and spare parts consumption, run smoothly, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment, embodiment is intended to illustrate the present invention rather than to the further limitation of the present invention, as not departing from the design spirit of the present invention, those of ordinary skill in the art make various solutions to the present invention Deformation, improvement, and retouching all fall within the scope defined by the claims of the present invention.

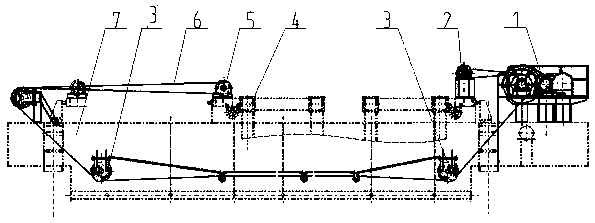

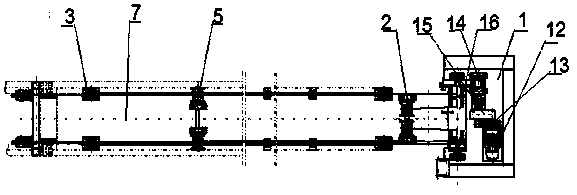

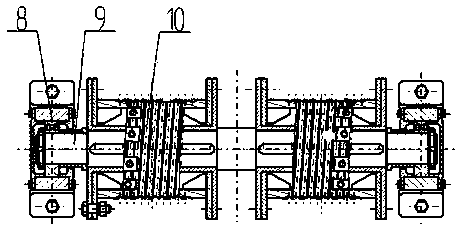

[0024] like figure 1 , figure 2 , image 3 As shown, a new bucket wheel mixing reclaimer trolley drive steel wire rope balance device, including drive system (1), steel wire rope (6), diverting support wheel (3), balance drum I (2), balance roll Tube II (5), drive system (1) is composed of motor (12), coupling (13), brake (14), reducer (15), gear pair, drive drum (16), fixed on the bridge girder At one end of (7), the diverting support roller (3) is scattered and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com