Clear water utilization system and method in slurry pipeline transportation

A technology for pipeline transportation and ore slurry, which is applied in earth-moving drilling, wellbore/well components, construction, etc., can solve the problems of increasing pipeline transportation cost and resource waste, and achieve the effect of reducing transportation cost, waste and water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

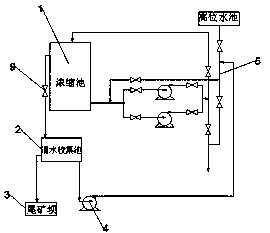

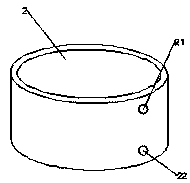

[0021] refer to Figure 1-3 As shown, the present invention provides a clean water utilization system in pulp pipeline transportation, including a thickening tank 1, and a clear water collection tank 2 is built with reinforced concrete around the thickening tank 1. Preferably, the clean water collection tank 2 is designed to be cylindrical and has a volume of 200m³, a water outlet is reserved at the bottom of the clean water collection tank 2 as the water intake 22, and a water outlet is also reserved at the top of the clean water collection tank 2 as the overflow port 21 of the clean water collection tank 2, and a water pump is installed near the water intake 22 4. The water pump 4 is connected to the water intake 22, and the water outlet of the water pump 4 is connected to the main pipeline 5 through a pipeline, and the overflow port 21 at the top of the clear water collection tank 2 is connected to the tailings dam 3 through a pipeline, and is used to drain excess The clear...

Embodiment 2

[0023] On the basis of the above embodiment, another embodiment of the present invention is that in order to ensure that the water pump 4 has strong power, the water pump 4 is a centrifugal clean water pump, the flow rate of the centrifugal clean water pump is 80m³ / h, and the lift is 70m .

Embodiment 3

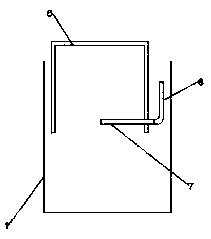

[0025] On the basis of the above-mentioned embodiment, another embodiment of the present invention is that described buoyancy tank 6 is to weld a long 1.5m wide 1m high 0.5m cuboid with a steel plate of 4mm, and this cuboid is inverted on the water surface, for Ensure that the buoyant tank 6 can freely drop 2 meters with the water surface to facilitate water intake. The length of the hose 8 inside the concentration tank 1 is at least 2m, and a valve 9 is installed on the hose 8 outside the concentration tank 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com