A low water-cement ratio cement-based board and its preparation process and application

A technology of preparation process and water-cement ratio, which is applied to low-water-cement ratio cement-based materials and its preparation process and application field, can solve problems such as impact, achieve the effect of reducing moisture content and overcoming uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

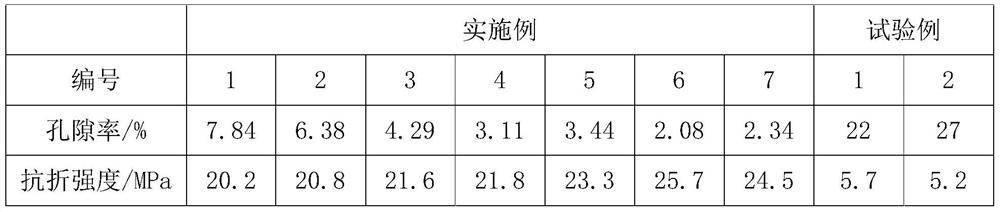

Examples

Embodiment 1

[0035] A preparation process of a low water-cement ratio cement-based board, comprising the following steps:

[0036] (1) 5 parts of water and 25 parts of absolute ethanol are mixed, and stirred for 5min at a speed of 200r / min to form a uniform aqueous ethanol solution;

[0037] (2) mixing 60 parts of cement with the ethanol aqueous solution prepared in step (1), and stirring at a rate of 90r / min for 10min to form a uniform cement slurry;

[0038] (3) the cement slurry obtained in step (2) is formed under a hot press after being placed in a mold, the molding pressure is 12MPa, the heating temperature is 50°C, and the pressure holding time is 20min, and then the obtained cement slurry is placed at a temperature of 25 ℃ and relative humidity of 73% for 20 hours of curing.

Embodiment 2

[0040] A preparation process of a low water-cement ratio cement-based board, comprising the following steps:

[0041] (1) 7 parts of water and 20 parts of absolute ethanol were mixed, and stirred for 5min at a rate of 180r / min to form a uniform aqueous ethanol solution;

[0042] (2) mixing 50 parts of cement with the ethanol aqueous solution prepared in step (1), and stirring for 8min at a rate of 100r / min to form a uniform cement slurry;

[0043] (3) the cement slurry obtained in step (2) is formed under a hot press after being placed in a mold, the molding pressure is 10MPa, the heating temperature is 60°C, and the pressure holding time is 20min, and then the obtained cement slurry is placed at a temperature of 25 ℃, the relative humidity of 75% of the environment curing for 24 hours, that is.

Embodiment 3

[0045] A preparation process of a low water-cement ratio cement-based board, comprising the following steps:

[0046] (1) 6 parts of water and 28 parts of absolute ethanol are mixed, and stirred for 5min at a rate of 180r / min to form a uniform aqueous ethanol solution;

[0047] (2) Mix 70 parts of cement with the ethanol aqueous solution prepared in step (1), stir at a rate of 90 r / min for 10 minutes to form a uniform cement slurry, and then place the cement slurry in a 40° C. environment to dry to a mass drop of about 5%. stop heating;

[0048] (3) the cement slurry obtained after the heat treatment in step (2) is placed in a mold and then molded under a hot press, the molding pressure is 15MPa, the heating temperature is 55°C, and the pressure holding time is 30min, and then the obtained cement slurry is placed in a hot press. Cured for 18 hours in an environment with a temperature of 25°C and a relative humidity of 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com