Device and method for quickly compressing and releasing sample through rubber test

A fast and rubbery technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems affecting the determination of test results, unbalanced force on samples, and time-consuming disassembly and assembly of compression fixtures, etc. , to achieve the effect of quickly disassembling and assembling the compression fixture and solving the unbalanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the relationship between the components in a particular posture (as shown in the accompanying drawings). If the relative position relationship, movement situation, etc. change, the directional indication will change accordingly.

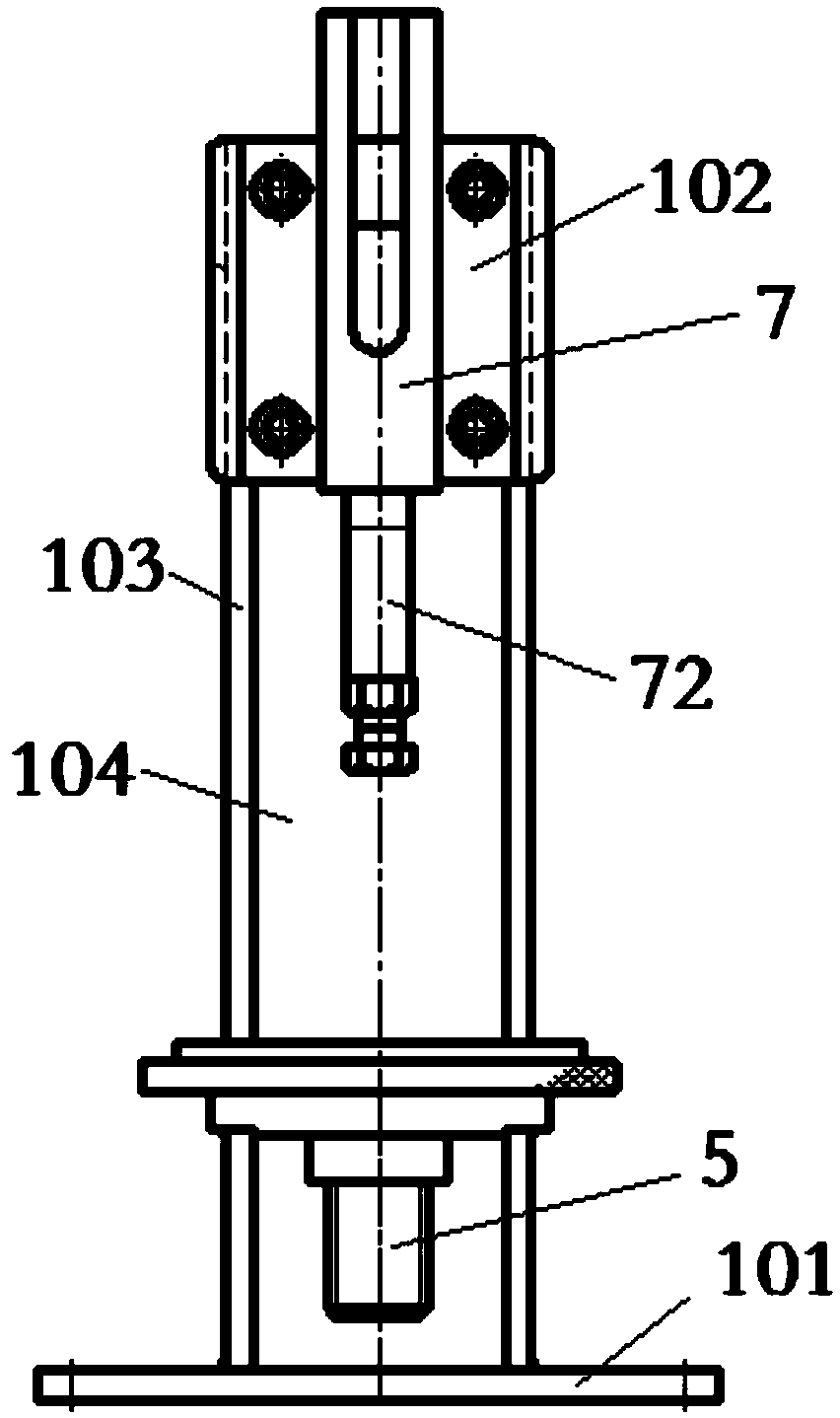

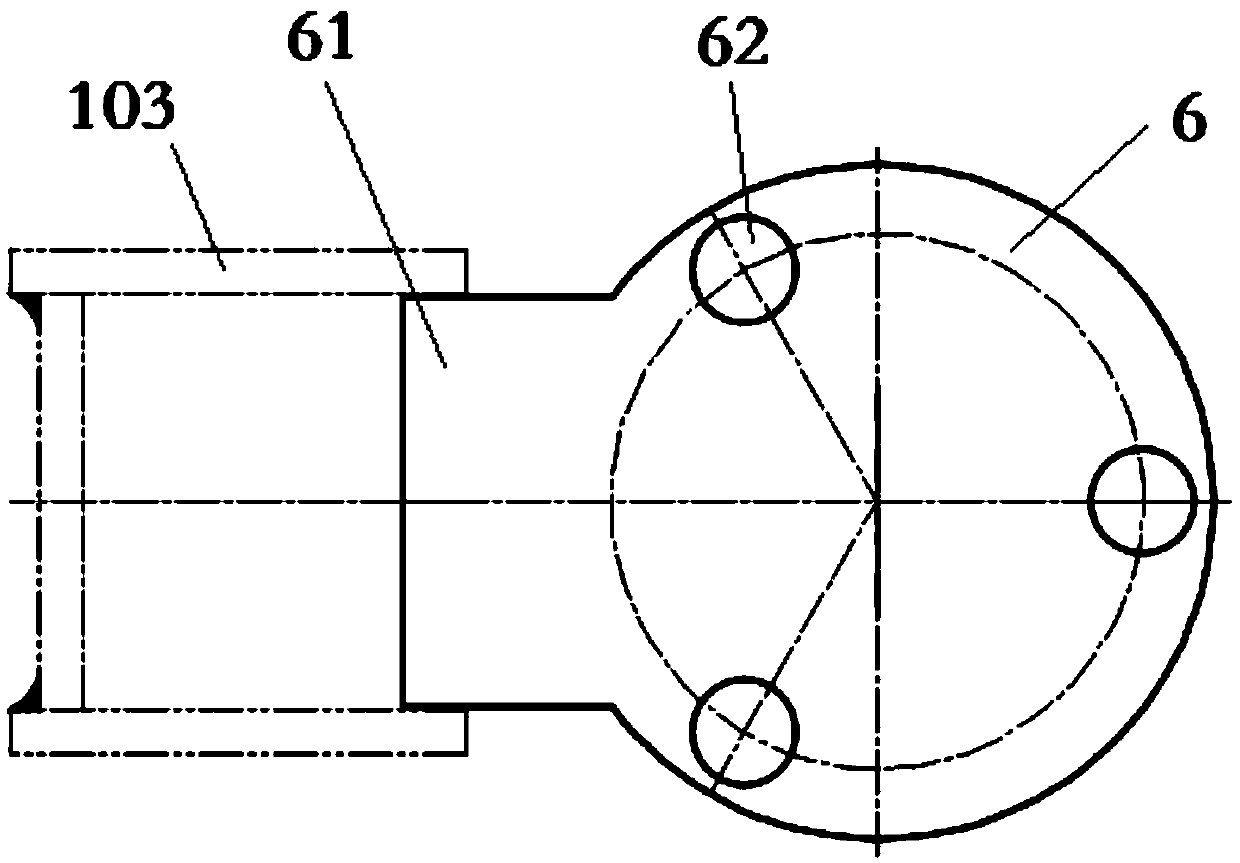

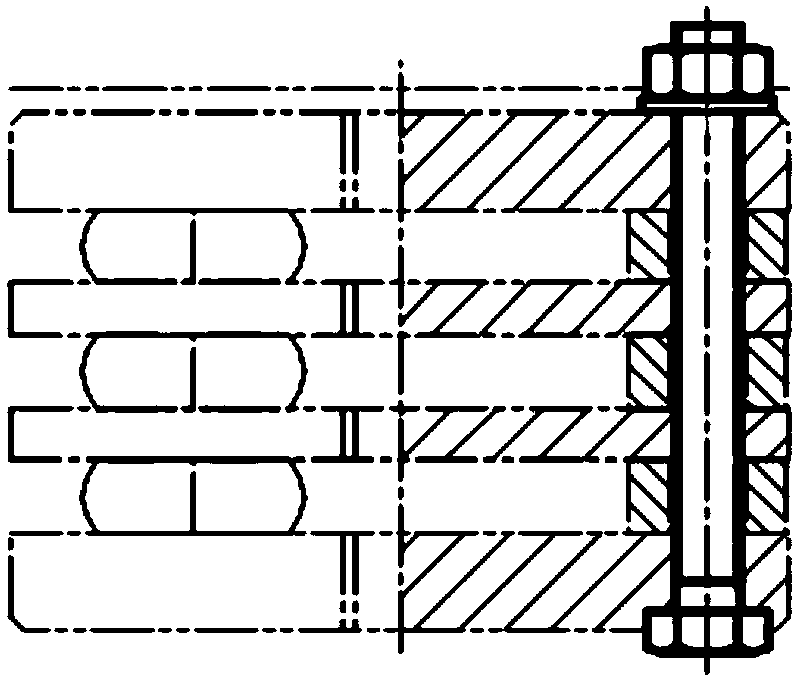

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides a device for quickly compressing and releasing a rubber test specimen, which includes a G-shaped frame 1, a round platform connecting plate 2, a supporting round platform 3, and the lower part of the G-shaped frame 1 is equipped with a round platform connecting plate 2. The round table connecting plate 2 is provided with an internal thread 4, and the bottom of the supporting round table 3 is fixed with a threaded column 5 adapted to the internal thread 4, the threaded column 5 is screwed with the interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com