Assembly parameter optimization method in a shaft hole dynamic assembly process

A technology of dynamic assembly and optimization method, applied in electrical digital data processing, special data processing applications, constraint-based CAD, etc., can solve the problem that the optimal assembly scheme cannot be solved, the detailed geometric features of the shaft hole cannot be characterized, and the assembly features cannot be characterized. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

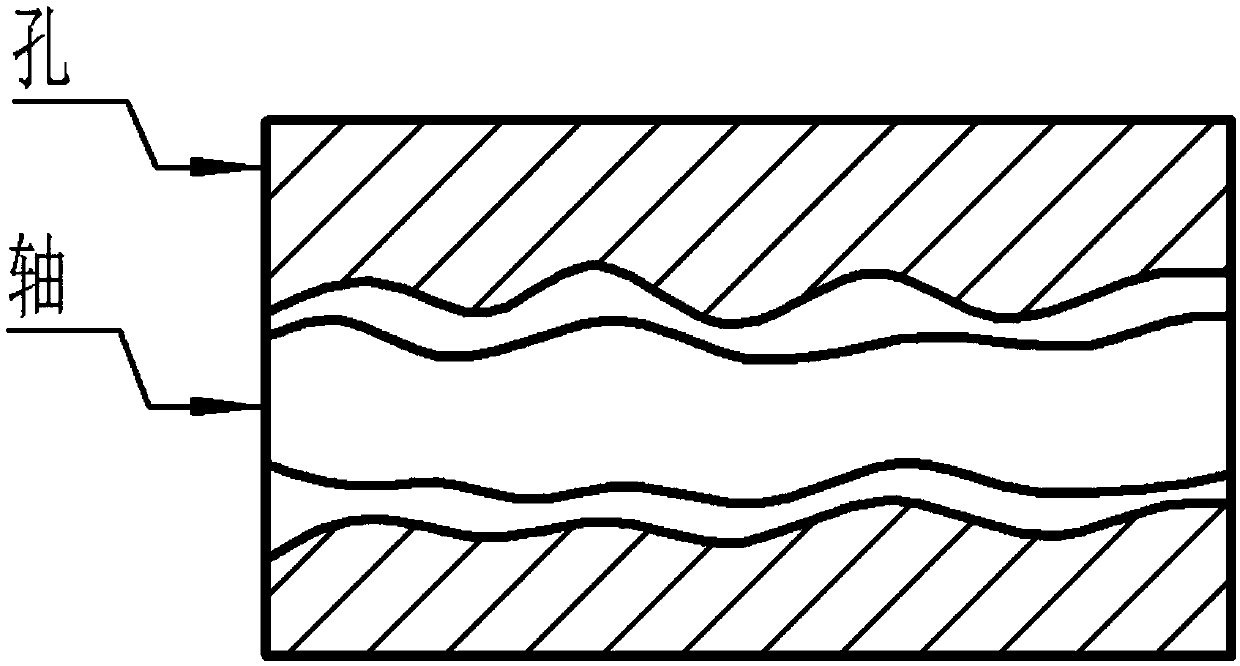

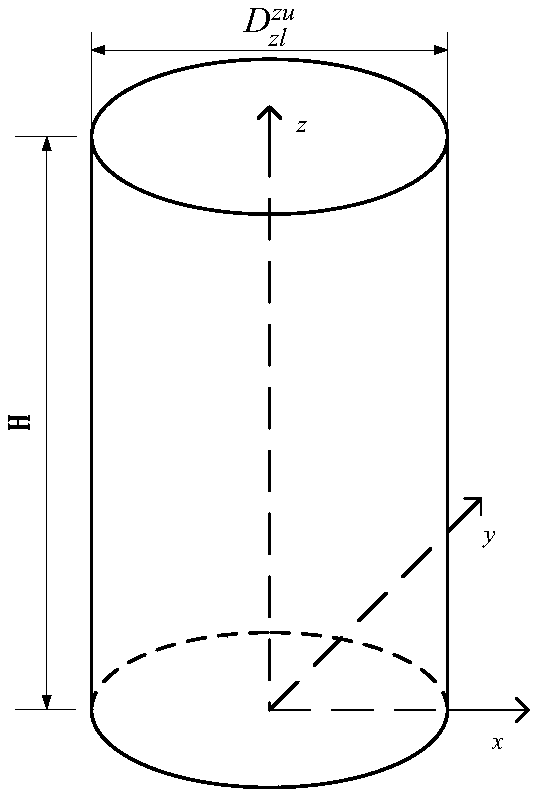

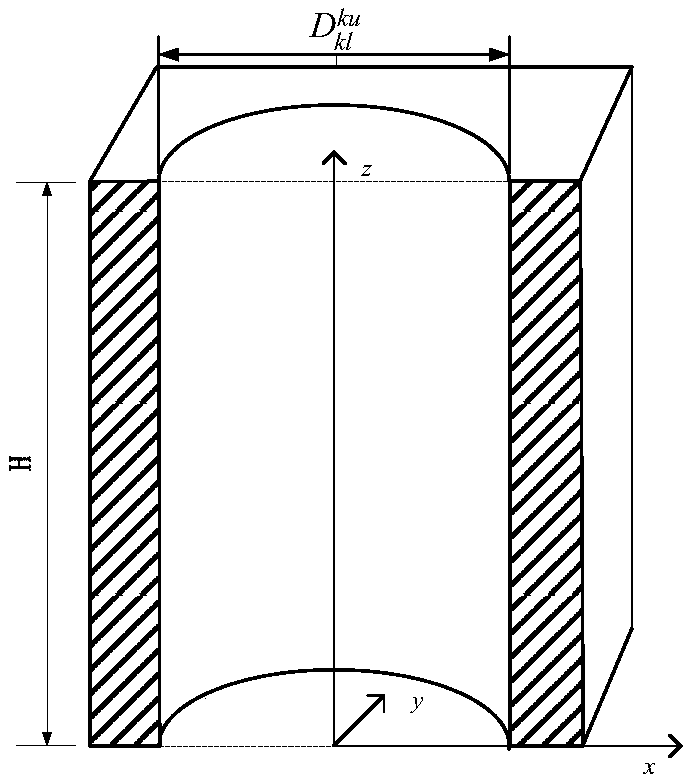

[0029] Such as figure 1 As shown, the geometric appearance of the shaft and the hole is not ideal, so the present invention proposes an assembly method considering the actual part features based on the mathematical expression of the actual geometric features of the shaft and the hole. Through the precise geometric model of the actual features of the part, the actual model of the part is parameterized, and the mathematical model of the spatial geometric relationship of the shaft hole assembly is established. The optimal assembly position is used as the basis for calculating the assembly index, and the space non-interference is used as the calculation constraint to calculate the assembly. Pose, providing process guidance for actual assembly, in which the assembly index provides quantitative indicators for judging the assembly effect, and provides an evaluati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com