Improved suction filtration device with automatic sampling function and suction filtration method

A suction filtration device and automatic sampling technology, applied in separation methods, chemical instruments and methods, fixed filter elements, etc., can solve problems such as reducing experimental efficiency, sample waste, and affecting experimental progress, so as to improve experimental efficiency, Avoid sample waste and the effect of avoiding external contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

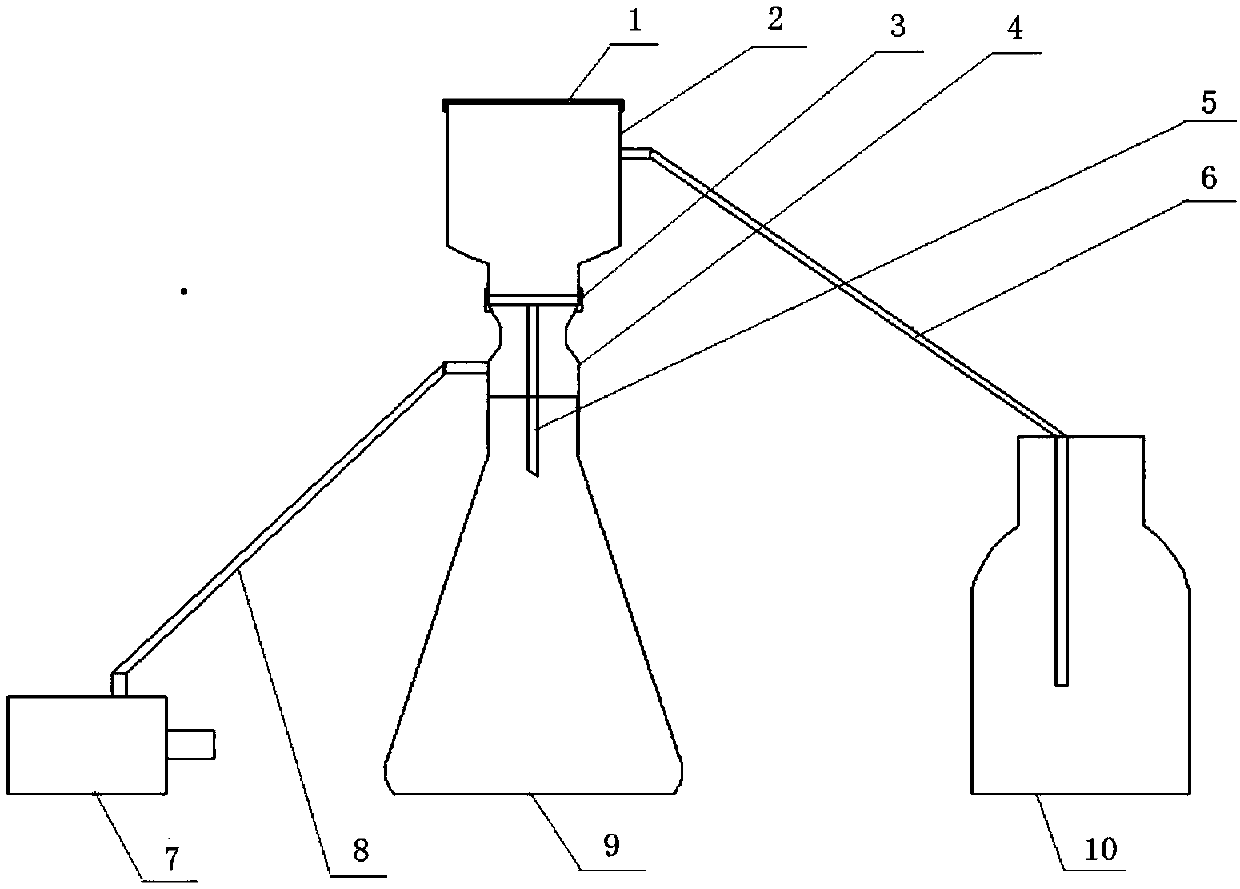

[0035] See figure 1 , an improved suction filtration device capable of automatic sampling, comprising a vacuum pump 7, a filter cup 2, a filter head 4, a suction filtration bottle 9, a liquid inlet pipe 6, an exhaust pipe 8 and an open container 10 for holding the liquid to be filtered The suction filter bottle 9, the filter head 4 and the filter cup 2 are detachably sealed and connected sequentially from bottom to top to form a closed chamber; the filter cup 2 is provided with a liquid inlet, and the liquid inlet pipe 6, one end is connected with the liquid inlet, and the other end is inserted into the open container 10; the side wall of the filter head 4 is provided with a filter head 4 exhaust port; one end of the exhaust pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com