An injection-type soil remediation and treatment integrated equipment

A soil remediation and injection technology, applied in the field of soil pollution control, can solve problems such as ground potholes, limited depth of action, and complicated steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

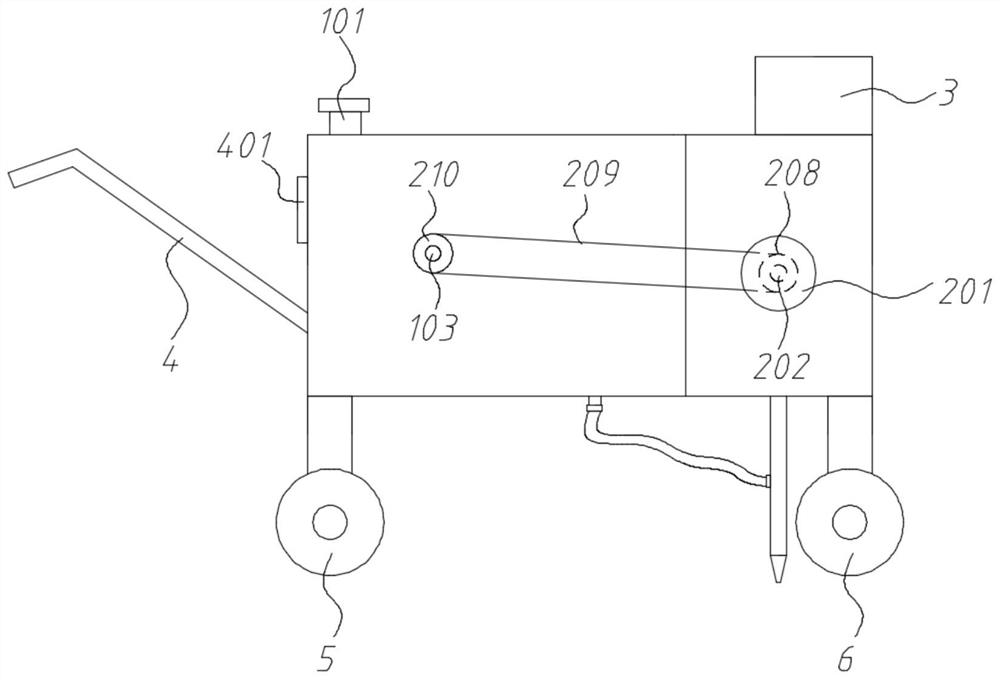

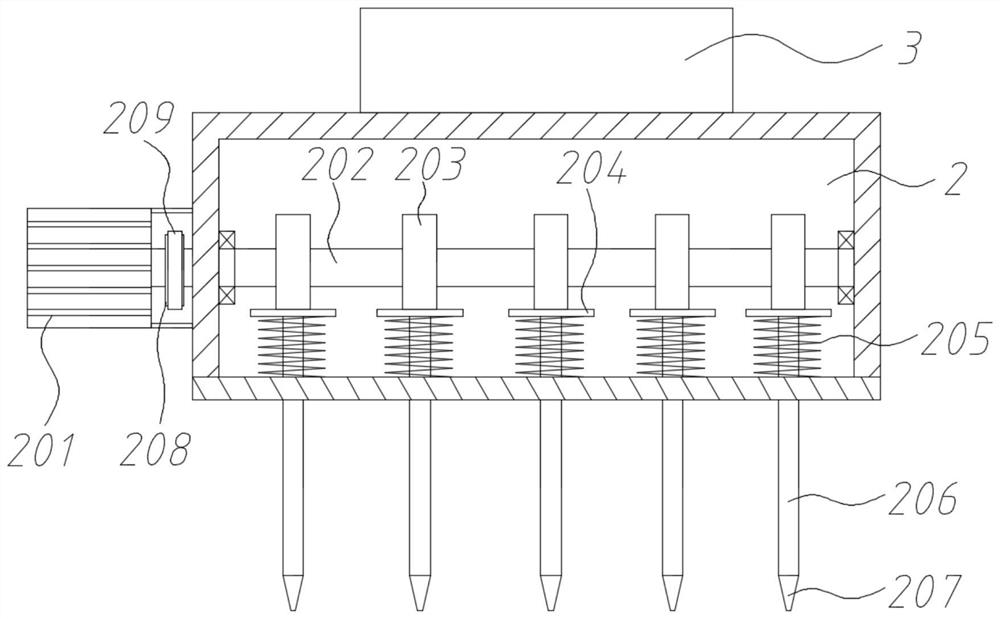

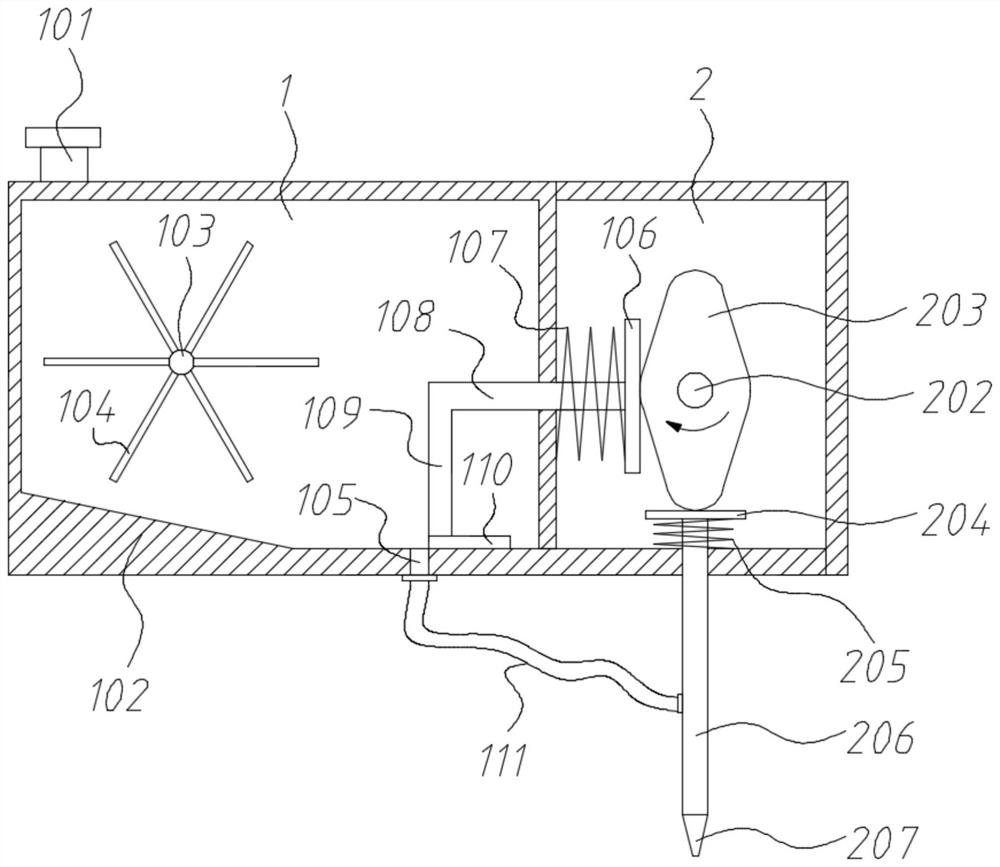

[0039] An injection-type integrated equipment for soil remediation and treatment, including a housing, a power supply 3, a No. 1 roller assembly 5, and a No. 2 roller assembly 6;

[0040] A partition is fixed in the shell, which divides the inner cavity of the shell into a drug storage chamber 1 and a working chamber 2; the working chamber 2 is equipped with a No. 1 rotating shaft 202 in the front and rear directions, and a number of shuttle-shaped cams are evenly spaced on the No. 1 rotating shaft 202 203; a No. 1 pressing plate 204 is arranged below the shuttle cam 203, and a No. 1 spring 205 is connected between the No. 1 pressing plate 204 and the bottom plate of the working chamber 2. The No. 1 pressing plate 204 is connected downward with an injection tube 206, and the bottom end of the injection tube 206 passes through the working chamber. Cavity 2; the left side of shuttle cam 203 is provided with No. 2 pressing plate 106, is connected with No. 2 spring 107 between No. ...

Embodiment 2

[0045] An injection-type integrated equipment for soil remediation and treatment, including a housing, a power supply 3, a No. 1 roller assembly 5, and a No. 2 roller assembly 6;

[0046] A partition is fixed in the shell, which divides the inner cavity of the shell into a drug storage chamber 1 and a working chamber 2; the working chamber 2 is equipped with a No. 1 rotating shaft 202 in the front and rear directions, and a number of shuttle-shaped cams are evenly spaced on the No. 1 rotating shaft 202 203; a No. 1 pressing plate 204 is arranged below the shuttle cam 203, and a No. 1 spring 205 is connected between the No. 1 pressing plate 204 and the bottom plate of the working chamber 2. The No. 1 pressing plate 204 is connected downward with an injection tube 206, and the bottom end of the injection tube 206 passes through the working chamber. Cavity 2; the left side of shuttle cam 203 is provided with No. 2 pressing plate 106, is connected with No. 2 spring 107 between No. ...

Embodiment 3

[0052] An injection-type integrated equipment for soil remediation and treatment, including a housing, a power supply 3, a No. 1 roller assembly 5, and a No. 2 roller assembly 6;

[0053] A partition is fixed in the shell, which divides the inner cavity of the shell into a drug storage chamber 1 and a working chamber 2; the working chamber 2 is equipped with a No. 1 rotating shaft 202 in the front and rear directions, and a number of shuttle-shaped cams are evenly spaced on the No. 1 rotating shaft 202 203; a No. 1 pressing plate 204 is arranged below the shuttle cam 203, and a No. 1 spring 205 is connected between the No. 1 pressing plate 204 and the bottom plate of the working chamber 2. The No. 1 pressing plate 204 is connected downward with an injection tube 206, and the bottom end of the injection tube 206 passes through the working chamber. Cavity 2; the left side of shuttle cam 203 is provided with No. 2 pressing plate 106, is connected with No. 2 spring 107 between No. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap